Nissan Pathfinder (2010 year). Manual - part 125

CHG-22

< ON-VEHICLE REPAIR >

GENERATOR

• For this model, the power generation variable voltage control system that controls the power generation volt-

age of the generator has been adopted. Therefore, the power generation variable voltage control system

inspection should be performed after replacing the generator in order to ensure that the system operates

normally.

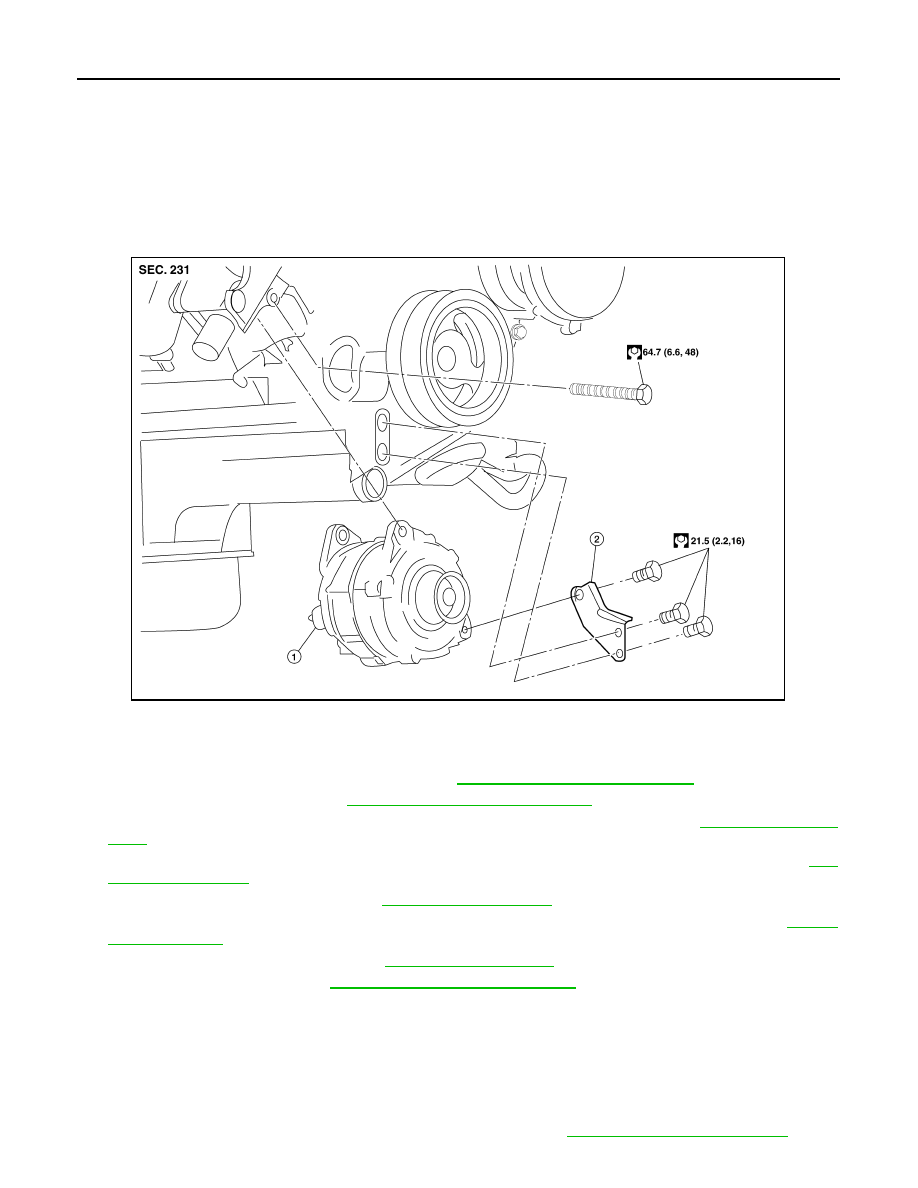

VK56DE MODELS

Removal

1. Disconnect the negative battery terminal. Refer to

PG-78, "Removal and Installation"

2. Drain the engine coolant. Refer to

CO-40, "Changing Engine Coolant"

.

3. Remove air duct and resonator assembly and air cleaner case (upper). Refer to

.

4. Disconnect the lower radiator hose and the transmission oil cooler hoses from the radiator. Refer to

5. Remove the lower fan shroud. Refer to

6. Disconnect the upper radiator hose and the coolant reservoir hose from the radiator. Refer to

7. Remove the upper fan shroud. Refer to

.

8. Remove the drive belt. Refer to

EM-149, "Removal and Installation"

.

9. Remove the lower bracket, using power tools.

10. Remove the generator upper bolt, using power tools.

11. Disconnect the generator harness connectors.

12. Remove the generator.

Installation

Installation is in the reverse order of removal.

• Install the generator and check the tension of the drive belt. Refer to

EM-149, "Checking Drive Belts"

Terminal nut

: 10.8 N·m (1.1 kg-m, 8 ft-lb)

1.

Generator

2.

Lower bracket

AWBIA0701GB

2010 Pathfinder