Nissan Xterra. Manual - part 303

EC-338

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE]

P0456 EVAP CONTROL SYSTEM

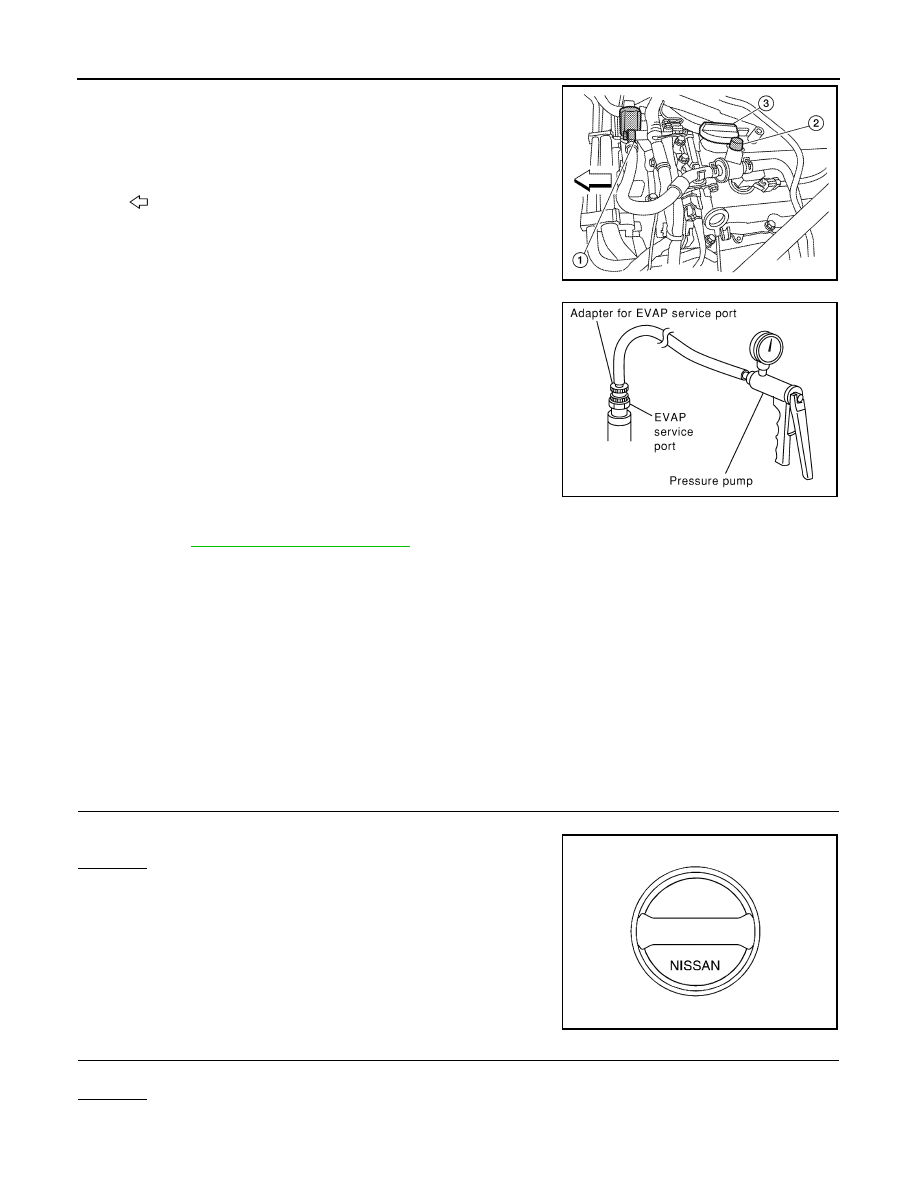

1. Attach the EVAP service port adapter securely to the EVAP ser-

vice port (2).

2. Set the pressure pump and a hose.

3. Also set a vacuum gauge via 3-way connector and a hose.

4. Turn ignition switch ON.

5. Connect GST and select Service $08.

6. Using Service $08 control the EVAP canister vent control valve

(close).

7. Apply pressure and make sure the following conditions are sat-

isfied.

Pressure to be applied: 2.7 kPa (0.028 kg/cm

2

, 0.39 psi)

Time to be waited after the pressure drawn in to the EVAP

system and the pressure to be dropped: 60 seconds and

the pressure should not be dropped more than 0.4 kPa

(0.004 kg/cm

2

, 0.06 psi).

If NG, go to

If OK, go to next step.

8. Disconnect GST.

9. Start engine and warm it up to normal operating temperature.

10. Turn ignition switch OFF and wait at least 10 seconds.

11. Turn ignition switch ON.

12. Turn ignition switch OFF and wait at least 10 seconds.

13. Restart engine and let it idle for 90 seconds.

14. Keep engine speed at 2,000 rpm for 30 seconds.

15. Turn ignition switch OFF.

NOTE:

For more information, refer to GST instruction manual.

Diagnosis Procedure

INFOID:0000000009484042

1.

CHECK FUEL FILLER CAP DESIGN

1. Turn ignition switch OFF.

2. Check for genuine NISSAN fuel filler cap design.

OK or NG

OK

>> GO TO 2.

NG

>> Replace with genuine NISSAN fuel filler cap.

2.

CHECK FUEL FILLER CAP INSTALLATION

Check that the cap is tightened properly by rotating the cap clockwise.

OK or NG

OK

>> GO TO 3.

NG

>> 1. Open fuel filler cap, then clean cap and fuel filler neck threads using air blower.

1.

EVAP canister purge volume control solenoid valve

(view with intake air duct removed)

3.

Oil filler cap

:Front

AWBIA0687ZZ

SEF462UI

SEF915U