Nissan GT-R (2007-2014 year). DRIVELINE / DRIVE MODE SYSTEM. Service Manual - part 2

SERVICE DATA AND SPECIFICATIONS (SDS)

DLN-17

< SERVICE DATA AND SPECIFICATIONS (SDS)

[MAIN PROPELLER SHAFT: 2F71A-VL101]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

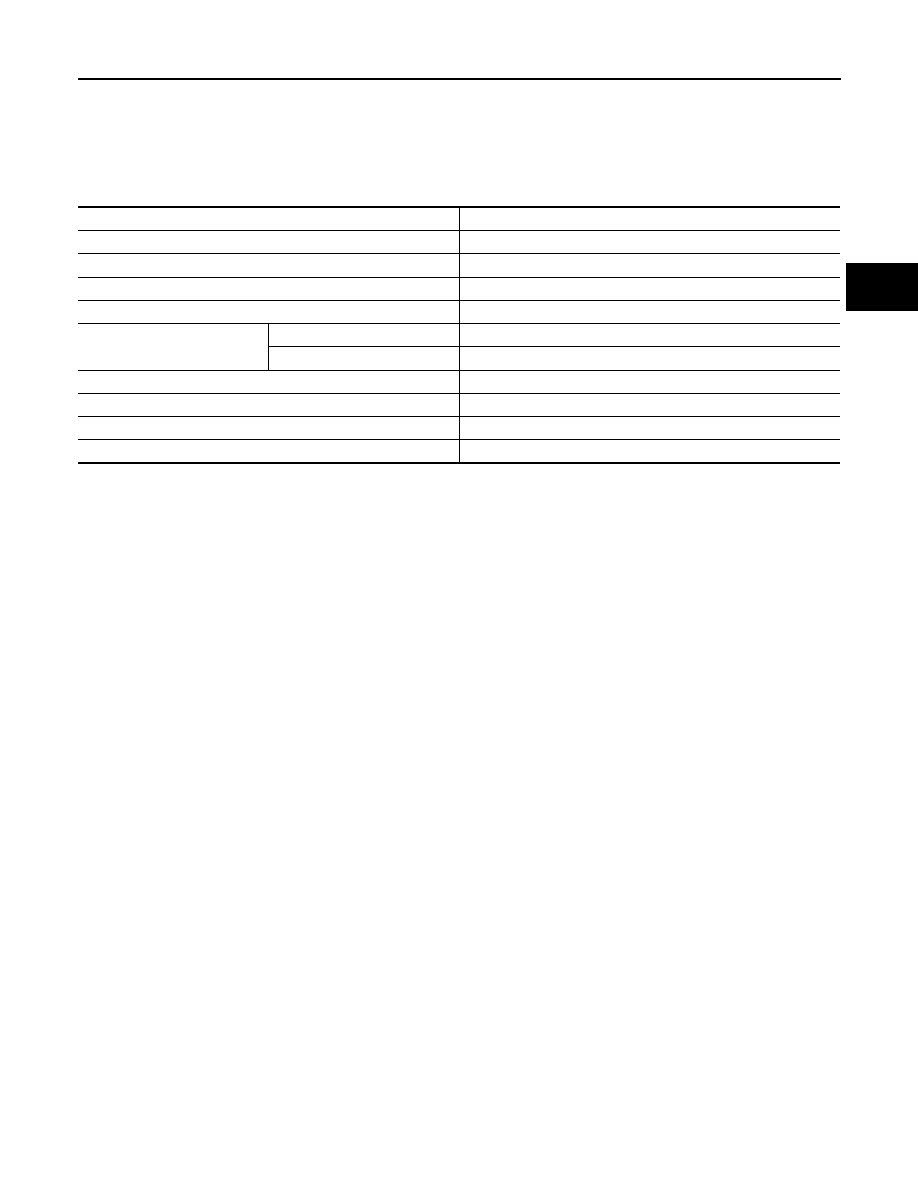

General Specifications

INFOID:0000000009162078

Drive type

AWD

Engine

VR38DETT

Transmission

GR6Z30A

Propeller shaft model

2F71A-VL101

Number of joints

2

Type of journal bearings

(Non-disassembly type)

1st joint

Cardan type

2nd joint

CVJ type

Coupling method with engine

Flange type

Coupling method with transmission

Rebro joint type

Shaft length (Spider to spider)

1117 mm (43.98 in)

Shaft outer diameter

71 mm (2.80 in)

Revision: 2012 November

2014 GT-R