Nissan March K13. Manual - part 583

B2603 SHIFT POSITION

SEC-71

< DTC/CIRCUIT DIAGNOSIS >

[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

M

A

B

SEC

N

O

P

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> Replace transaxle assembly. Refer to TM.

7.

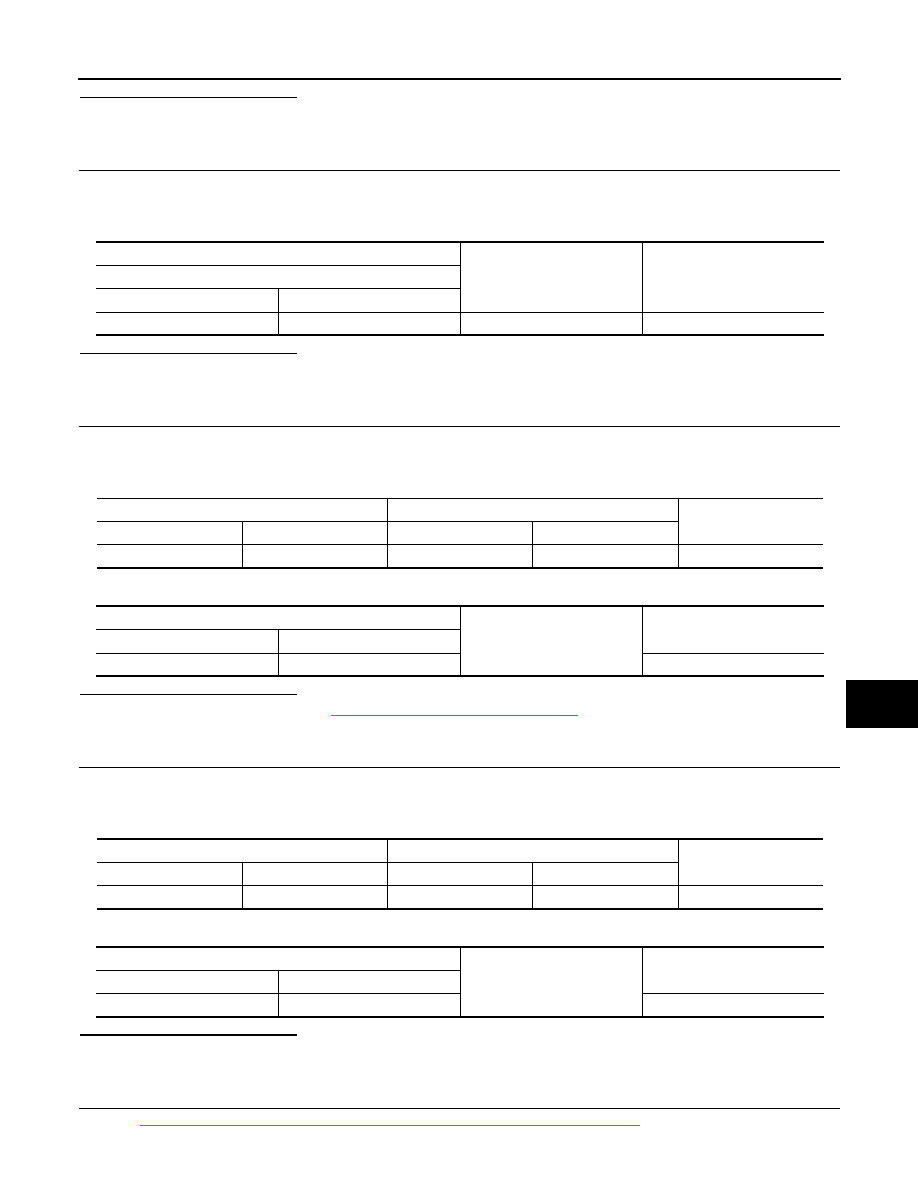

CHECK A/T SHIFT SELECTOR POWER SUPPLY

1.

Turn ignition switch OFF.

2.

Disconnect A/T shift selector (detention switch) connector.

3.

Check voltage between A/T shift selector (detention switch) harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> GO TO 8.

8.

CHECK A/T SHIFT SELECTOR POWER SUPPLY CIRCUIT

1.

Disconnect BCM connector.

2.

Check continuity between A/T shift selector (detention switch) harness connector and BCM harness con-

nector.

3.

Check continuity between A/T shift selector (detention switch) harness connector and ground.

Is the inspection result normal?

YES

>> Replace BCM. Refer to

BCS-57, "Removal and Installation"

NO

>> Repair or replace harness.

9.

CHECK A/T SHIFT SELECTOR CIRCUIT

1.

Disconnect BCM connector and IPDM E/R connector.

2.

Check continuity between A/T shift selector (detention switch) harness connector and BCM harness con-

nector.

3.

Check continuity between A/T shift selector (detention switch) harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> Repair or replace harness.

10.

CHECK A/T SHIFT SELECTOR (DETENTION SWITCH)

SEC-72, "Component Inspection [A/T Shift Selector (Detention Switch)]"

(+)

(–)

Voltage (V)

(Approx.)

A/T shift selector (detention switch)

Connector

Terminal

M58

7

Ground

12

A/T shift selector (detention switch)

BCM

Continuity

Connector

Terminal

Connector

Terminal

M58

7

M71

104

Existed

A/T shift selector (detention switch)

Ground

Continuity

Connector

Terminal

M58

7

Not existed

A/T shift selector (detention switch)

BCM

Continuity

Connector

Terminal

Connector

Terminal

M58

8

M68

37

Existed

A/T shift selector (detention switch)

Ground

Continuity

Connector

Terminal

M58

8

Not existed