Nissan Pathfinder (2008 year). Manual - part 230

DLN-424

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R200]

REAR FINAL DRIVE

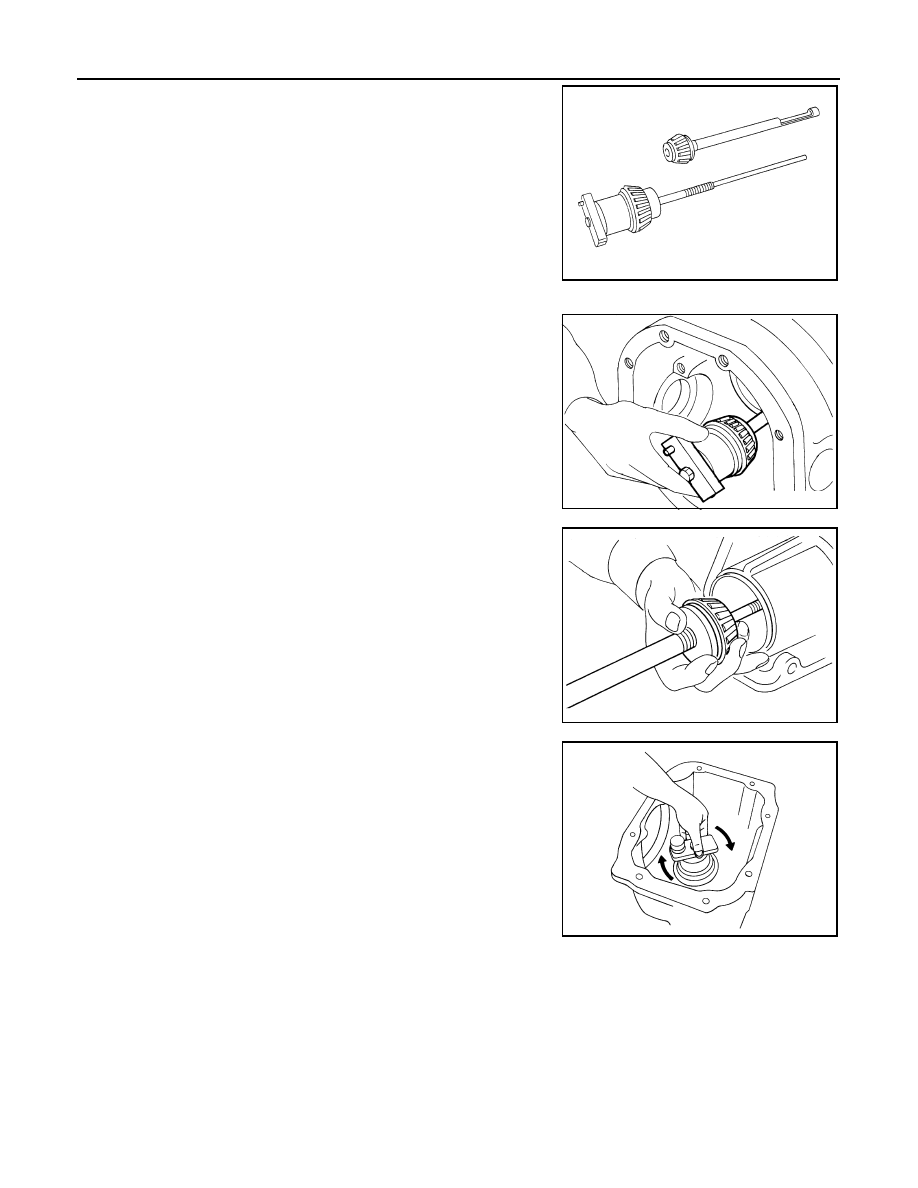

• Drive pinion front bearing; make sure the J-34309-3 drive

pinion front bearing seat is secured tightly against the J-

34309-2 gauge anvil. Then turn the J-34309-5 drive pinion

front bearing pilot to secure the drive pinion bearing in its

proper position.

• Drive pinion rear bearing; the J-34309-8 drive pinion rear

bearing pilot is used to center the drive pinion rear bearing

only. The J-34309-4 drive pinion rear bearing locking seat is

used to lock the drive pinion rear bearing to the assembly.

• Installation of J-34309-9 and J-34309-16; place a suitable

2.5 mm (0.098 in) thick plain washer between J-34309-9 and

J-34309-16. Both surfaces of J-34309-9 and J-34309-16 must

be parallel with a clearance of 2.5 mm (0.098 in).

3.

Install the drive pinion rear bearing inner race into the gear car-

rier. Then insert the drive pinion height adjusting washer selec-

tor tool, J-34309-1, gauge screw assembly.

4.

Assemble the drive pinion front bearing inner race and the J-

34309-2 gauge anvil. Assemble them together with the J-34309-

1 gauge screw in the gear carrier. Make sure that the drive pin-

ion height gauge plate, J-34309-16, will turn a full 360

°

. Tighten

the two sections together by hand.

5.

Turn the assembly several times to seat the drive pinion bear-

ings.

SPD197A

SPD893

SPD199A

SPD770