Nissan Pathfinder (2010 year). Manual - part 376

EM-136

< SERVICE DATA AND SPECIFICATIONS (SDS)

[VQ40DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

1

: Always check with the Parts Department for the latest parts information

2

: Total indicator reading

MAIN BEARING

Main journal diameter. “Dm” grade

Standard

Grade

1

Dimension

Grade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 4

Grade No. 7

69.975 - 69.974 (2.7549 - 2.7549)

69.974 - 69.973 (2.7549 - 2.7548)

69.973 - 69.972 (2.7548 - 2.7548)

69.972 - 69.971 (2.7548 - 2.7548)

69.971 - 69.970 (2.7548 - 2.7547)

69.970 - 69.969 (2.7547 - 2.7547)

69.969 - 69.968 (2.7547 - 2.7546)

69.968 - 69.967 (2.7546 - 2.7546)

69.967 - 69.966 (2.7546 - 2.7546)

69.966 - 69.965 (2.7546 - 2.7545)

69.965 - 69.964 (2.7545 - 2.7545)

69.964 - 69.963 (2.7545 - 2.7544)

69.963 - 69.962 (2.7544 - 2.7544)

69.962 - 69.961 (2.7544 - 2.7544)

69.961 - 69.960 (2.7544 - 2.7543)

69.960 - 69.959 (2.7543 - 2.7543)

69.959 - 69.958 (2.7543 - 2.7542)

69.958 - 69.957 (2.7542 - 2.7542)

69.957 - 69.956 (2.7542 - 2.7542)

69.956 - 69.955 (2.7542 - 2.7541)

69.955 - 69.954 (2.7541 - 2.7541)

69.954 - 69.953 (2.7541 - 2.7540)

69.953 - 69.952 (2.7540 - 2.7540)

69.952 - 69.951 (2.7540 - 2.7540)

Pin journal diameter. “Dp” grade

Standard

Grade No. 0

53.968 - 53.974 (2.1247 - 2.1250)

Grade No. 1

53.962 - 53.968 (2.1245 - 2.1247)

Grade No. 2

53.956 - 53.962 (2.1242 - 2.1245)

Center distance “r”

45.96 - 46.04 (1.8094 - 1.8126)

Taper (Difference between “A” and “B”)

Limit

0.002 (0.0001)

Out-of-round (Difference between “X” and “Y”)

0.002 (0.0001)

Crankshaft runout [TIR

2

]

Standard

Less than 0.05 (0.002)

Limit

0.10 (0.0039)

Crankshaft end play

Standard

0.10 - 0.25 (0.0039 - 0.0098)

Limit

0.30 (0.0118)

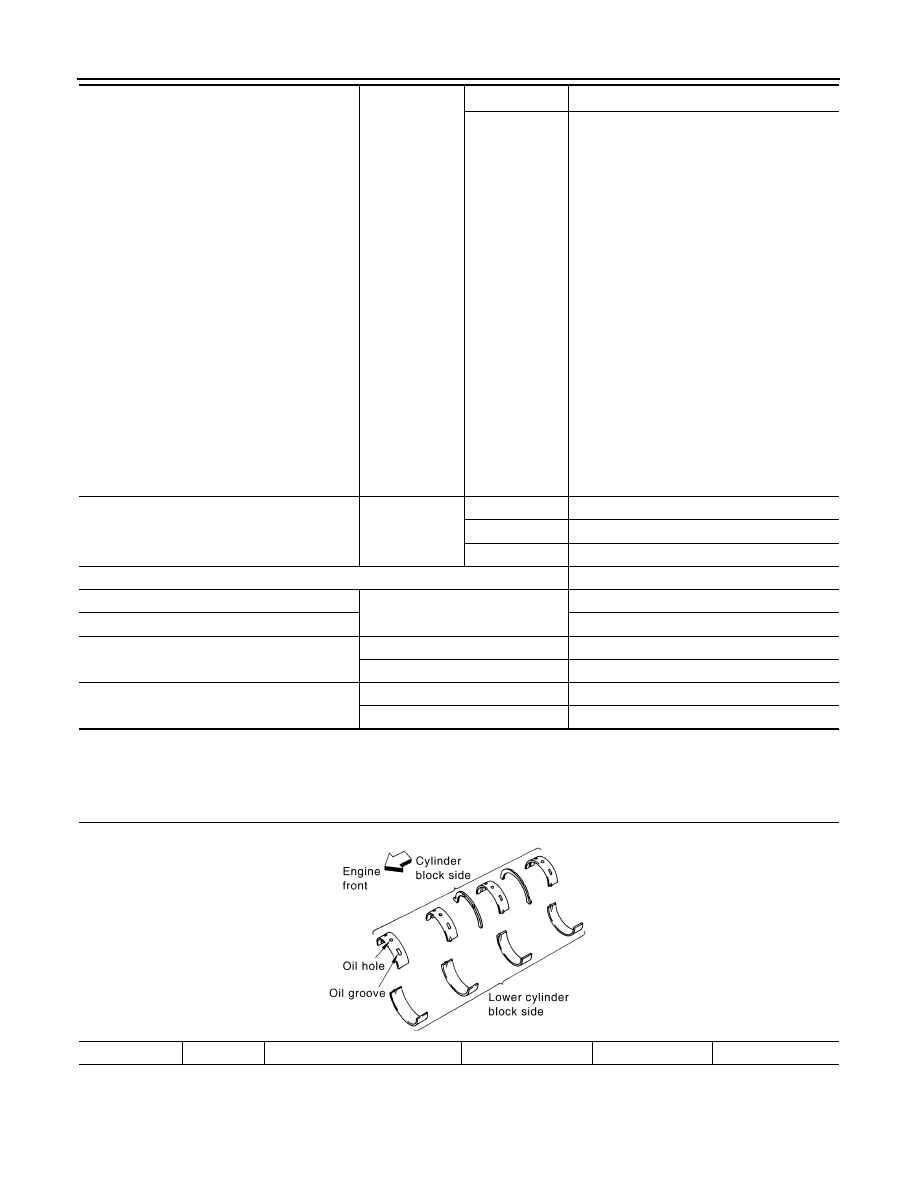

Grade number*

UPR/LWR

Thickness mm (in)

Width mm (in)

Identification color

Remarks

PBIC2969E

2010 Pathfinder