Nissan Frontier D22. Manual - part 258

DTC P0037, P0038 HO2S2 HEATER

EC-135

[KA24DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

3.

CHECK OUTPUT SIGNAL CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check harness continuity between heated oxygen sensor 2 terminal 3 and ECM terminal 122.

Refer to Wiring Diagram.

4.

Also check harness for short to ground or short to power.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 4.

4.

DETECT MALFUNCTIONING PART

Check the following.

●

Harness connectors M81, F36

●

Harness for open or short between heated oxygen sensor 2 and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.

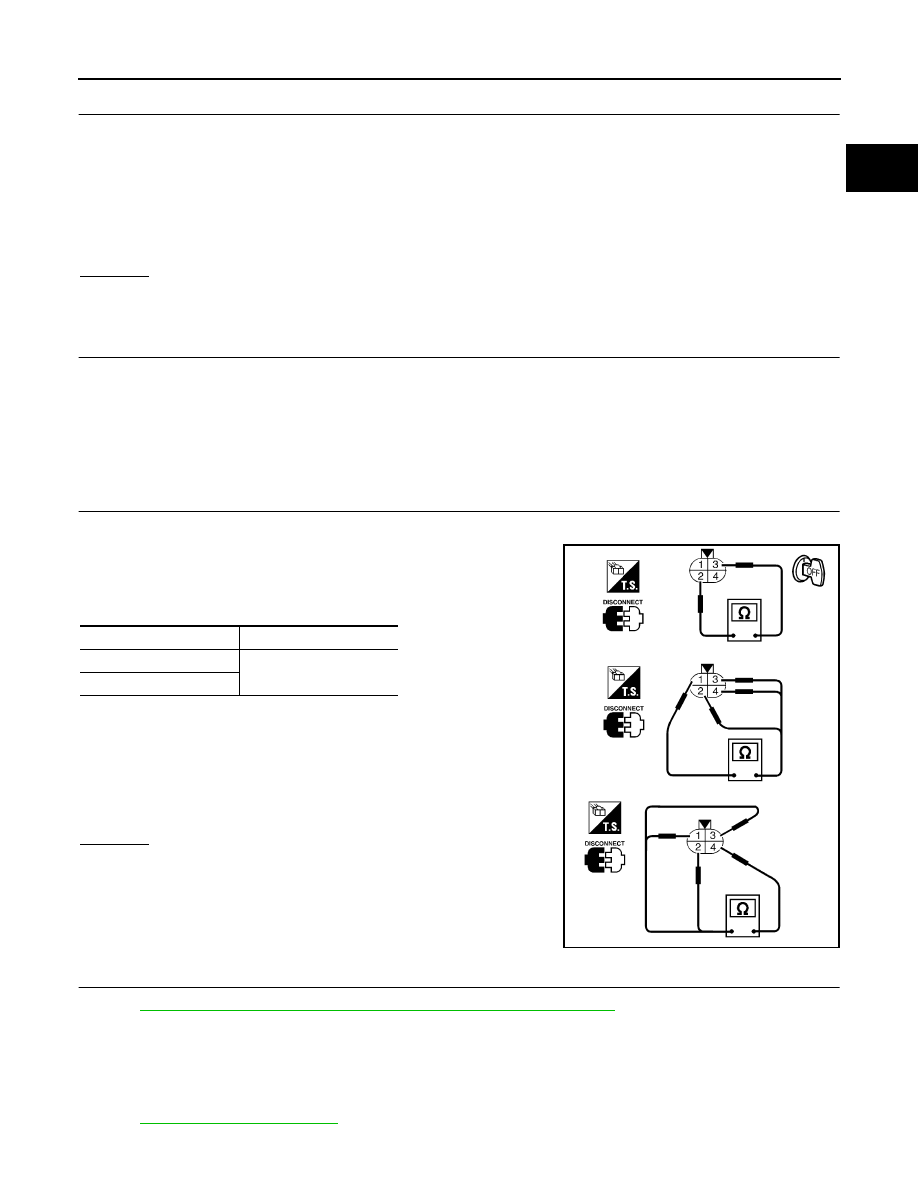

CHECK HEATED OXYGEN SENSOR 2 HEATER

Check the following.

1.

Check resistance between terminals 2 and 3.

2.

Check continuity.

CAUTION:

●

Discard any heated oxygen sensor which has been dropped

from a height of more than 0.5 m (19.7 in) onto a hard sur-

face such as a concrete floor; use a new one.

●

Before installing new oxygen sensor, clean exhaust system

threads using Oxygen Sensor Thread Cleaner tool J-43897-

18 or J-43897-12 and approved anti-seize lubricant.

OK or NG

OK

>> GO TO 6.

NG

>> Replace heated oxygen sensor 2.

6.

CHECK INTERMITTENT INCIDENT

Perform

EC-120, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT"

>> INSPECTION END.

Removal and Installation

UBS00D2A

HEATED OXYGEN SENSOR 2

Refer to

.

Continuity should exist.

Resistance

: 3.3 - 4.0

Ω [at 25°C (77°F)]

Terminal No.

Continuity

1 and 2, 3, 4

No

4 and 1, 2, 3

SEF221W