Nissan Pathfinder (2008 year). Manual - part 495

MWI

POWER SUPPLY AND GROUND CIRCUIT

MWI-31

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

M

B

A

O

P

Is the fuse blown?

YES

>> Replace the blown fuse or fusible link after repairing the affected circuit.

NO

>> GO TO 2

2.

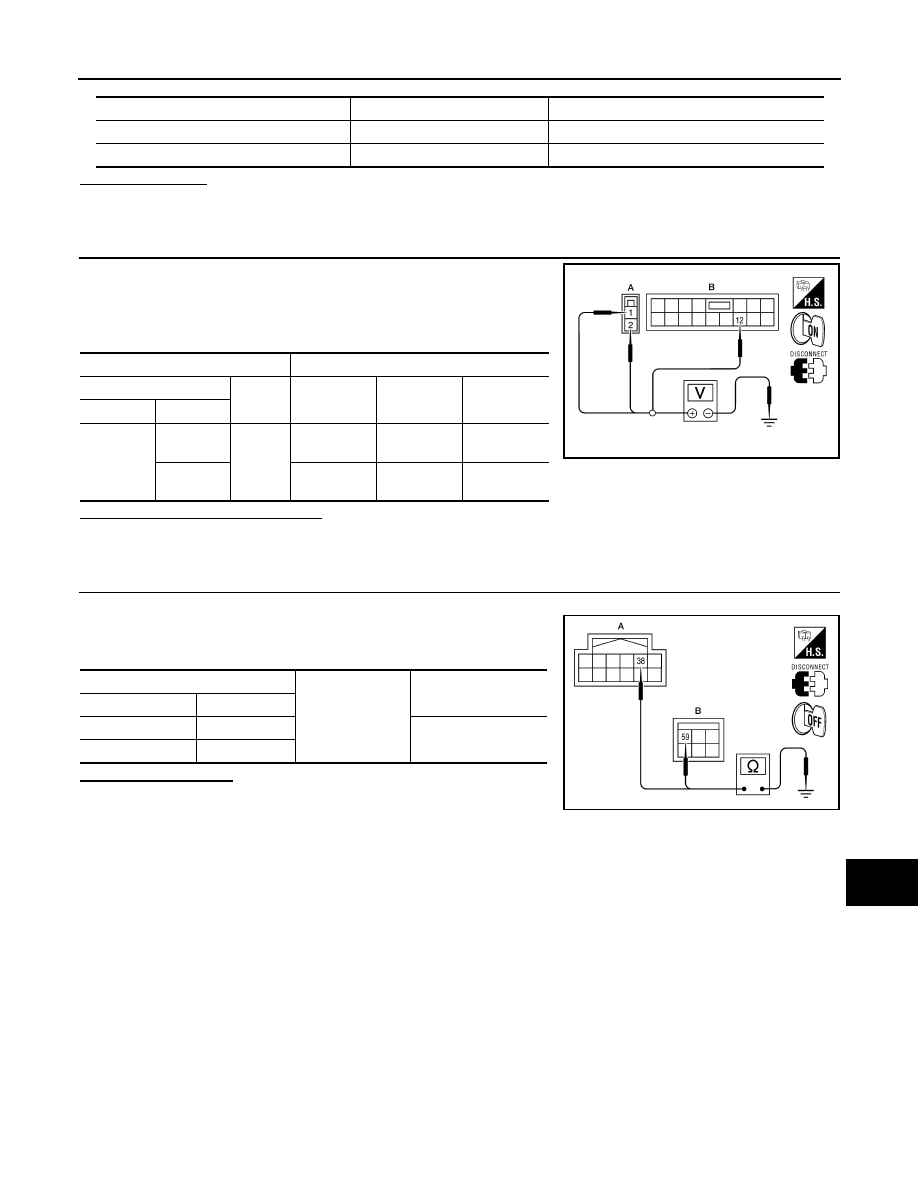

CHECK BATTERY POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect IPDM E/R.

3.

Check voltage between IPDM E/R harness connectors and

ground.

Is the measurement value normal?

YES

>> GO TO 3

NO

>> Repair or replace harness.

3.

CHECK GROUND CIRCUIT

1.

Turn ignition switch OFF.

2.

Check continuity between IPDM E/R harness connectors and

ground.

Does continuity exist?

YES

>> Inspection End.

NO

>> Repair or replace harness.

Terminal No.

Signal name

Fuses and fusible link No.

1

Battery

A, D

2

Battery

C

Terminals

Ignition switch position

(+)

(

−

)

OFF

ON

START

Connector

Terminal

E118 (A)

1

Ground

Battery

voltage

Battery

voltage

Battery

voltage

2

Battery

voltage

Battery

voltage

Battery

voltage

AWMIA0023ZZ

IPDM E/R

Ground

Continuity

Connector

Terminal

E122 (A)

38

Yes

E124 (B)

59

AWMIA0024ZZ