Nissan Frontier D22. Manual - part 460

DTC P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-943

[VG33E]

C

D

E

F

G

H

I

J

K

L

M

A

EC

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than the ECM terminals, such as the ground.

Diagnostic Procedure

UBS00DLJ

1.

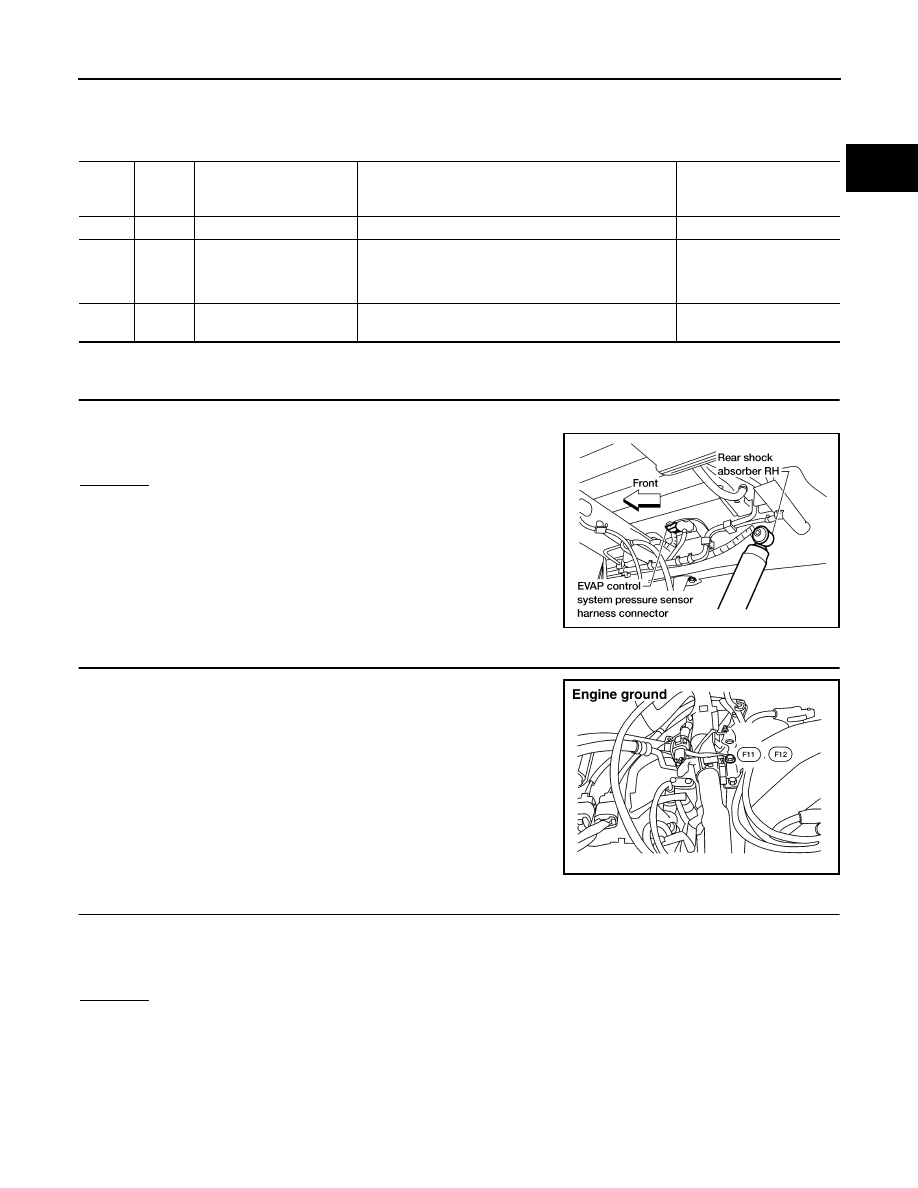

CHECK RUBBER TUBE

1.

Turn ignition switch OFF.

2.

Check rubber tube connected to the sensor for clogging, vent,

kink, disconnection or improper connection.

OK or NG

OK

>> GO TO 2.

NG

>> Reconnect, repair or replace.

2.

RETIGHTEN GROUND SCREWS

1.

Loosen and retighten engine ground screws.

>> GO TO 3.

3.

CHECK CONNECTOR

1.

Disconnect EVAP control system pressure sensor harness connector.

2.

Check sensor harness connector for water.

Water should not exist.

OK or NG

OK

>> GO TO 4.

NG

>> Repair or replace harness connector.

TER-

MINAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

42

B/W

Sensor power supply

[Ignition switch: ON]

Approximately 5V

43

BR

Sensor ground

[Engine is running]

●

Warm-up condition

●

Idle speed

Approximately 0V

62

Y

EVAP control system pres-

sure sensor

[Ignition switch: ON]

Approximately 1.8 - 4.8V

AEC651A

BBIA0418E