Nissan Xterra. Manual - part 321

EC-410

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE]

P1800 VIAS CONTROL SOLENOID VALVE 1

2.

DETECT MALFUNCTIONING PART

Check the following.

• Harness for open or short between VIAS control solenoid valve and ECM

>> Repair harness or connectors.

3.

CHECK VIAS CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 39 and VIAS control solenoid valve terminal 2.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK

>> GO TO 4.

NG

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK VIAS CONTROL SOLENOID VALVE

EC-410, "Component Inspection"

OK or NG

OK

>> GO TO 5.

NG

>> Replace VIAS control solenoid valve. Refer to

.

5.

CHECK INTERMITTENT INCIDENT

GI-40, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000009484156

VIAS CONTROL SOLENOID VALVE

With CONSULT

1. Reconnect harness connectors disconnected.

2. Turn ignition switch ON.

3. Perform “VIAS S/V-1” in “ACTIVE TEST” mode.

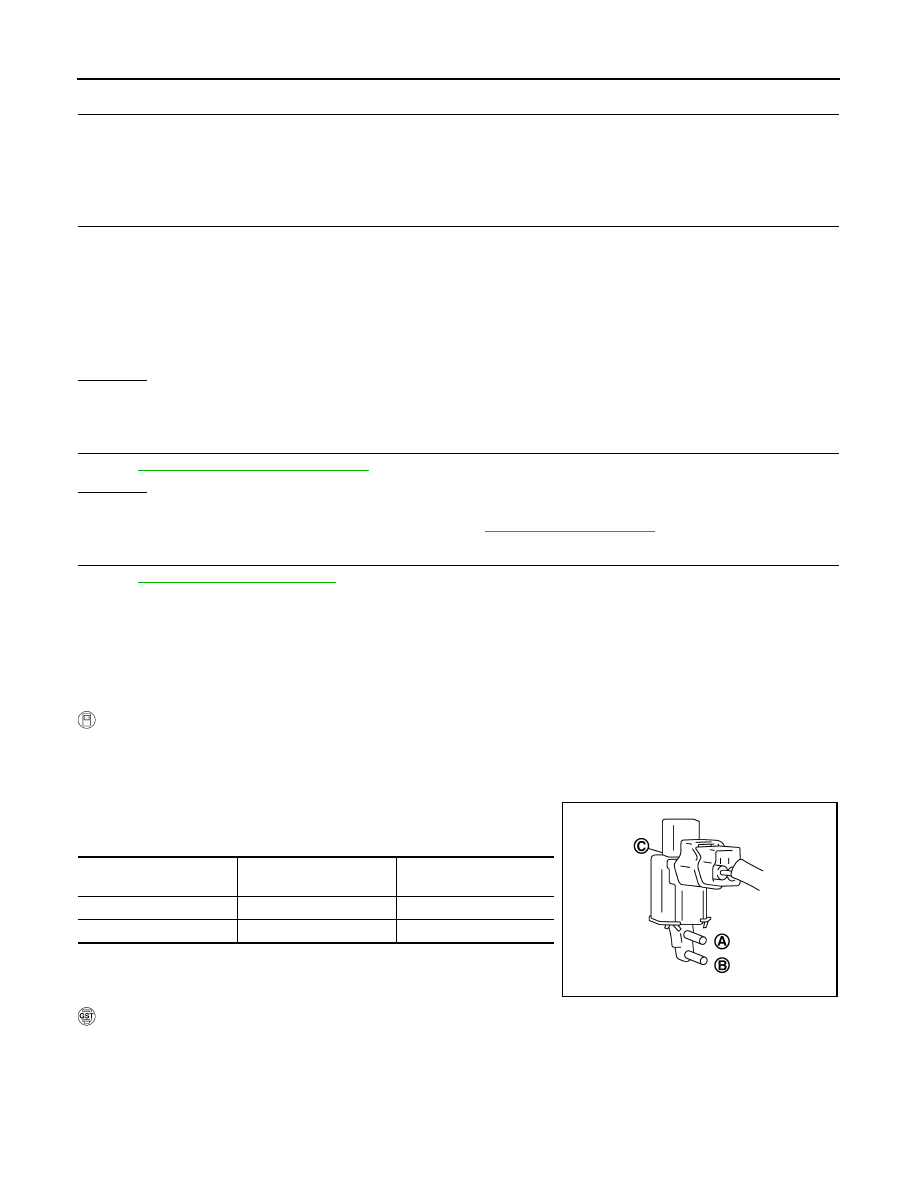

4. Check air passage continuity and operation delay time under the

following conditions.

Operation takes less than 1 second.

With GST

Continuity should exist.

Condition

VIAS SOL VALVE

Air passage continuity

between (A) and (B)

Air passage continuity

between (A) and (C)

ON

Yes

No

OFF

No

Yes

JMBIA0180ZZ