содержание .. 76 77 78 79 ..

Nissan GT-R. Manual - part 78

DLN-16

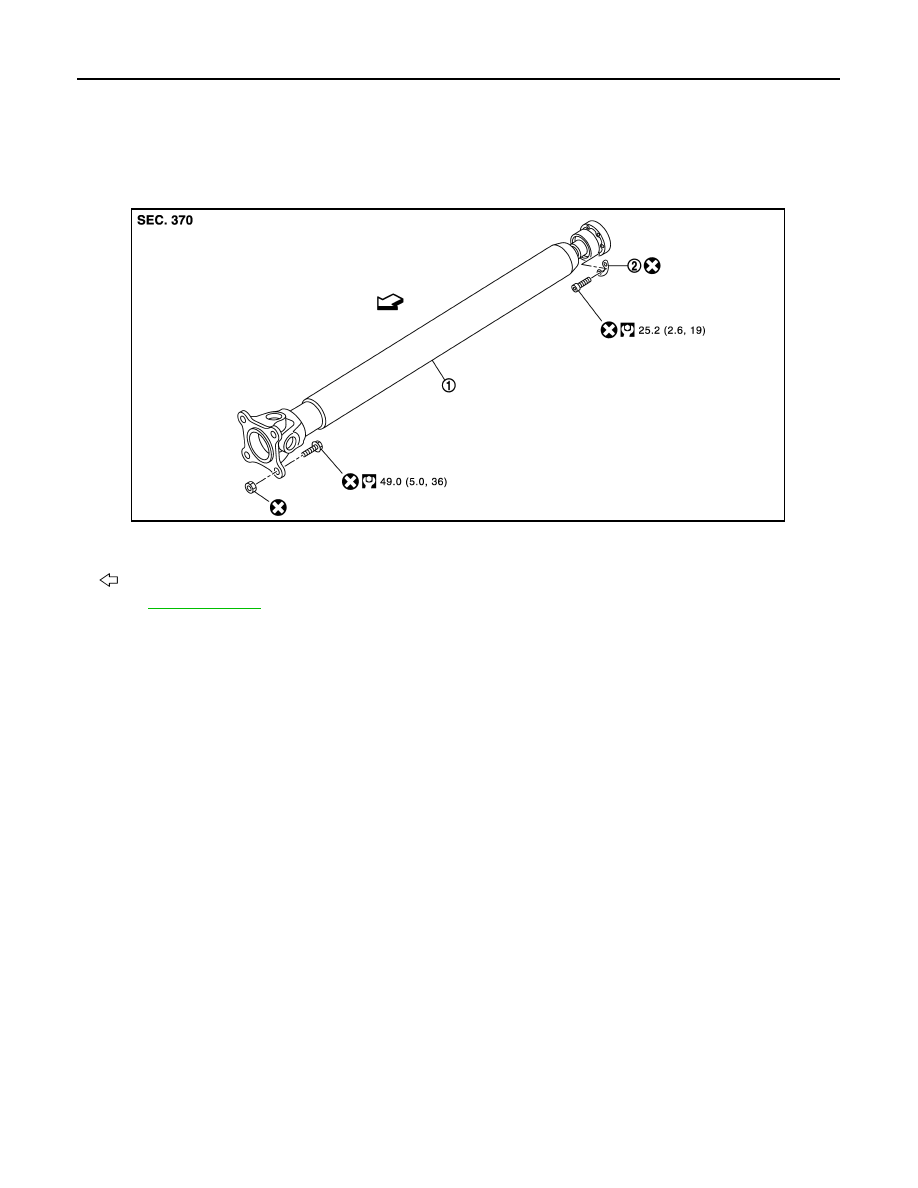

< REMOVAL AND INSTALLATION >

[MAIN PROPELLER SHAFT: 2F71A-VL101]

MAIN PROPELLER SHAFT

REMOVAL AND INSTALLATION

MAIN PROPELLER SHAFT

Exploded View

INFOID:0000000009162075

1.

Main propeller shaft assembly

2.

Plain washer

: The front of vehicle

Refer to

in GI section for the symbols shown in the figure.

NNDID0013GB