Nissan Frontier D22. Manual - part 345

DTC P1448 EVAP CANISTER VENT CONTROL VALVE

EC-483

[KA24DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

11. Make sure of the following.

If the result is NG, go to

EC-483, "Diagnostic Procedure"

If the result is OK, go to “Diagnostic Procedure” for DTC P0442,

Overall Function Check

UBS00DBP

Use this procedure to check the overall function of the EVAP canister vent control valve circuit. During this

check, a 1st trip DTC might not be confirmed.

WITH GST

1.

Disconnect hose from water separator.

2.

Disconnect EVAP canister vent control valve harness connector.

3.

Verify the following.

If the result is NG, go to

EC-483, "Diagnostic Procedure"

If the result is OK, perform trouble diagnosis for DTC P0442.

Refer to

Diagnostic Procedure

UBS00DBQ

1.

CHECK RUBBER TUBE

1.

Turn ignition switch OFF.

2.

Check disconnection or obstruction of rubber tube connected to EVAP canister vent control valve.

OK or NG

OK

>> GO TO 2.

NG

>> Repair or clean rubber tube.

2.

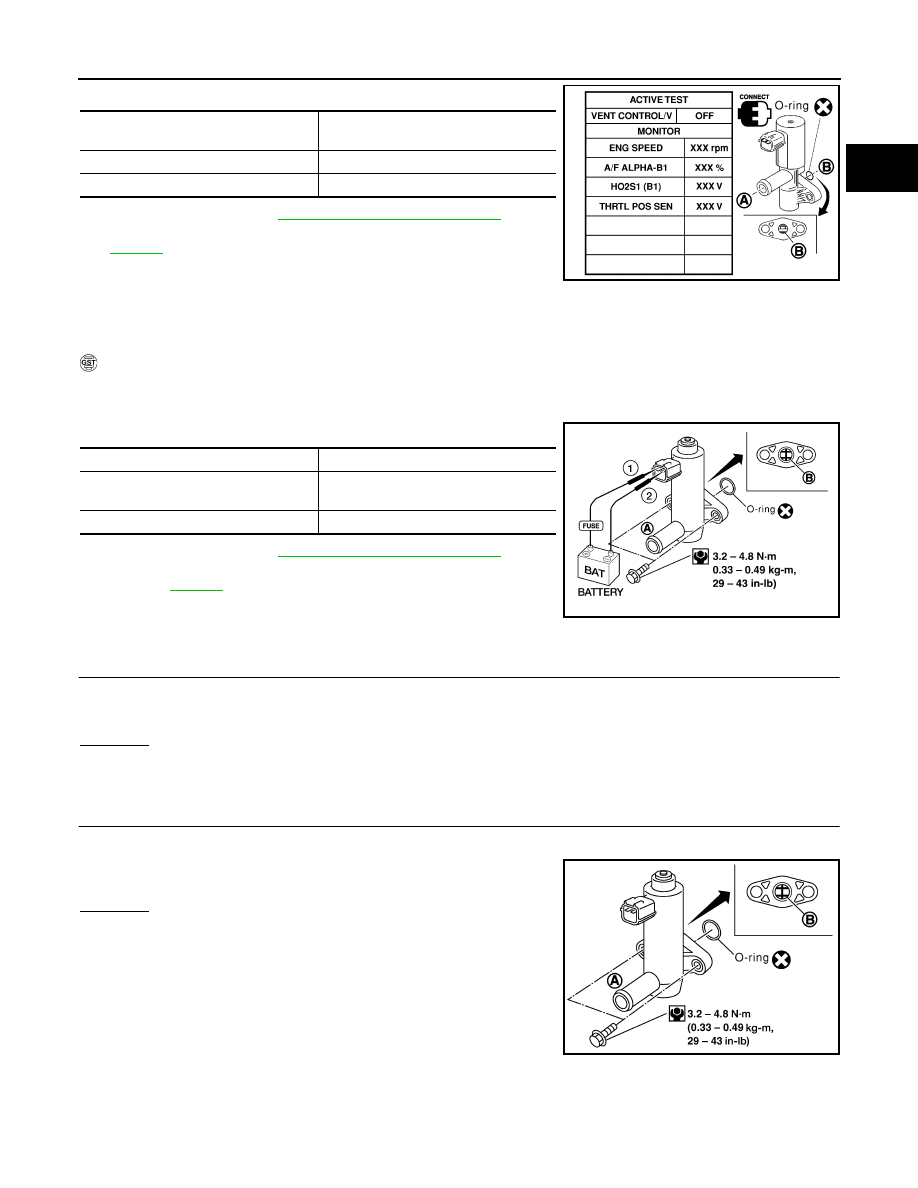

CHECK EVAP CANISTER VENT CONTROL VALVE-I

1.

Remove EVAP canister vent control valve from EVAP canister.

2.

Check portion B of EVAP canister vent control valve for being

rusted.

OK or NG

OK

>> GO TO 3.

NG

>> Replace EVAP canister vent control valve.

Condition

Air passage continuity between A and

B

Touching “ON”

No

Touching “OFF”

Yes

SEF805Y

Condition

Air passage continuity

12V direct current supply between ter-

minals 1 and 2

No

No supply

Yes

BBIA0309E

BBIA0308E