Nissan Frontier D22. Manual - part 484

DTC P1147, P1167 HO2S2

EC-1039

[VG33E]

C

D

E

F

G

H

I

J

K

L

M

A

EC

5.

CHECK HO2S2 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch “OFF”.

2.

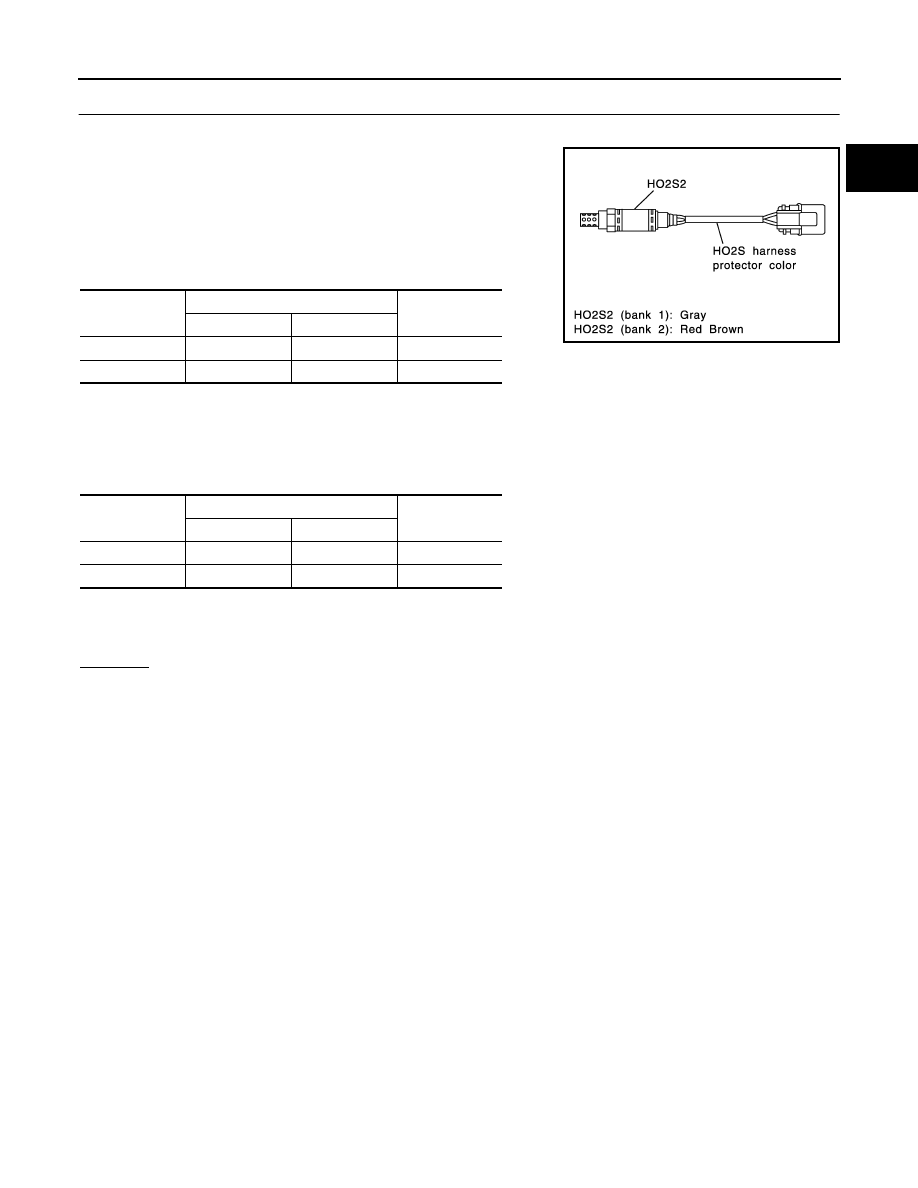

Check heated oxygen sensor 2 harness protector color.

3.

Disconnect corresponding heated oxygen sensor 2 harness

connector.

4.

Disconnect ECM harness connector.

5.

Check harness continuity between ECM terminal and HO2S2

terminal as follows.

Refer to Wiring Diagram.

6.

Check harness continuity between ECM terminal or HO2S2 terminal and ground as follows.

Refer to Wiring Diagram.

7.

Also check harness for short to power.

OK or NG

OK (With CONSULT-II)>>GO TO 6.

OK (Without CONSULT-II)>>GO TO 7.

NG

>> Repair open circuit or short to ground or short to power in harness or connectors.

DTC

Terminals

Bank

ECM

Sensor

P1147

56

1

Bank 1

P1167

57

1

Bank 2

Continuity should exist.

PBIB1423E

DTC

Terminals

Bank

ECM or sensor

Ground

P1147

56 or 1

Ground

Bank 1

P1167

57 or 1

Ground

Bank 2

Continuity should not exist.