Nissan Frontier D22. Manual - part 393

TROUBLE DIAGNOSIS

EC-675

[VG33E]

C

D

E

F

G

H

I

J

K

L

M

A

EC

*: Any mode except OFF, ambient air temperature is above 25

°C (77°F).

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

CONSULT-II Function

UBS00DFA

FUNCTION

*: The following emission-related diagnostic information is cleared when the ECM memory is erased.

●

Diagnostic trouble codes

●

1st trip diagnostic trouble codes

●

Freeze frame data

121

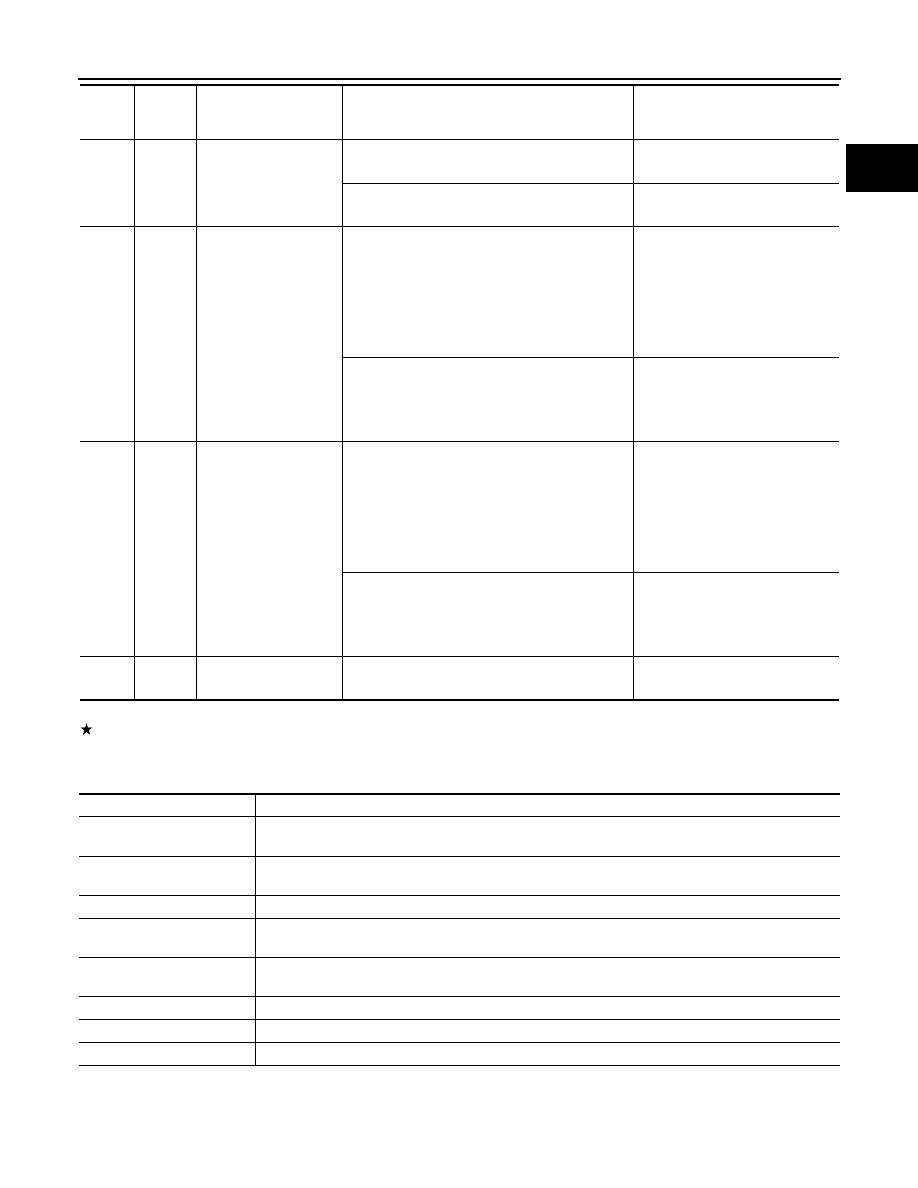

BR

Heated oxygen sensor

1 heater (bank 2)

[Engine is running]

●

Engine speed is below 2,800 rpm

Approximately 0.4V

[Engine is running]

●

Engine speed is above 2,800 rpm

BATTERY VOLTAGE

(11 - 14V)

122

R/B

Heated oxygen sensor

2 heater (bank 1)

[Engine is running]

●

Engine speed is below 3,600 rpm after the fol-

lowing conditions are met

–

Warm-up condition

–

Keeping the engine speed between 3,500 and

4,000 rpm for 1 minute and at idle for 1 minute

under no load

0 - 1.0V

[Ignition switch: ON]

●

Engine stopped

[Engine is running]

●

Engine speed is above 3,600 rpm

BATTERY VOLTAGE

(11 - 14V)

123

R/Y

Heated oxygen sensor

2 heater (bank 2)

[Engine is running]

●

Engine speed is below 3,600 rpm after the fol-

lowing conditions are met

–

Warm-up condition

–

Keeping the engine speed between 3,500 and

4,000 rpm for 1 minute and at idle for 1 minute

under no load

0 - 1.0V

[Ignition switch: ON]

●

Engine stopped

[Engine is running]

●

Engine speed is above 3,600 rpm

BATTERY VOLTAGE

(11 - 14V)

124

B/R

ECM ground

[Engine is running]

●

Idle speed

Engine ground

TER-

MINAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

Diagnostic test mode

Function

Work support

This mode enables a technician to adjust some devices faster and more accurately by following the

indications on the CONSULT-II unit.

Self-diagnostic results

Self-diagnostic results such as 1st trip DTC, DTCs and 1st trip freeze frame data or freeze frame data

can be read and erased quickly.*

Data monitor

Input/Output data in the ECM can be read.

Data monitor (SPEC)

Input/Output specification of the basic fuel schedule, AFM, A/F feedback control value and the other

data monitor items can be read.

Active test

Diagnostic Test Mode in which CONSULT-II drives some actuators apart from the ECMs and also

shifts some parameters in a specified range.

DTC & SRT confirmation

The status of system monitoring tests and the self-diagnosis status/result can be confirmed.

Function test

This mode is used to inform customers when their vehicle condition requires periodic maintenance.

ECM part number

ECM part number can be read.