Nissan Pathfinder (2007 year). Manual - part 314

OIL COOLER

LU-11

C

D

E

F

G

H

I

J

K

L

M

A

LU

2007 Pathfinder

OIL COOLER

PFP:21305

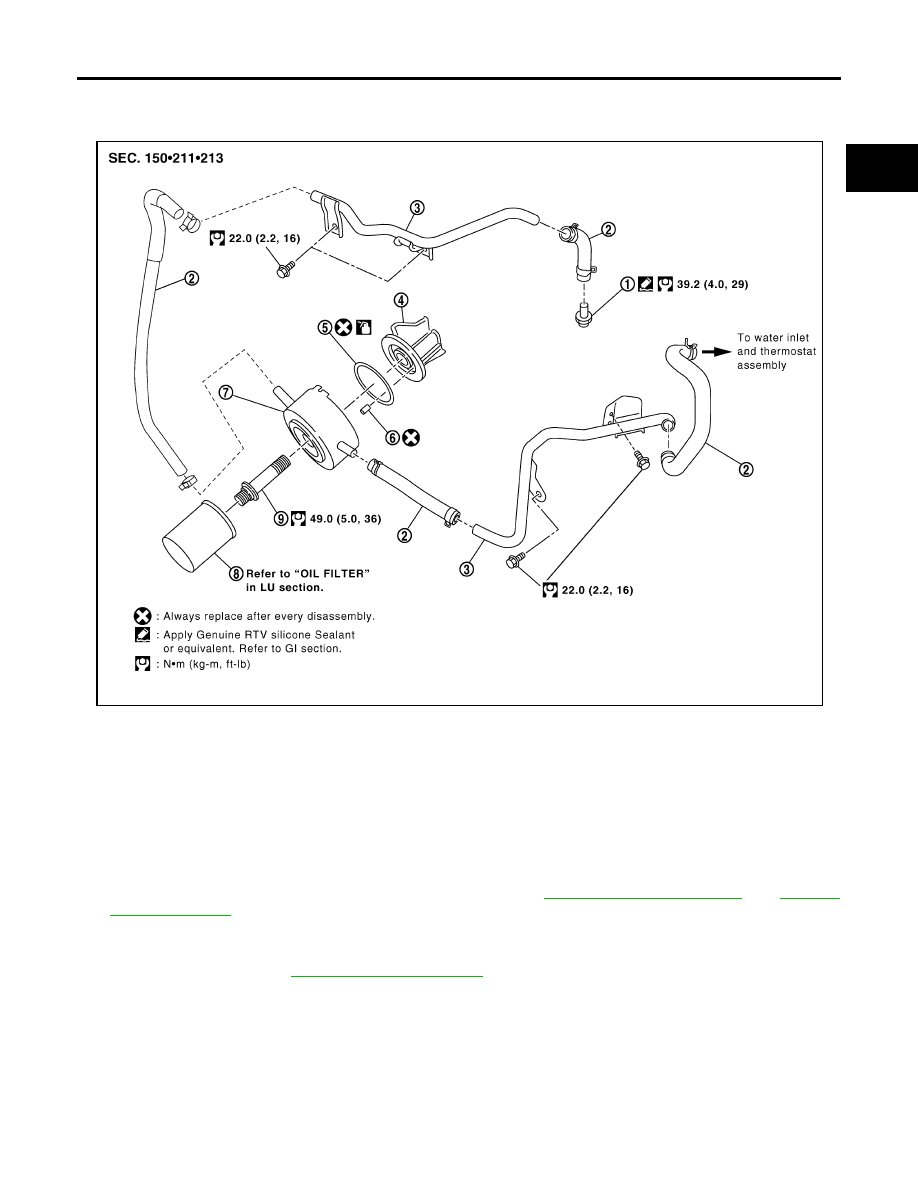

Removal and Installation

EBS00QCM

WARNING:

Be careful not to get burn yourself, as engine oil and engine coolant are hot.

REMOVAL

NOTE:

When removing oil cooler only, step 1 is unnecessary.

1.

Drain engine coolant from radiator and cylinder block. Refer to

and

NOTE:

Perform this step when removing water pipes.

2.

Remove oil filter. Refer to

.

CAUTION:

Do not spill engine oil on drive belts.

3.

Disconnect water hoses from oil cooler.

●

When removing oil cooler only, pinching water hoses near oil cooler to prevent engine coolant spilling.

CAUTION:

●

Perform this step when engine is cold.

●

Do not spill engine coolant on drive belts.

4.

Remove connector bolt, and remove oil cooler.

1.

Water connector

2.

Water hose

3.

Water pipe

4.

Oil pan (upper) front side

5.

O-ring

6.

Relief valve

7.

Oil cooler

8.

Oil filter

9.

Connector bolt

WBIA0572E