Nissan Xterra. Manual - part 259

EC-162

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE]

P0037, P0038, P0057, P0058 HO2S2 HEATER

4. Turn ignition switch ON.

5. Turn ignition switch OFF and wait at least 10 seconds.

6. Start the engine and keep the engine speed between 3,500 rpm and 4,000 rpm for at least 1 minute under

no load.

7. Let engine idle for 1 minute.

8. Check 1st trip DTC.

9. If 1st trip DTC is detected, go to

WITH GST

Follow the procedure “WITH CONSULT” above.

Diagnosis Procedure

INFOID:0000000009483846

1.

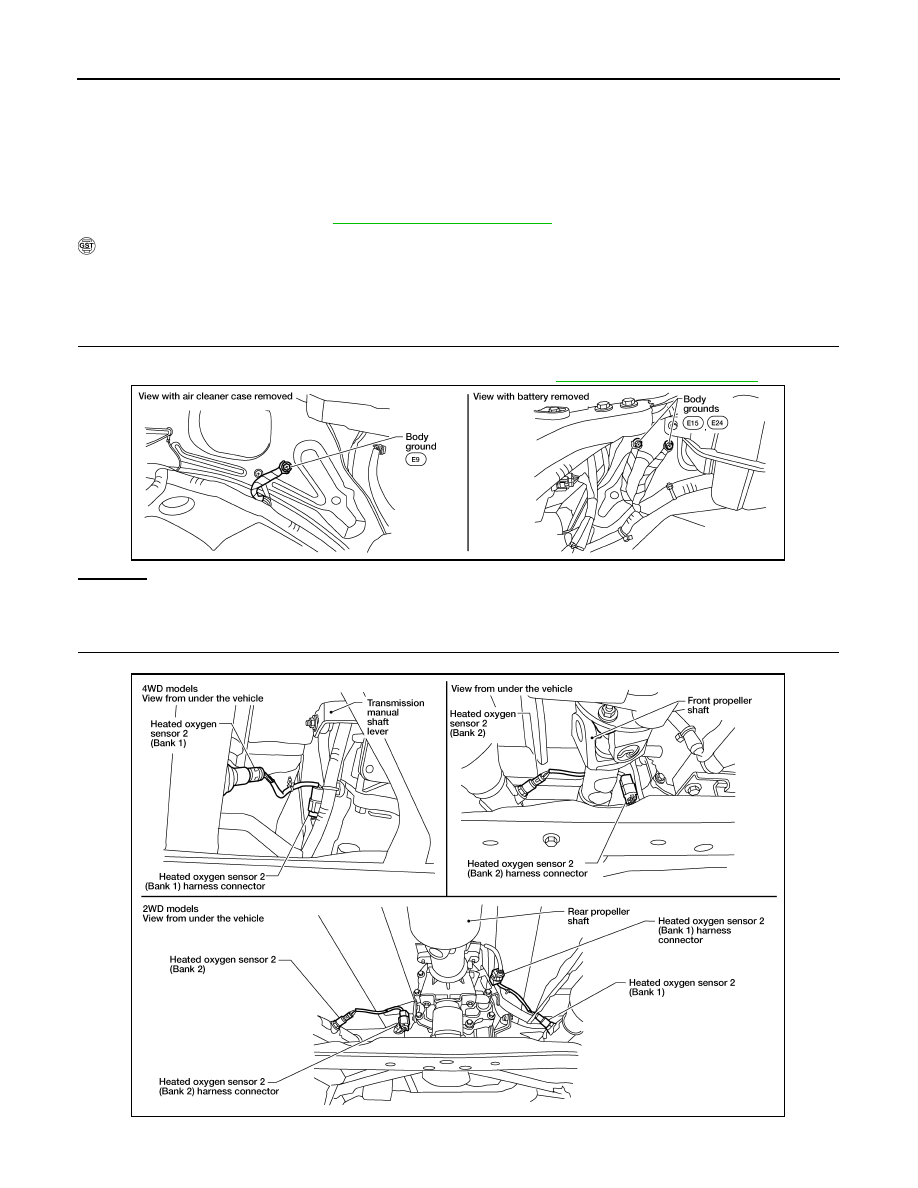

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body. Refer to

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace ground connections.

2.

CHECK HO2S2 POWER SUPPLY CIRCUIT

1. Disconnect heated oxygen sensor 2 harness connector.

2. Turn ignition switch ON.

BBIA0539E

BBIA0540E