Nissan March K13. Manual - part 242

P0335 CKP SENSOR (POS)

EC-429

< DTC/CIRCUIT DIAGNOSIS >

[HR12DE (TYPE 2)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace crankshaft position sensor (POS).

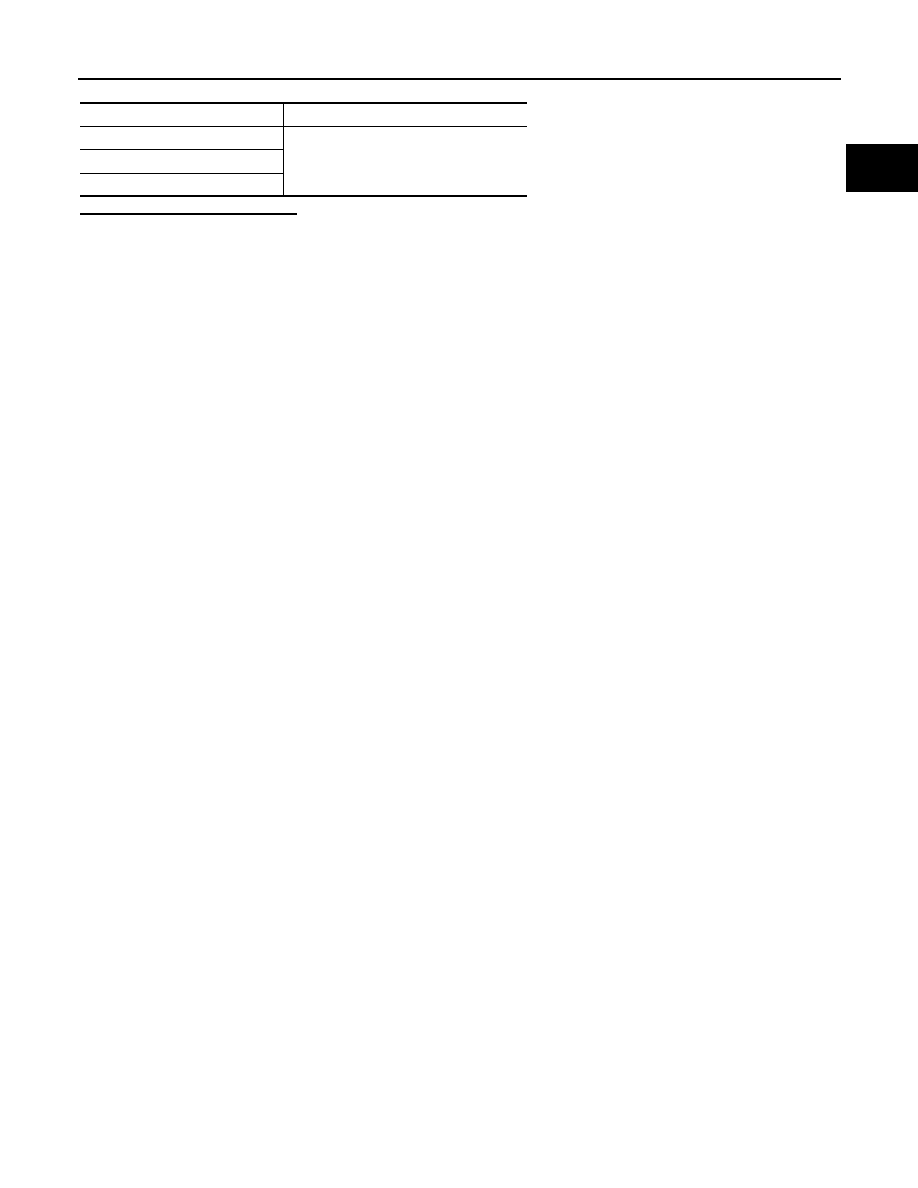

Terminals (Polarity)

Resistance [at 25

°

C (77

°

F)]

1 (+) - 2 (

−

)

Except 0 or

∞

Ω

1 (+) - 3 (

−

)

2 (+) - 3 (

−

)