Nissan Xterra. Manual - part 333

EC-458

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE]

ASCD INDICATOR

ASCD INDICATOR

Component Description

INFOID:0000000009484212

ASCD indicator lamp illuminates to indicate ASCD operation status. Lamp has two indicators, CRUISE and

SET, and is integrated in combination meter.

CRUISE indicator illuminates when MAIN switch on ASCD steering switch is turned ON to indicated that

ASCD system is ready for operation.

SET indicator illuminates when the following conditions are met.

• CRUISE indicator is illuminated.

• SET/COAST switch on ASCD steering switch is turned ON while vehicle speed is within the range of the

ASCD setting.

SET indicator remains lit during ASCD control.

for the ASCD function.

Diagnosis Procedure

INFOID:0000000009484213

1.

CHECK OVERALL FUNCTION

Check ASCD indicator under the following conditions.

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 2.

2.

CHECK DTC

Check that DTC UXXXX is not displayed.

OK or NG

OK

>> GO TO 3.

NG

>> Perform trouble diagnoses for DTC UXXXX.

3.

CHECK COMBINATION METER FUNCTION

.

OK or NG

OK

>> GO TO 4.

NG

>> Go to

MWI-5, "METER SYSTEM : System Diagram"

.

4.

CHECK INTERMITTENT INCIDENT

GI-40, "Intermittent Incident"

>> INSPECTION END

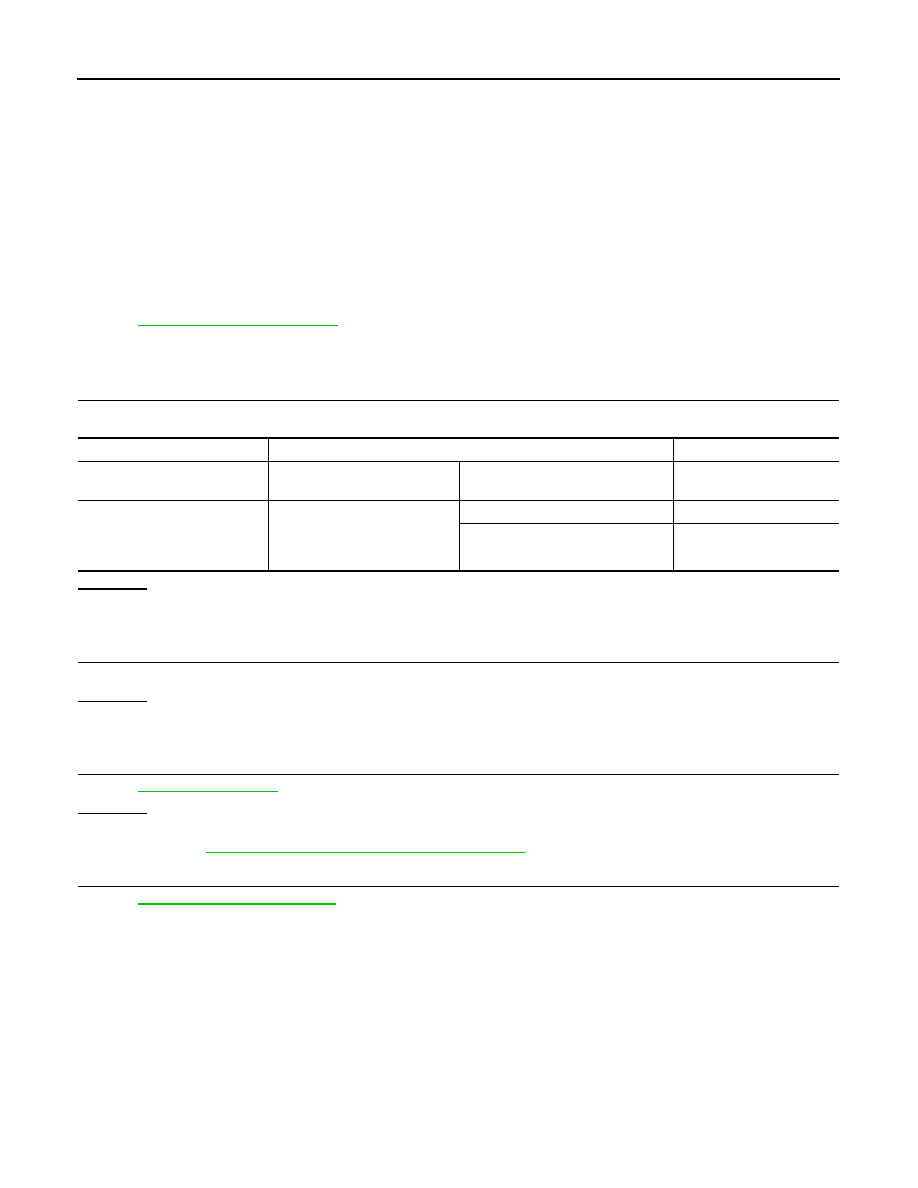

ASCD INDICATOR

CONDITION

SPECIFICATION

CRUISE LAMP

• Ignition switch: ON

MAIN switch: pressed at the 1st time

→ at the 2nd time

ON

→ OFF

SET LAMP

• MAIN switch: ON

• When vehicle speed is be-

tween 40 km/h (25 MPH) and

144 km/h (89 MPH)

ASCD: Operating

ON

ASCD: Not operating

OFF