содержание .. 98 99 100 101 ..

Nissan GT-R. Manual - part 100

DIAGNOSIS SYSTEM (IPDM E/R)

EXL-17

< SYSTEM DESCRIPTION >

[XENON TYPE]

C

D

E

F

G

H

I

J

K

M

A

B

EXL

N

O

P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis Description

INFOID:0000000009160314

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following systems to check their operation.

• Front wiper (LO, HI)

• Parking lamps

• License plate lamps

• Side marker lamps

• Tail lamps

• Headlamps (LO, HI)

• A/C compressor (magnet clutch)

• Cooling fan (cooling fan control module)

Operation Procedure

1.

Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2.

Turn the ignition switch OFF.

3.

Turn the ignition switch ON, and within 20 seconds, press the driver door switch 10 times. Then turn the

ignition switch OFF.

CAUTION:

Close passenger door.

4.

Turn the ignition switch ON within 10 seconds. After that the horn sounds once and the auto active test

starts.

5.

After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway through test, turn the ignition switch OFF.

CAUTION:

• If auto active test mode cannot be actuated, check door switch system. Refer to

.

• Do not start the engine.

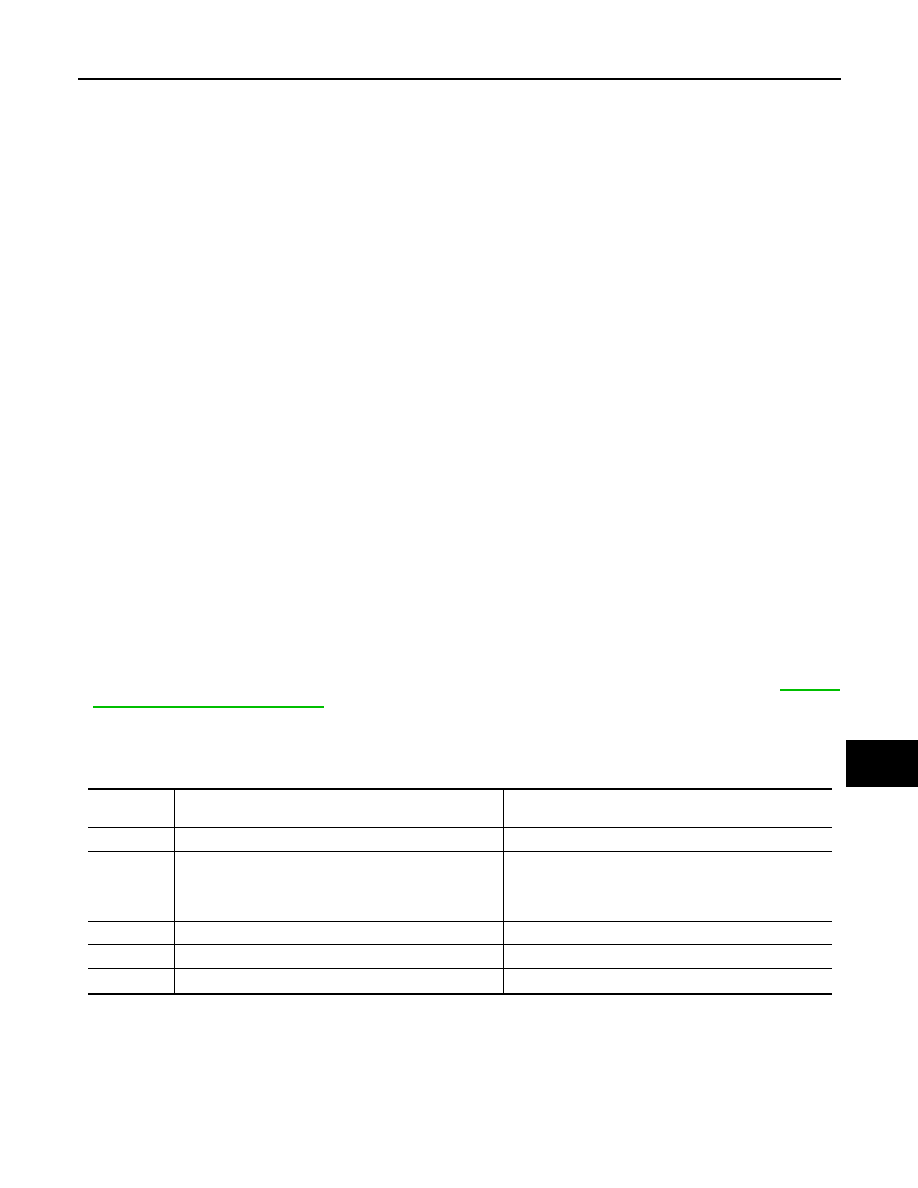

Inspection in Auto Active Test Mode

When auto active test mode is actuated, the following 5 steps are repeated 3 times.

*: Outputs duty ratio of 50% for 5 seconds

→

duty ratio of 100% for 5 seconds on the cooling fan control module.

Operation

sequence

Inspection location

Operation

1

Front wiper

LO for 5 seconds

→

HI for 5 seconds

2

• Parking lamps

• License plate lamps

• Side marker lamps

• Tail lamps

10 seconds

3

Headlamps

LO

⇔

HI 5 times

4

A/C compressor (magnet clutch)

ON

⇔

OFF 5 times

5

*

Cooling fan

MID for 5 seconds

→

HI for 5 seconds