Nissan Pathfinder (2012 year). Manual - part 91

FRONT DISC BRAKE

BR-55

< UNIT DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

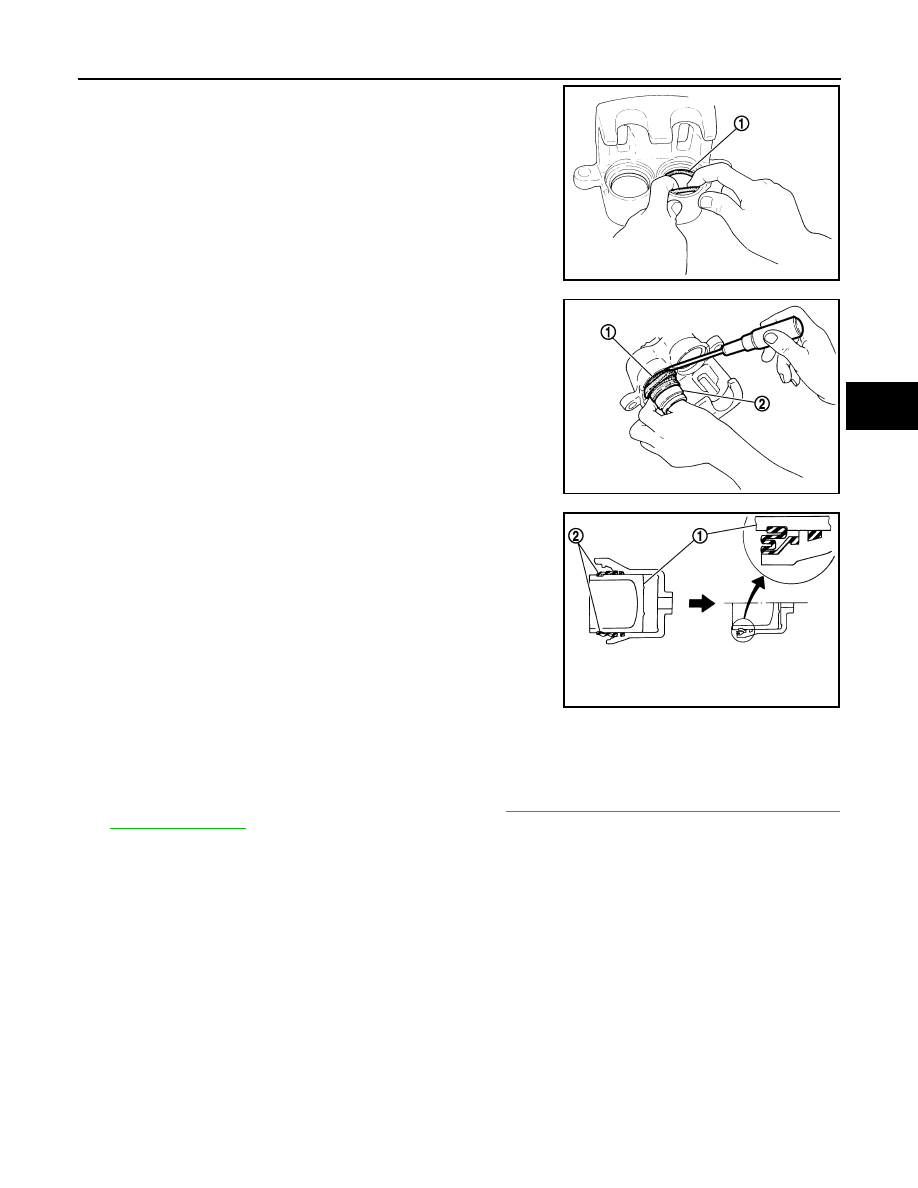

2. Apply rubber grease to the new piston seals (1) and insert the

new piston seals (1) into the groove on the cylinder body.

CAUTION:

Do not reuse piston seals.

3. Apply rubber grease to the new piston boots (1). Cover the pis-

ton end (2) with the piston boot (1), and then install the cylinder

side lip on the piston boot (1) securely into the groove on the cyl-

inder body.

CAUTION:

• Do not reuse piston boot.

• Press pistons in evenly and vary the pressing points to

prevent the cylinder inner wall from being damaged.

4. Install the pistons (1) into the cylinder body and insert the piston

boots (2) side lip into the piston groove as shown.

CAUTION:

Press pistons in evenly and vary the pressing points to pre-

vent the cylinder inner wall from being damaged.

5. Apply rubber grease to the sliding pin boots, then install the new upper sliding pin, lower sliding pin, and

sliding pin boots on the torque member.

CAUTION:

Upper sliding pin must be replaced at each service.

6. Install the cylinder body on the torque member. Refer to

BR-42, "Removal and Installation of Brake Cali-

.

JPFIA0032ZZ

JPFIA0033ZZ

JPFIA0034ZZ

August 2012

2012 Pathfinder