Nissan March K13. Manual - part 312

EXL-74

< DTC/CIRCUIT DIAGNOSIS >

TAIL LAMP CIRCUIT

TAIL LAMP CIRCUIT

Component Function Check

INFOID:0000000005912432

NOTE:

Check the parking lamp circuit if the parking lamp and the tail lamp are not turned ON.

1.

CHECK TAIL LAMP OPERATION

IPDM E/R AUTO ACTIVE TEST

1.

Activate IPDM E/R auto active test. Refer to

PCS-11, "Diagnosis Description"

.

2.

Check that the tail lamp is turned ON.

CONSULT-III ACTIVE TEST

1.

Select “EXTERNAL LAMPS” of IPDM E/R active test item.

2.

With operating the test items, check that the tail lamp is turned ON.

Is the tail lamp turned ON?

YES

>> Tail lamp circuit is normal.

NO

>> Refer to

.

Diagnosis Procedure

INFOID:0000000005912433

1.

CHECK TAIL LAMP BULB

Check the applicable lamp bulb.

Is the measurement value normal?

YES

>> GO TO 2.

NO

>> Replace the bulb.

2.

CHECK TAIL LAMP OPEN CIRCUIT

1.

Turn the ignition switch OFF.

2.

Disconnect IPDM E/R connector.

3.

Check continuity between the IPDM E/R harness connector and the rear combination lamp harness con-

nector.

Does continuity exist?

YES

>> GO TO 3.

NO

>> Repair the harnesses or connectors.

3.

CHECK TAIL LAMP GROUND OPEN CIRCUIT

Check continuity between the rear combination lamp harness connector and the ground.

Does continuity exist?

YES

>> Replace the rear combination lamp.

NO

>> Repair the harnesses or connectors.

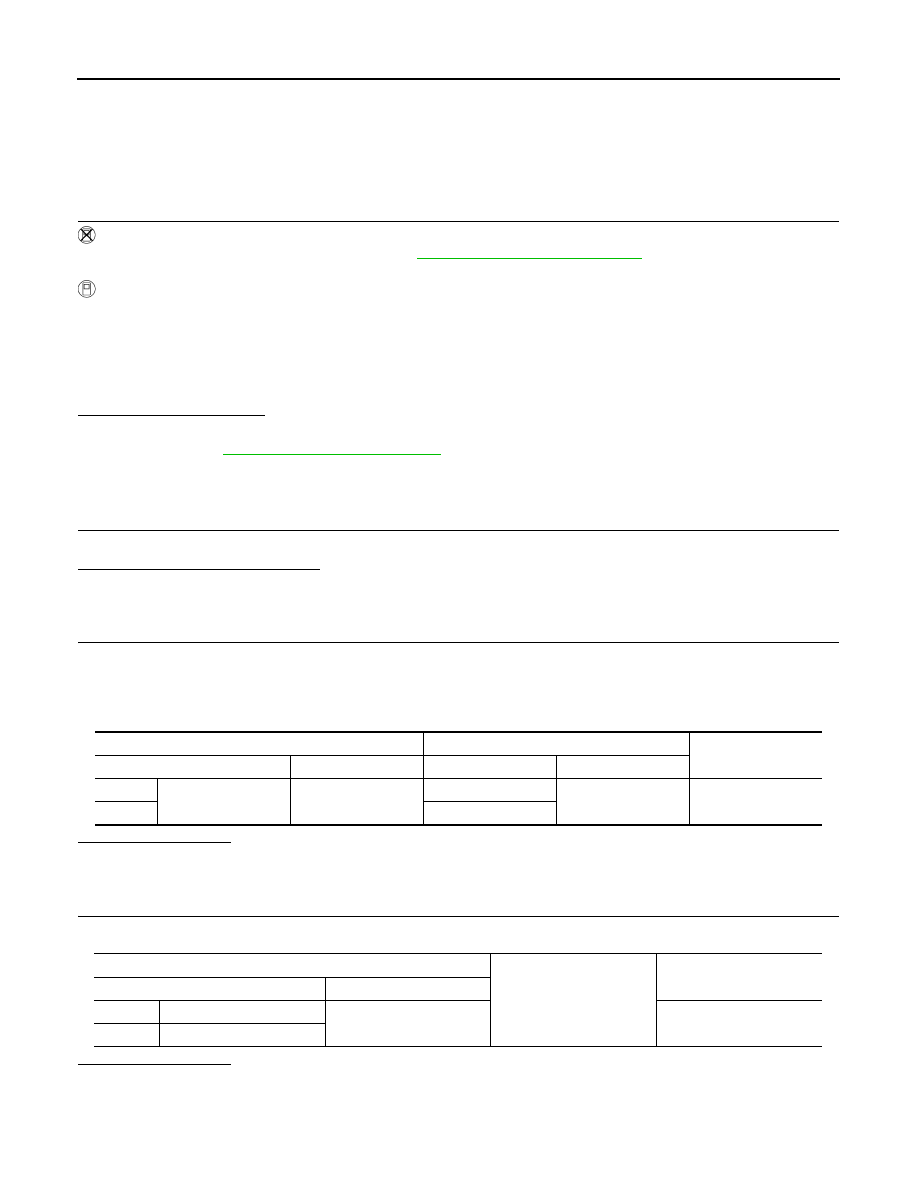

TAIL

: Tail lamp ON

Off

: Tail lamp OFF

IPDM E/R

Rear combination lamp

Continuity

Connector

Terminal

Connector

Terminal

RH

E14

59

B59

6

Existed

LH

B80

Rear combination lamp

Ground

Continuity

Connector

Terminal

RH

B59

3

Existed

LH

B80