Nissan Pathfinder (2012 year). Manual - part 313

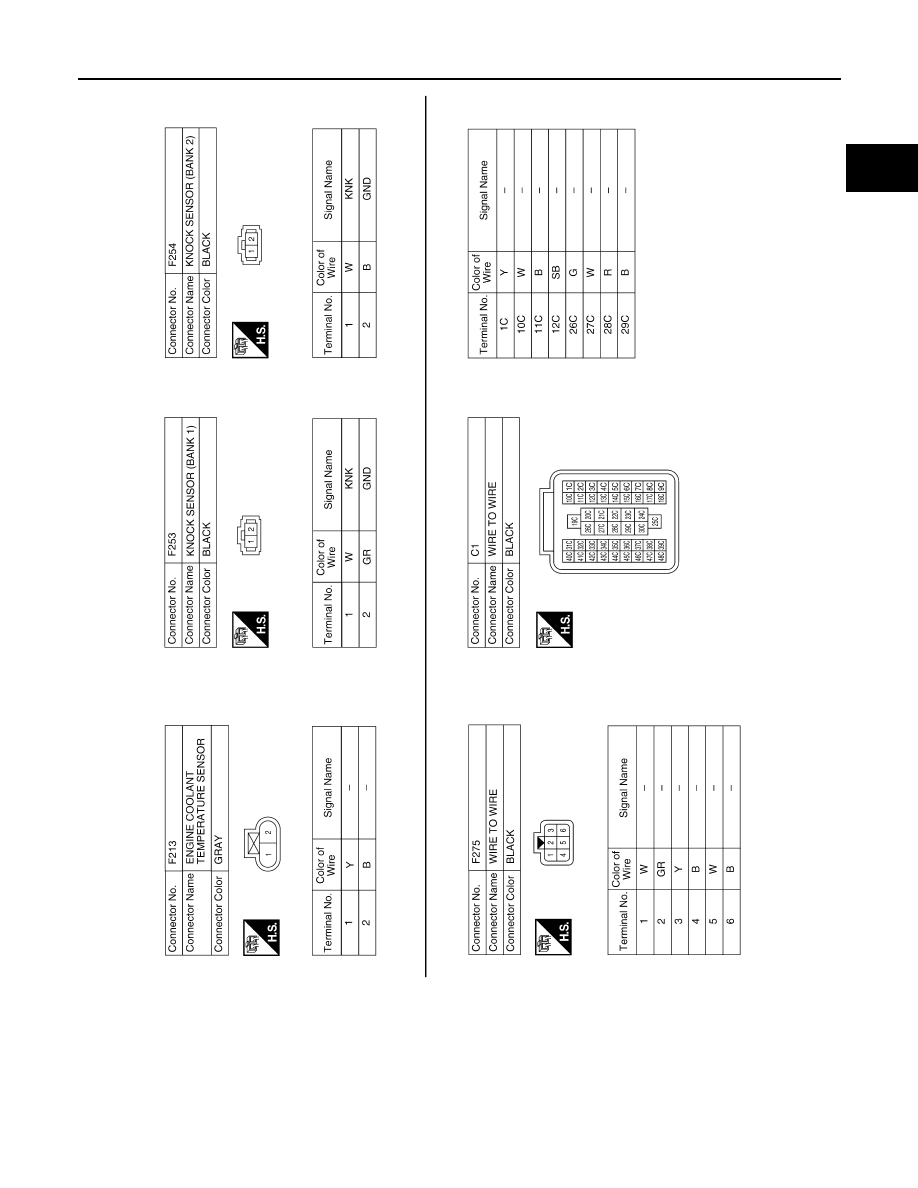

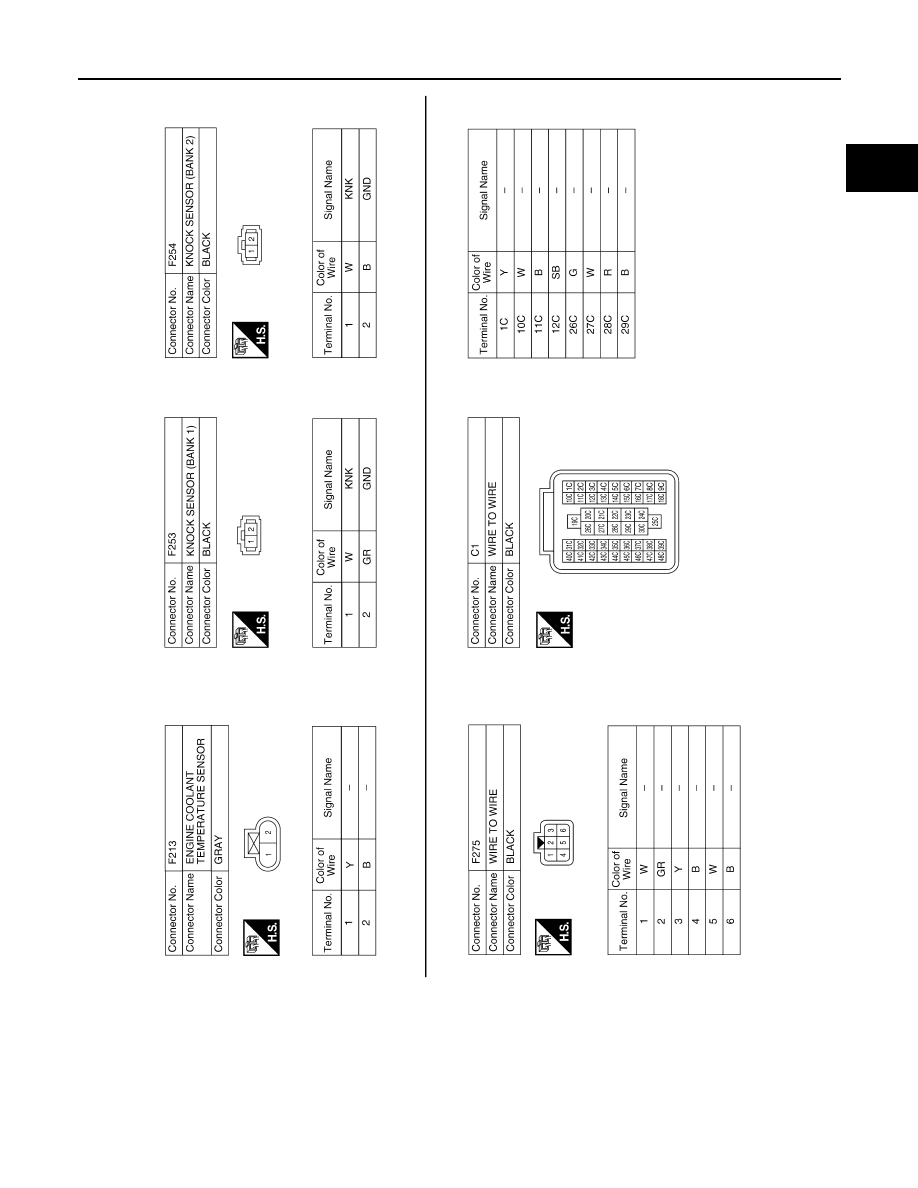

ENGINE CONTROL SYSTEM

EC-585

< WIRING DIAGRAM >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

ABBIA1111GB

August 2012

2012 Pathfinder

|

|

|

ENGINE CONTROL SYSTEM EC-585 < WIRING DIAGRAM > [VK56DE] C D E F G H I J K L M A EC N P O ABBIA1111GB August 2012 2012 Pathfinder |