Nissan Pathfinder (2012 year). Manual - part 462

LU-34

< UNIT DISASSEMBLY AND ASSEMBLY >

[VK56DE]

OIL PUMP

UNIT DISASSEMBLY AND ASSEMBLY

OIL PUMP

Disassembly and Assembly

INFOID:0000000007357897

DISASSEMBLY

1. Remove oil pump cover.

2. Remove inner rotor and outer rotor from oil pump body.

3. Remove the regulator valve plug, regulator valve spring and regulator valve.

INSPECTION AFTER DISASSEMBLY

Clearance of Oil Pump Parts

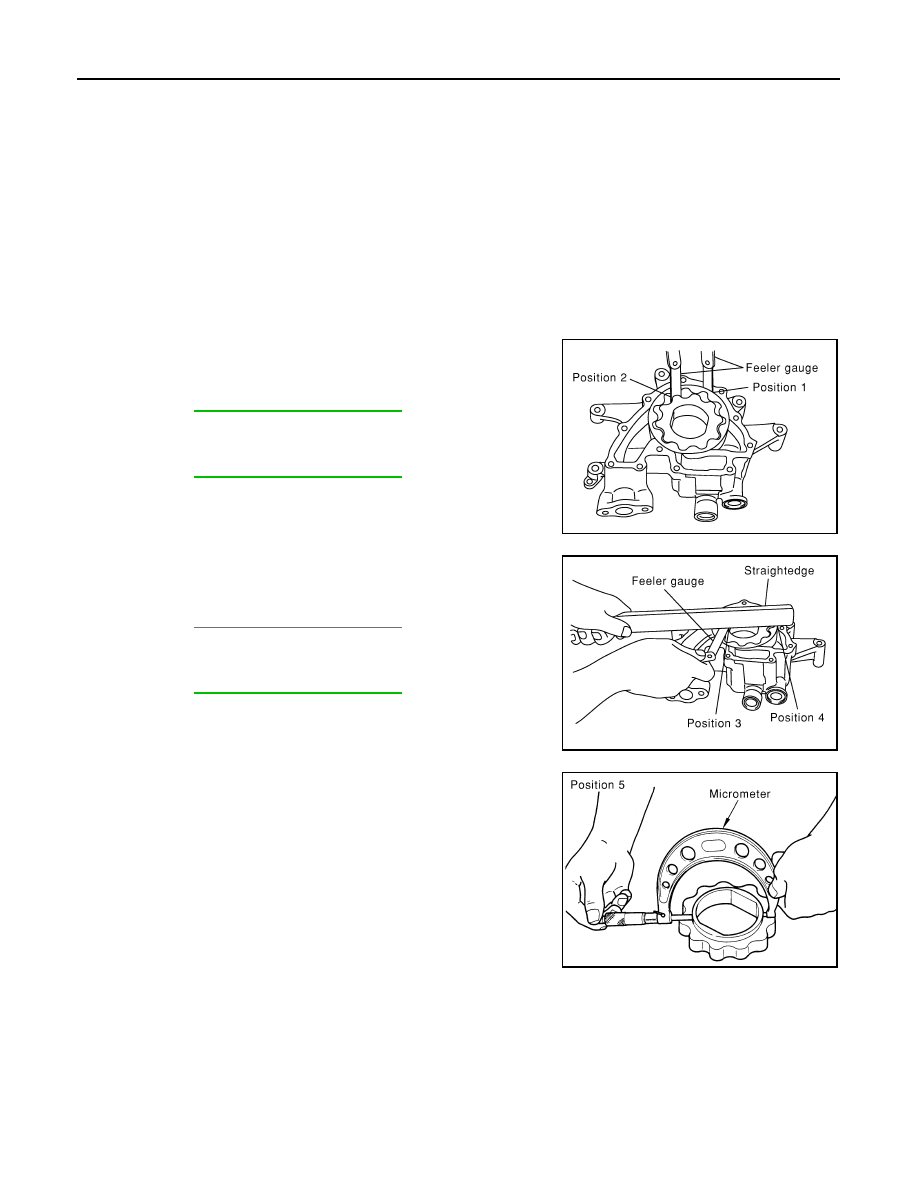

• Measure radial clearance using a suitable tool.

• Measure side clearance using suitable tools.

• Calculate the clearance between inner rotor and oil pump body as

follows.

1. Measure the outer diameter of protruded portion of inner rotor

(position 5) using suitable tool.

Body to outer rotor (position 1)

Refer to

.

Inner rotor to outer rotor tip (position 2)

Refer to

.

PBIC0139E

Body to inner rotor (position 3)

Refer to

.

Body to outer rotor (position 4)

Refer to

.

PBIC0140E

PBIC0141E

August 2012

2012 Pathfinder