Nissan Xterra. Manual - part 249

EC-122

< BASIC INSPECTION >

[VQ40DE]

INSPECTION AND ADJUSTMENT

2. Perform initialization of NVIS (NATS) system and registration of all NVIS (NATS) ignition key IDs. Refer to

SEC-7, "ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement"

.

>> GO TO 4.

19.

INSPECTION END

Did you replace the ECM, referring this Basic Inspection Procedure?

Yes or No

Yes

>> 1. Perform

2. INSPECTION END

No

>> INSPECTION END

Idle Speed and Ignition Timing Check

INFOID:0000000009483808

IDLE SPEED

With CONSULT

Check idle speed in “DATA MONITOR” mode with CONSULT.

With GST

Check idle speed with GST.

IGNITION TIMING

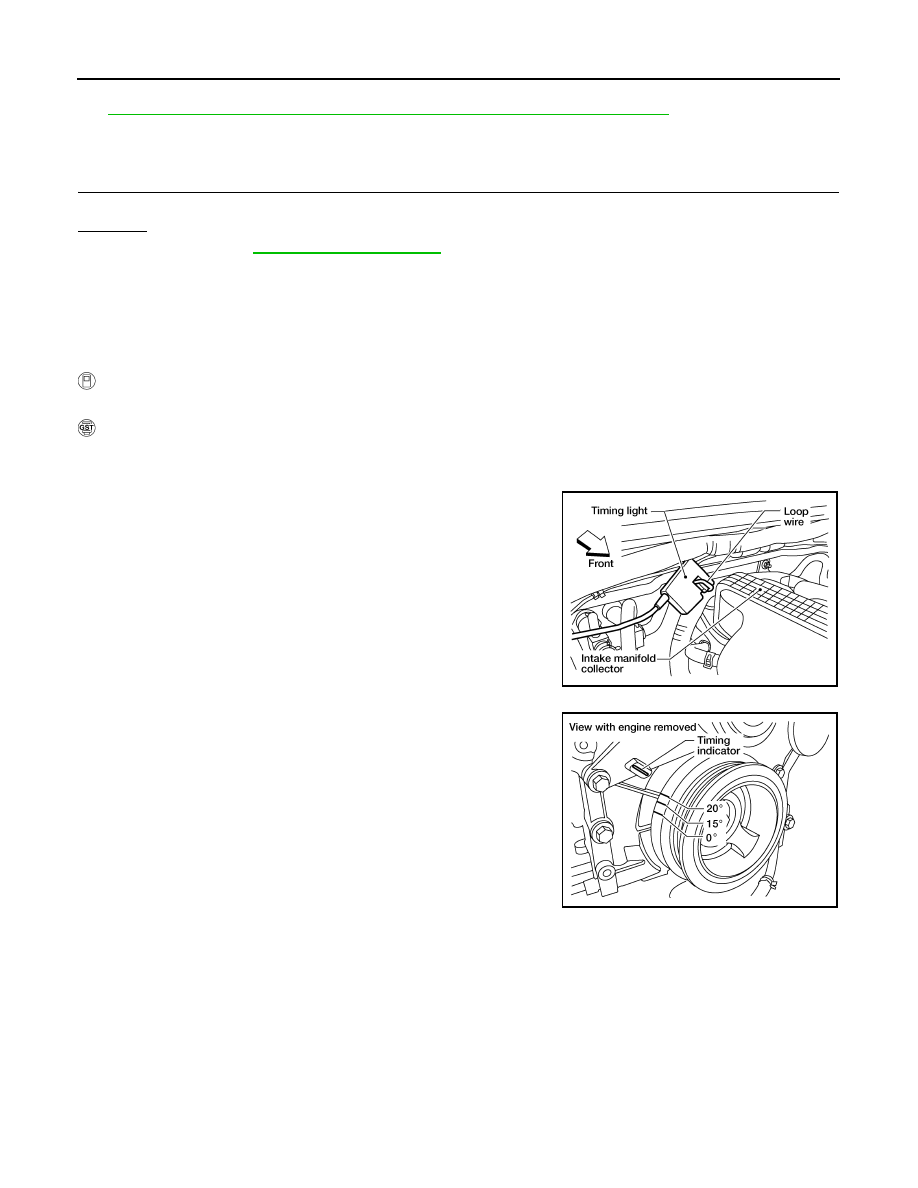

1. Attach timing light to loop wire as shown.

2. Check ignition timing.

Additional Service When Replacing ECM

INFOID:0000000009483809

DESCRIPTION

When replacing ECM, the following procedure must be performed. (For details, refer to WORK PROCE-

DURE.)

PROGRAMMING OPERATION

NOTE:

After replacing with a blank ECM, programming is required to write ECM information. Be sure to follow the pro-

cedure to perform the programming.

WORK PROCEDURE

BBIA0530E

BBIA0531E