Nissan Pathfinder (2010 year). Manual - part 473

INTERIOR ROOM LAMP

INL-67

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

M

A

B

INL

N

O

P

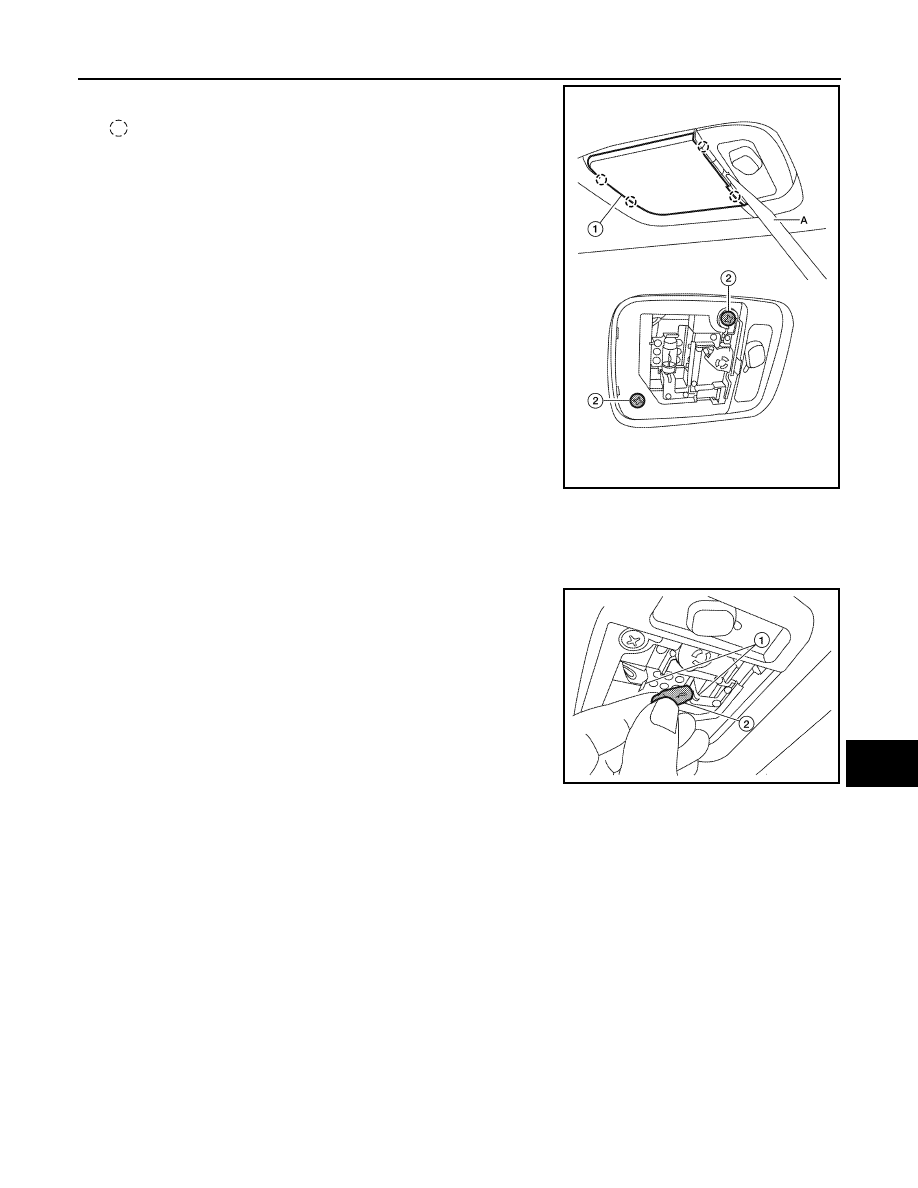

1. Using a suitable tool (A), release the pawls and remove the

cargo lamp lens (1).

: Pawl

CAUTION:

Wrap a cloth around tool to protect the housing and lens.

2. Remove cargo lamp screws (2).

3. Disconnect the connector, then remove cargo lamp.

Installation

Installation is in the reverse order of removal.

Bulb Replacement

1. Using a suitable tool, release the pawls and remove the cargo lamp lens.

2. Release the cargo lamp bulb retainers (1), then pull bulb (2)

straight out to remove.

CARGO LAMP

Removal

AWLIA1670ZZ

Room lamp bulb

: 12V - 8W

ALLIA0326ZZ

2010 Pathfinder