Nissan March K13. Manual - part 137

APPLICATION NOTICE

EC-9

< HOW TO USE THIS MANUAL >

[HR12DE (TYPE 1)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

HOW TO USE THIS MANUAL

APPLICATION NOTICE

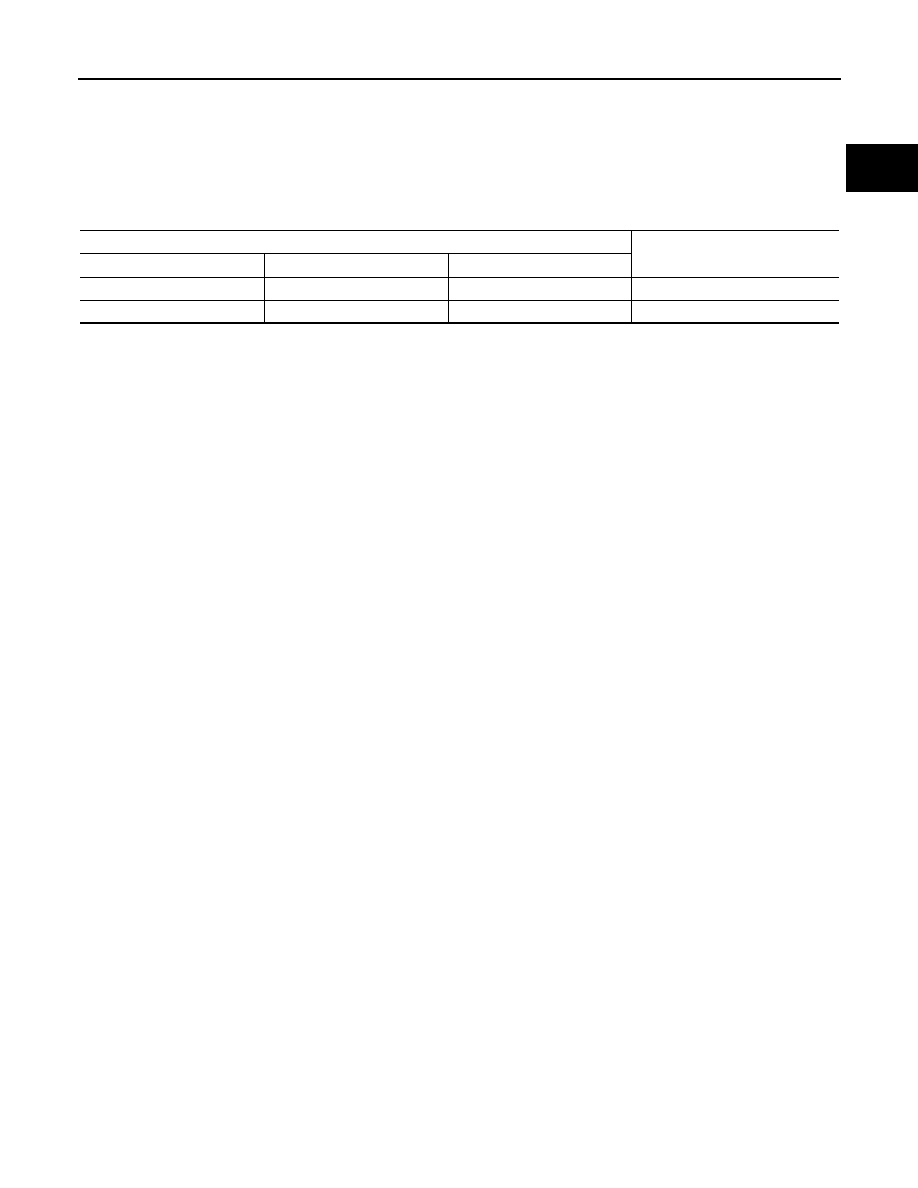

How to Check Vehicle Type

INFOID:0000000006022900

Check the vehicle type to confirm the service information in EC section.

NOTE:

• L-jetronic is a fuel injection control method that the mass air flow sensor mounted on the air cleaner case

directly measures air volume taken into the engine (cylinder) and determines the fundamental fuel injection

amount.

• D-jetronic is a fuel injection control method to calculate air volume taken into the engine (cylinder) and deter-

mine the fundamental fuel injection amount, based on a throttle angle and an intake air pressure calculated

by the manifold absolute pressure sensor mounted on the intake manifold.

Vehicle type

Service information

Destination

Transmission

Engine control

For Thailand

M/T

L-jetronic

HR12DE (TYPE 1)

Except for Thailand

A/T, M/T

D-jetronic

HR12DE (TYPE 2)