Nissan Pathfinder (2012 year). Manual - part 229

FRONT FINAL DRIVE

DLN-397

< UNIT DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: M205]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

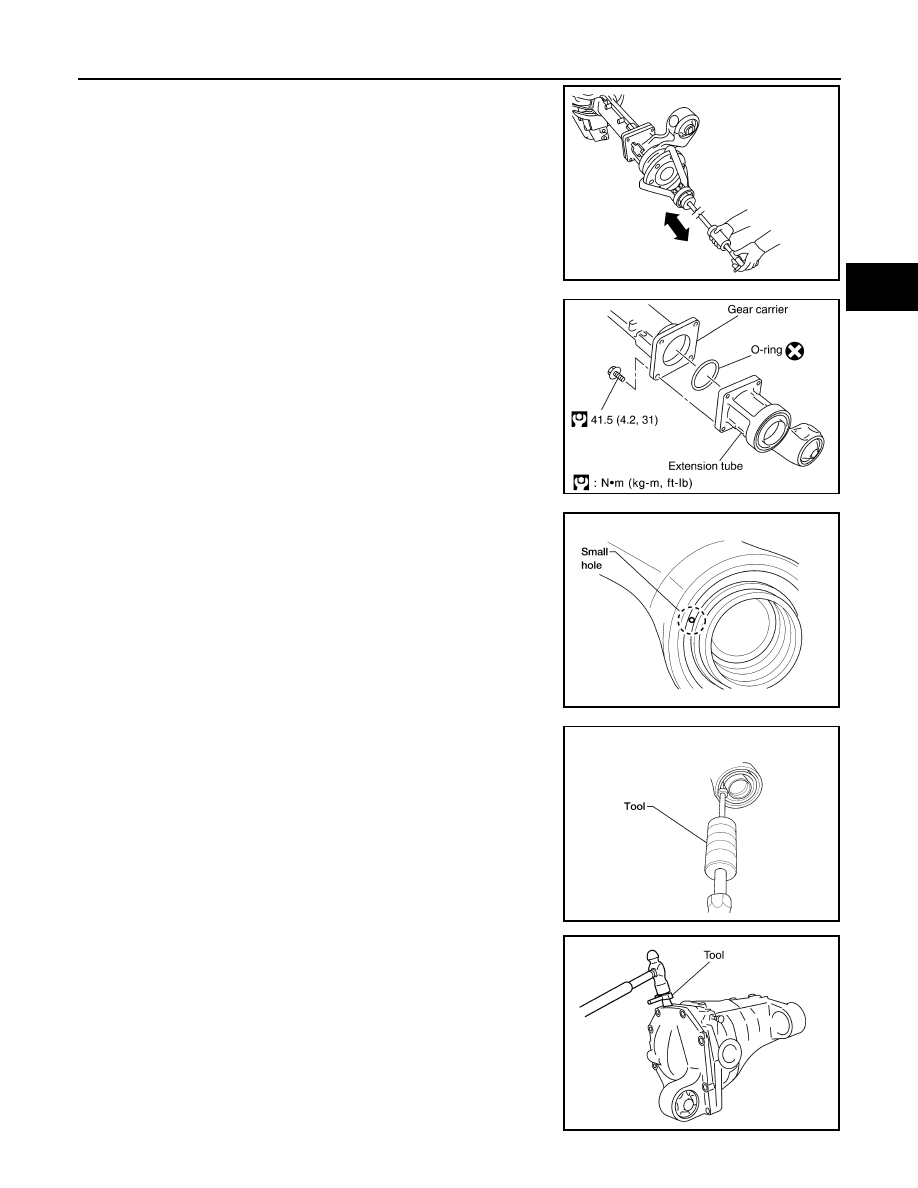

2. Remove the differential side shaft and differential side flange

using suitable tool.

3. Remove the extension tube and O-ring from the gear carrier.

CAUTION:

Do not reuse O-ring.

4. Place a small hole in the side oil seal case using suitable tool.

5. Remove the side oil seal using Tool as shown.

6. Remove the carrier cover bolts and separate the carrier cover

from the gear carrier using Tool.

CAUTION:

• Do not damage the mating surface.

• Do not insert flat-bladed screwdriver, this will damage the

mating surface.

BDIA0006E

SDIA3205E

LDIA0129E

Tool number

: —

SP8P

LDIA0130E

Tool number

: KV10111100 (J-37228)

PDIA0699E

August 2012

2012 Pathfinder