Nissan Frontier D22. Manual - part 449

DTC P0420, P0430 THREE WAY CATALYST FUNCTION

EC-899

[VG33E]

C

D

E

F

G

H

I

J

K

L

M

A

EC

5.

CHECK INJECTORS

1.

Refer to Wiring Diagram for Injectors,

.

2.

Stop engine and then turn ignition switch ON.

3.

Check voltage between ECM terminals 102, 104, 106, 109, 111

and 113 and ground with CONSULT-II or tester.

OK or NG

OK

>> GO TO 6.

NG

>> Perform

6.

CHECK IGNITION SPARK

1.

Turn ignition switch OFF.

2.

Disconnect ignition wire from spark plug.

3.

Connect a known good spark plug to the ignition wire.

4.

Place end of spark plug against a suitable ground and crank engine.

5.

Check for spark.

OK or NG

OK

>> GO TO 8.

NG

>> GO TO 7.

7.

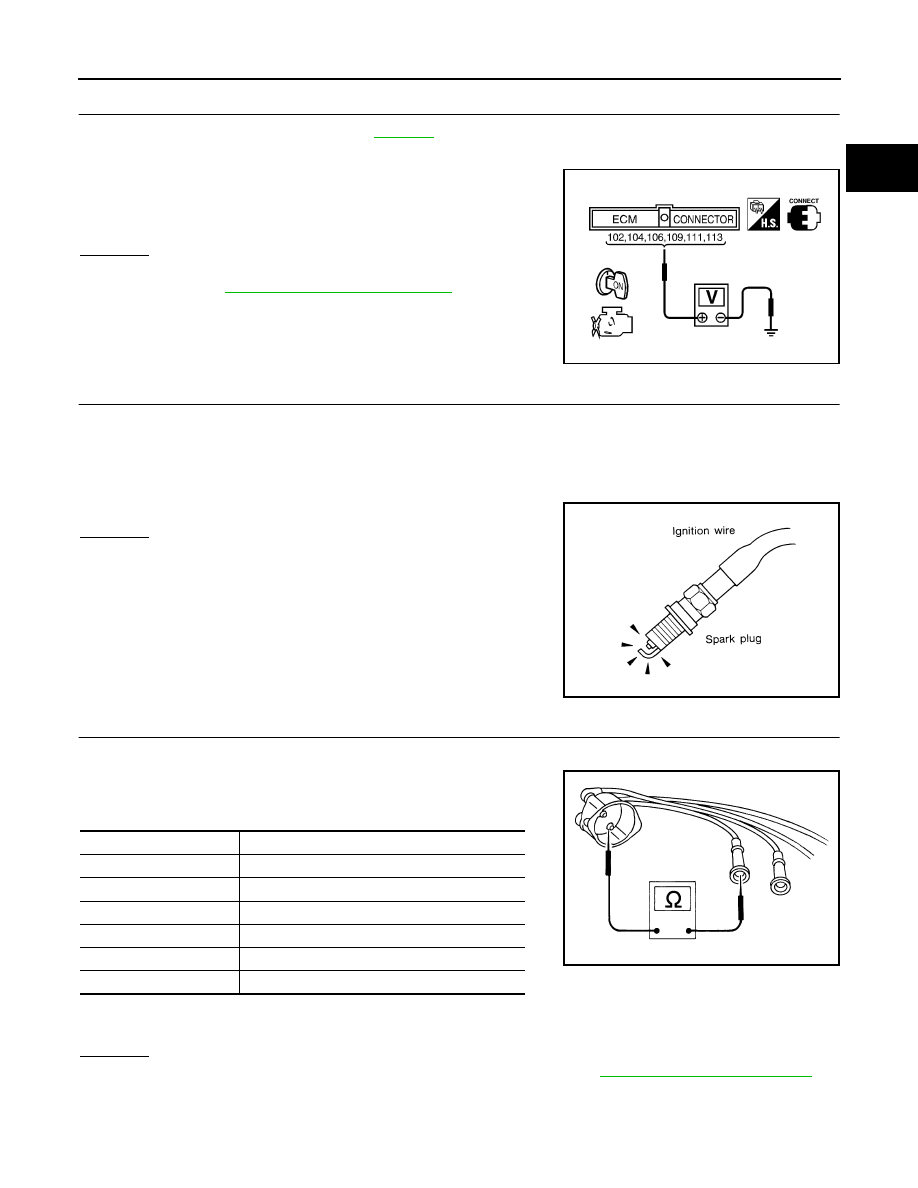

CHECK IGNITION WIRES

1.

Inspect wires for cracks, damage, burned terminals and for improper fit.

2.

Measure the resistance of wires to their distributor cap terminal.

Move each wire while testing to check for intermittent breaks.

Resistance:

If the resistance exceeds the above specification, inspect ignition wire to distributor cap connection. Clean

connection or replace the ignition wire with a new one.

OK or NG

OK

>> Check ignition coil, power transistor and their circuits. Refer to

NG

>> Replace.

Battery voltage should exist.

SEF711U

SEF282G

Cylinder No.

Resistance k

Ω [at 25°C (77°F)]

1

Approx. 6.5

2

Approx. 10.0

3

Approx. 8.5

4

Approx. 12.5

5

Approx. 8.5

6

Approx. 11.0

SEF174P