Nissan March K13. Manual - part 492

PCS-50

< DTC/CIRCUIT DIAGNOSIS >

[IPDM E/R (WITHOUT I-KEY)]

B2099 IGNITION RELAY OFF STUCK

B2099 IGNITION RELAY OFF STUCK

Description

INFOID:0000000006025269

The ignition relay integrated in IPDM E/R is operated with ignition switch ON signal from the ignition switch.

DTC Logic

INFOID:0000000006025262

DTC DETECTION LOGIC

NOTE:

When IPDM E/R power supply voltage is low (Approx. 7 - 8 V for about 1 second), the “DTC: B2099” may be detected.

Diagnosis Procedure

INFOID:0000000006025263

1.

PERFORM SELF DIAGNOSIS

1.

Turn the ignition switch ON.

2.

Erase “Self Diagnostic Result”.

3.

Turn the ignition switch OFF.

4.

Turn the ignition switch ON. Check “Self Diagnostic Result” again.

Is DTC “B2099” displayed?

YES

>> Replace IPDM E/R. Refer to

PCS-28, "Removal and Installation"

NO

>> Refer to

GI-33, "Intermittent Incident"

.

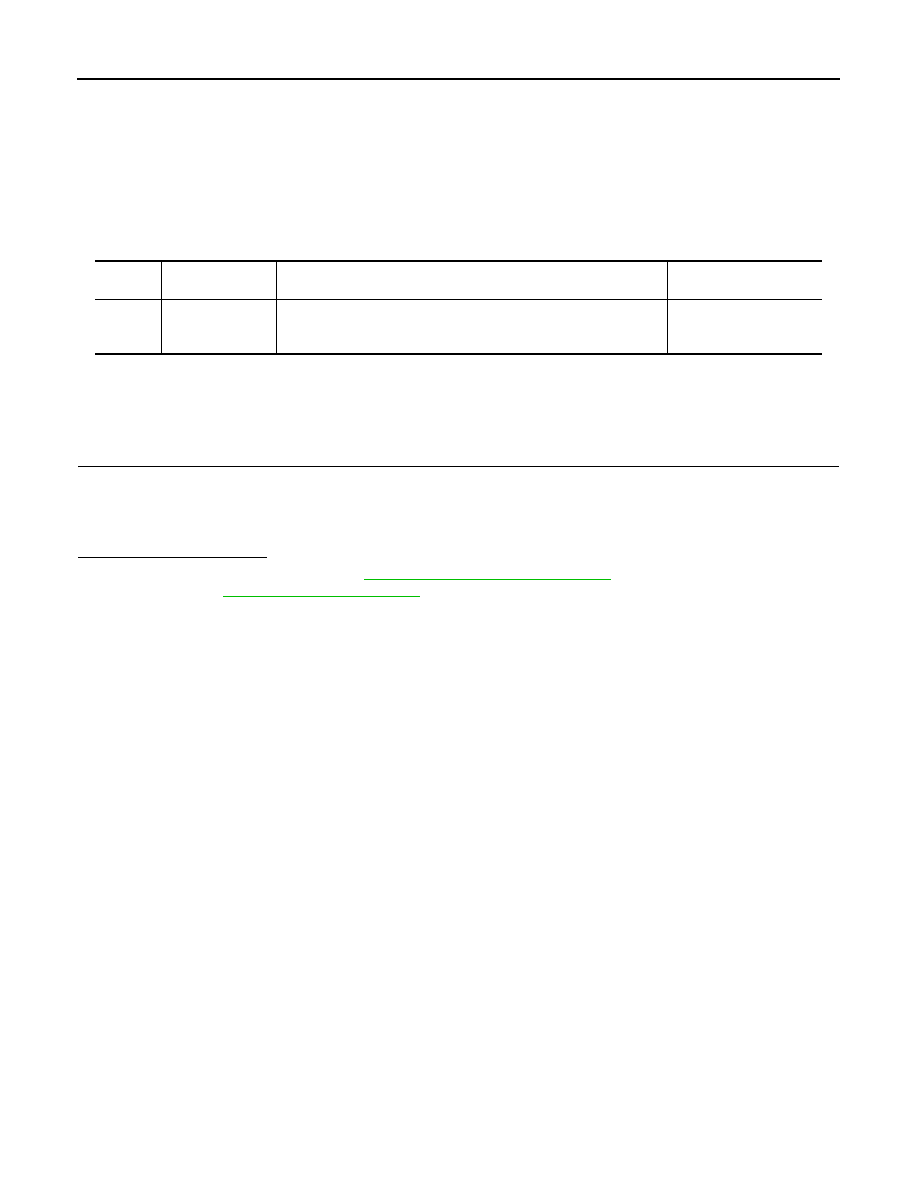

DTC

CONSULT-III dis-

play description

DTC Detection Condition

Possible causes

B2099

IGN RELAY OFF

The ignition relay OFF is detected for 1 second at ignition switch ON

(CPU monitors the status at the contact and excitation coil circuits of

the ignition relay inside it)

Ignition relay malfunction