Nissan Frontier D22. Manual - part 330

DTC P1144 HO2S1

EC-423

[KA24DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

2.

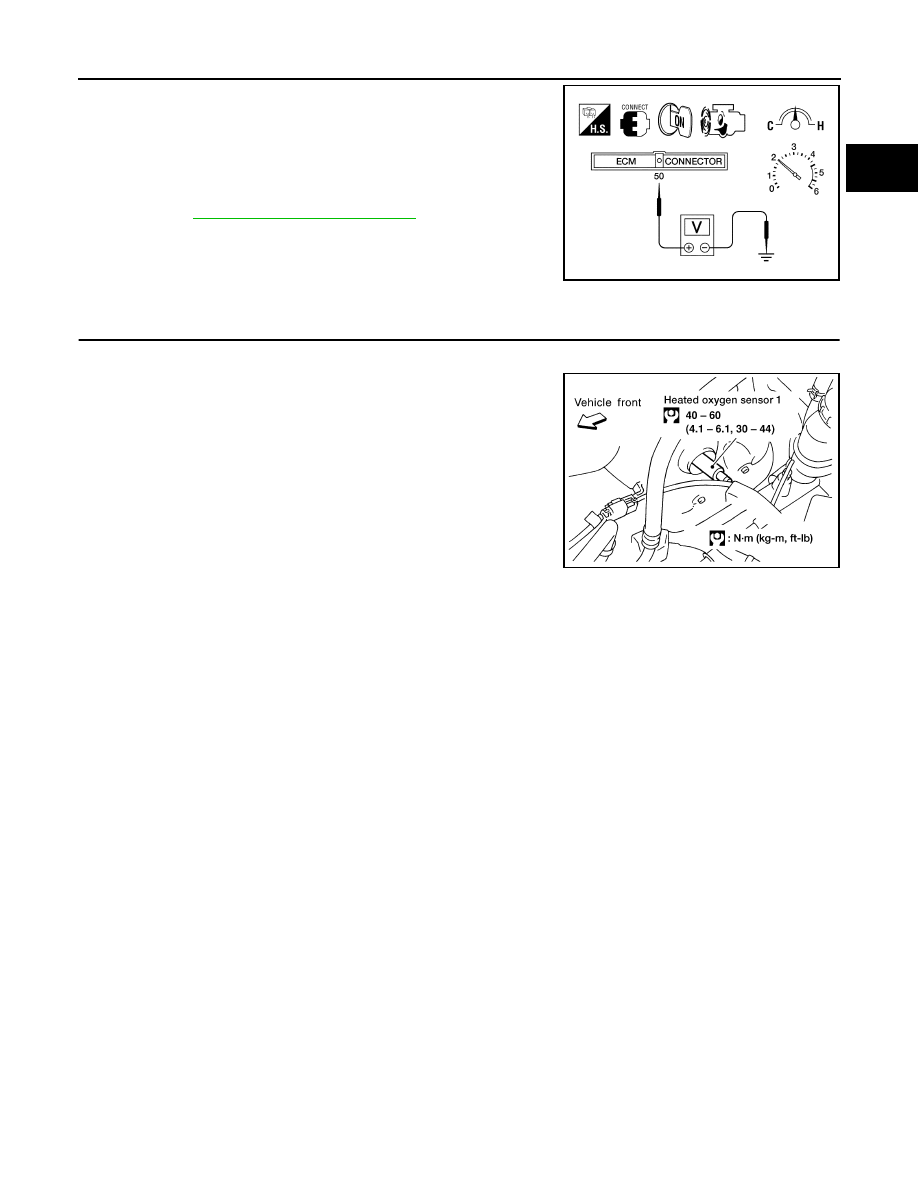

Set voltmeter probes between ECM terminal 50 (Heated oxygen

sensor 1 signal) and ECM ground.

3.

Check the following with engine speed held at 2,000 rpm con-

stant under no load.

–

The maximum voltage is below 0.8V at least 1 time.

–

The minimum voltage is below 0.35V at least 1 time.

4.

If NG, go to

EC-423, "Diagnostic Procedure"

Diagnostic Procedure

UBS00DA0

1.

RETIGHTEN HEATED OXYGEN SENSOR 1

1.

Turn ignition switch OFF.

2.

Loosen and retighten heated oxygen sensor 1.

>> GO TO 2.

AEC873A

Tightening torque

: 40 - 60 N·m

(4.1 - 6.1 kg-m, 30 - 44 ft-lb)

BBIA0429E