Nissan Pathfinder (2007 year). Manual - part 241

CAMSHAFT

EM-85

C

D

E

F

G

H

I

J

K

L

M

A

EM

2007 Pathfinder

b.

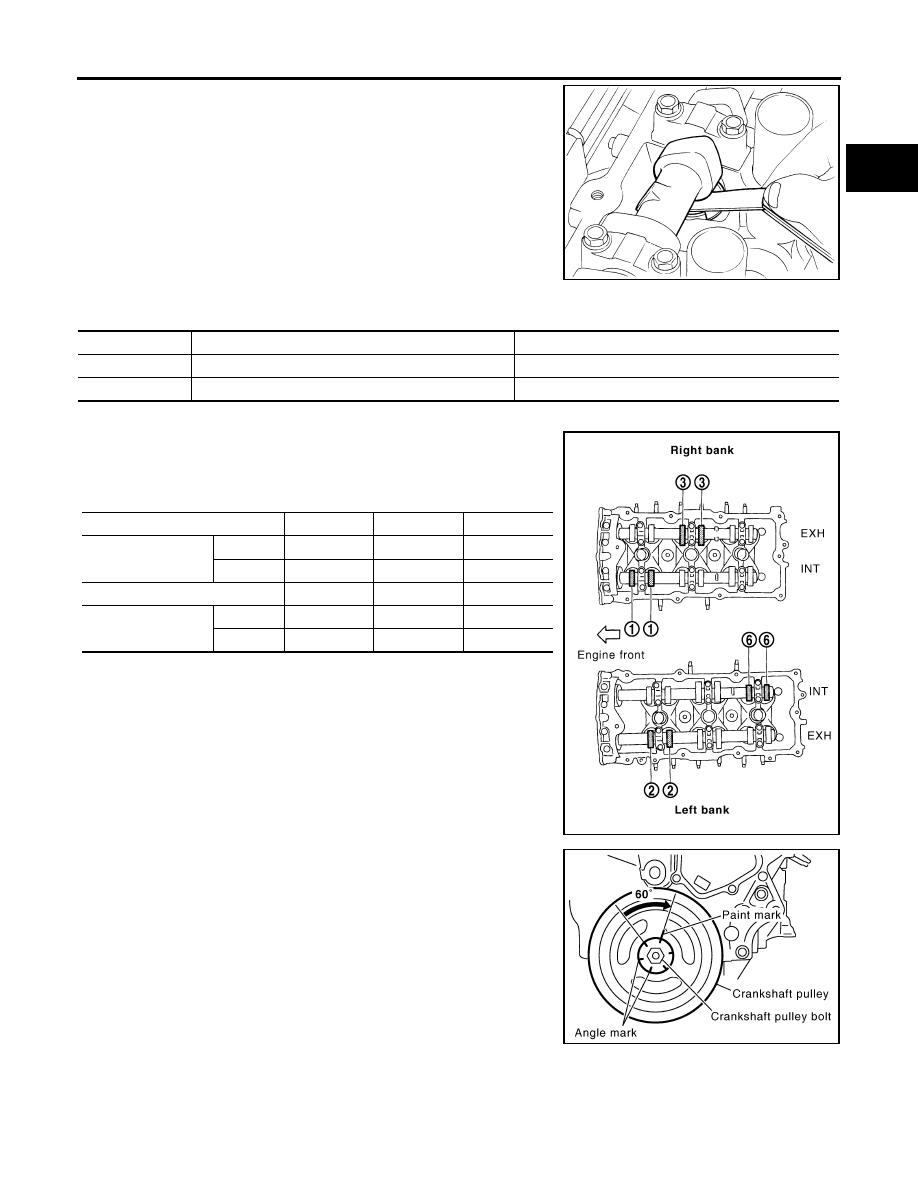

Use feeler gauge, measure the clearance between valve lifter

and camshaft.

Valve clearance:

Unit: mm (in)

*: Approximately 80

°

C (176

°

F)

●

By referring to the figure, measure the valve clearances at

locations marked “

×

” as shown (locations indicated in the fig-

ure) with feeler gauge.

●

No. 1 cylinder at compression TDC

c.

Rotate crankshaft by 240

°

clockwise (when viewed from engine

front) to align No. 3 cylinder at TDC of its compression stroke.

NOTE:

Crankshaft pulley bolt flange has a stamped line every 60

°

. They

can be used as a guide to rotation angle.

SEM139D

Cold

Hot * (reference data)

Intake

0.26 - 0.34 (0.010 - 0.013)

0.304 - 0.416 (0.012 - 0.016)

Exhaust

0.29 - 0.37 (0.011 - 0.015)

0.308 - 0.432 (0.012 - 0.017)

Measuring position (right bank)

No. 1 CYL.

No. 3 CYL.

No. 5 CYL.

No. 1 cylinder at

compression TDC

EXH

×

INT

×

Measuring position (left bank)

No. 2 CYL.

No. 4 CYL.

No. 6 CYL.

No. 1 cylinder at

compression TDC

INT

×

EXH

×

PBIC2054E

PBIC2916E