Nissan GT-R (2007-2014 year). POWER CONTROL SYSTEM / POWER WINDOW CONTROL SYSTEM. Service Manual - part 2

PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-17

< REMOVAL AND INSTALLATION >

[IPDM E/R]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

REMOVAL AND INSTALLATION

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

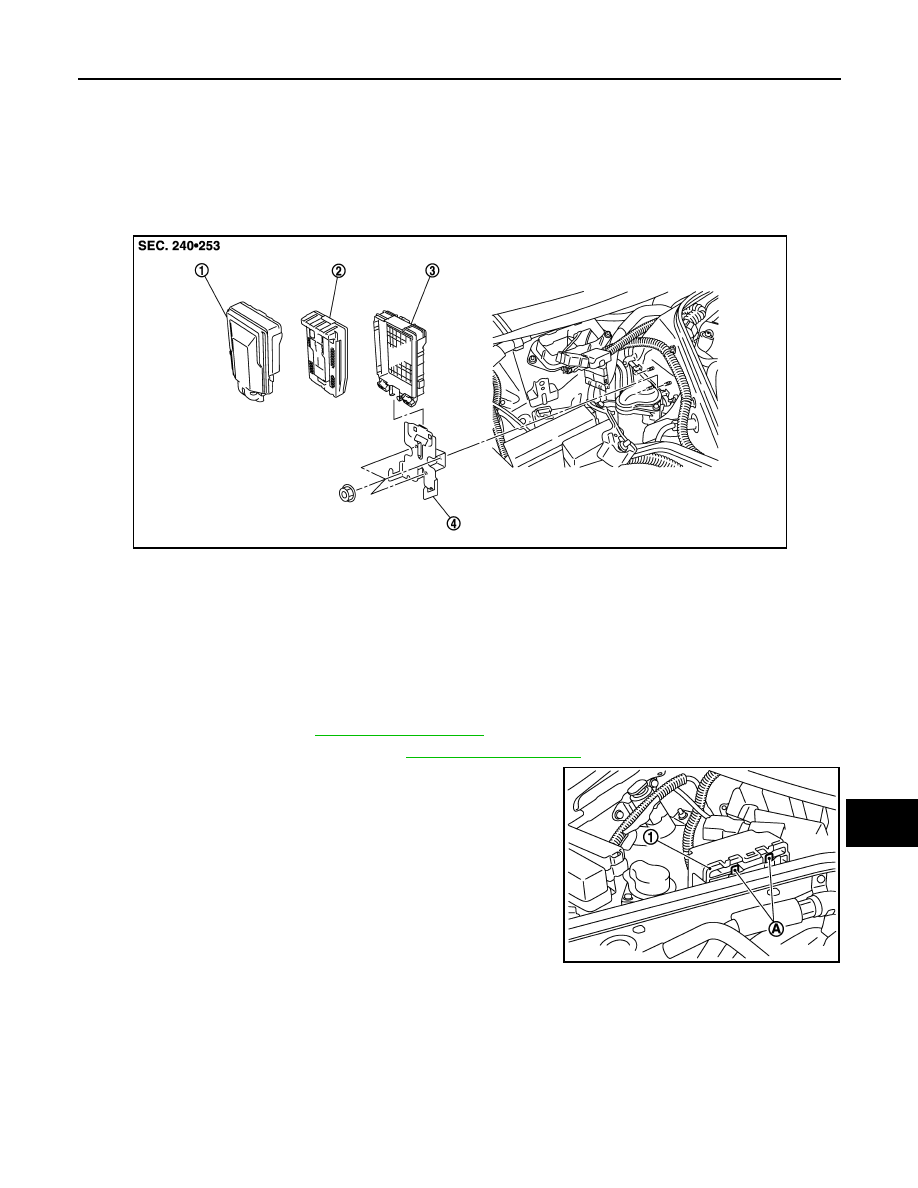

Exploded View

INFOID:0000000009163870

Removal and Installation

INFOID:0000000009163871

CAUTION:

IPDM E/R integrated relays are not serviceable parts, and must not be removed from the unit.

REMOVAL

1.

Remove the battery. Refer to

2.

Remove the cowl top cover (RH). Refer to

.

3.

Pull up the IPDM E/R assembly while pressing the pawls (A) on

the back of the IPDM E/R cover B (1).

1.

IPDM E/R cover A

2.

IPDM E/R

3.

IPDM E/R cover B

4.

Bracket

NNMIA0052ZZ

NNMIA0053ZZ

2014 GT-R