Nissan Xterra. Manual - part 339

EC-482

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE]

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

Component Description

INFOID:0000000009484233

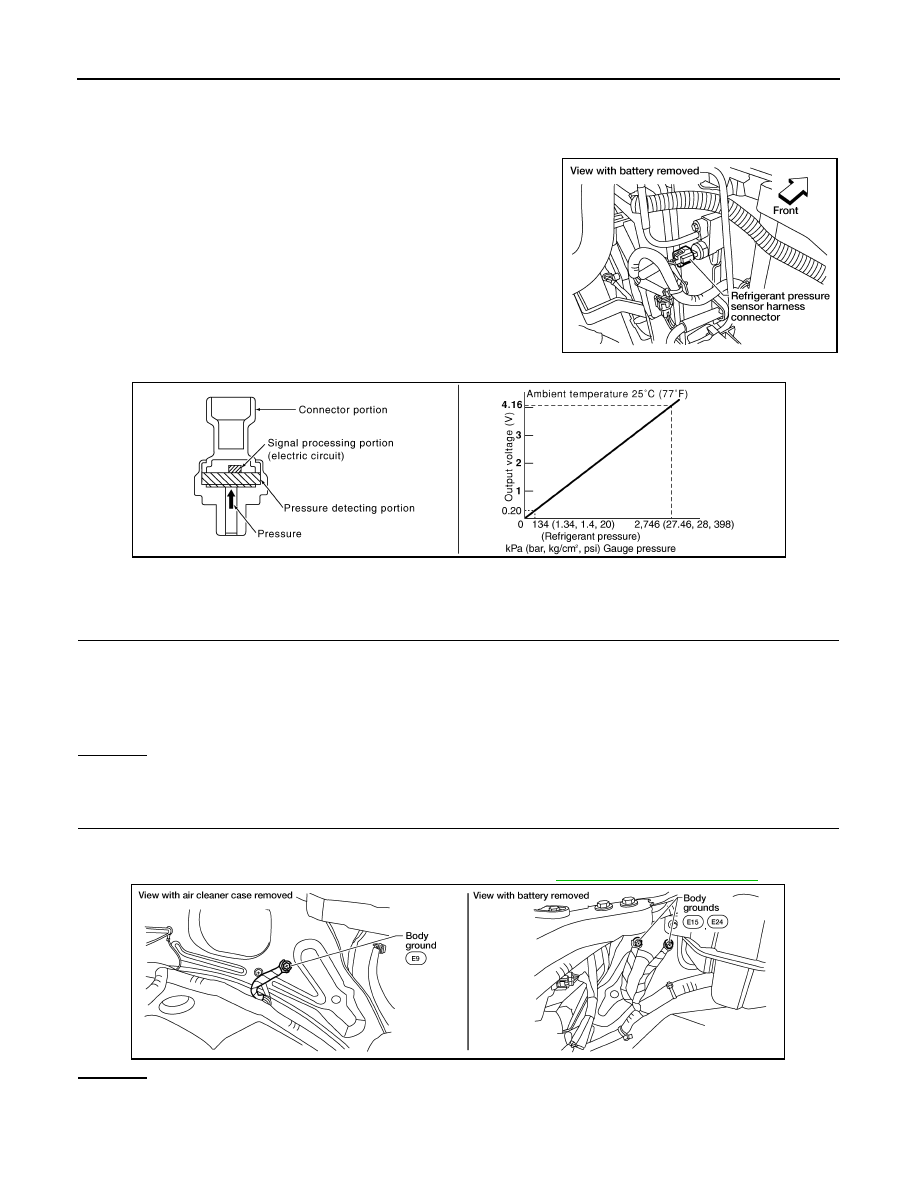

The refrigerant pressure sensor is installed at the condenser of the

air conditioner system. The sensor uses an electrostatic volume

pressure transducer to convert refrigerant pressure to voltage. The

voltage signal is sent to ECM, and ECM controls cooling fan system.

Diagnosis Procedure

INFOID:0000000009484234

1.

CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower switch ON.

3. Check voltage between ECM terminal 63 and ground with CONSULT or tester.

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 2.

2.

CHECK GROUND CONNECTIONS

1. Turn A/C switch and blower switch OFF.

2. Turn ignition switch OFF.

3. Loosen and retighten three ground screws on the body. Refer to

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace ground connections.

BBIA0564E

PBIB2657E

Voltage: 1.0 - 4.0V

BBIA0539E