Nissan Xterra. Manual - part 347

EM-16

< PERIODIC MAINTENANCE >

[VQ40DE]

SPARK PLUG

SPARK PLUG

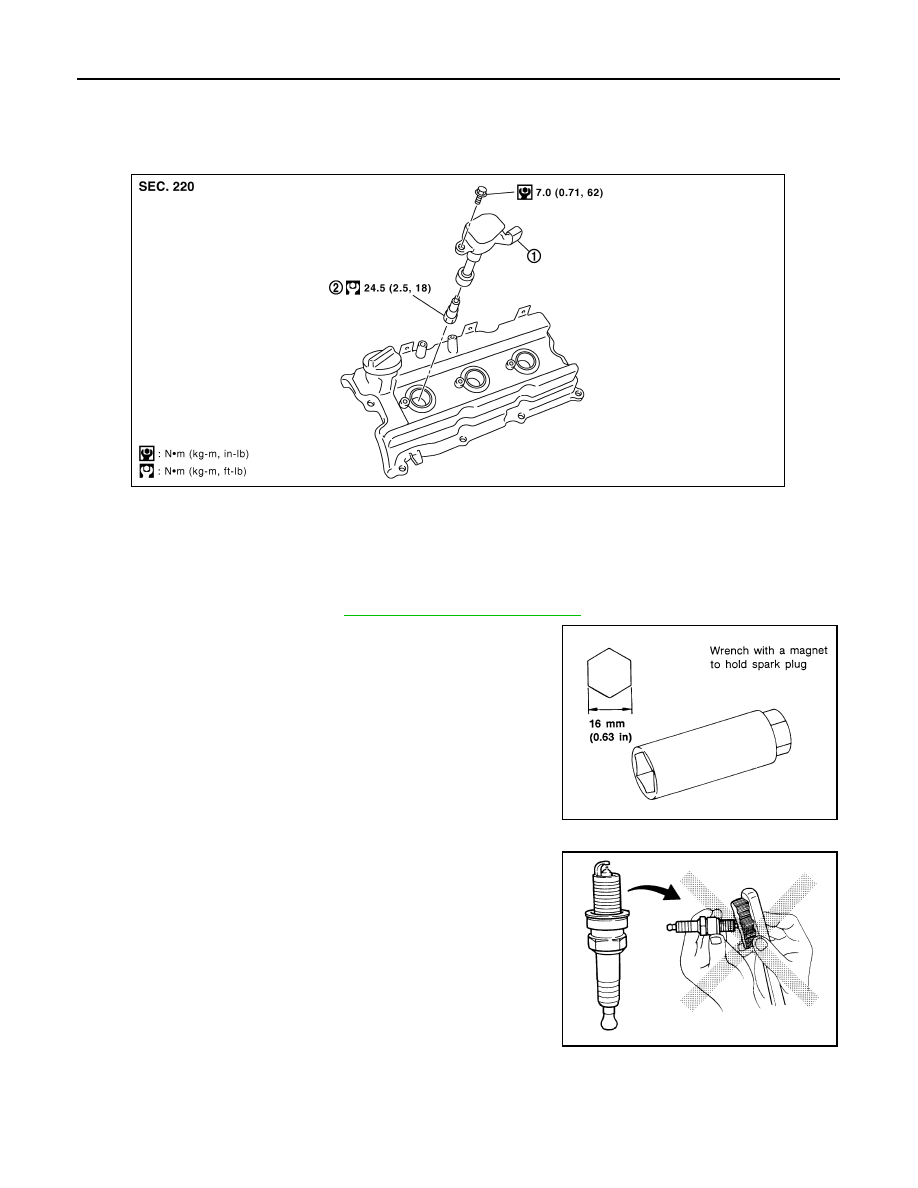

Exploded View

INFOID:0000000009484446

Removal and Installation

INFOID:0000000009484447

REMOVAL

1. Remove the ignition coil. Refer to

EM-40, "Removal and Installation"

.

2. Remove the spark plug using a suitable tool.

CAUTION:

Do not drop or shock it.

INSPECTION AFTER REMOVAL

• Do not use a wire brush for cleaning.

• If the spark plug tip is covered with carbon, spark plug cleaner may be used.

1.

Ignition coil

2.

Spark plug

PBIC2901E

SEM294A

SMA773C