Nissan Pathfinder (2007 year). Manual - part 195

DTC P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-427

C

D

E

F

G

H

I

J

K

L

M

A

EC

2007 Pathfinder

DTC P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

PFP:25085

Component Description

UBS00K9Y

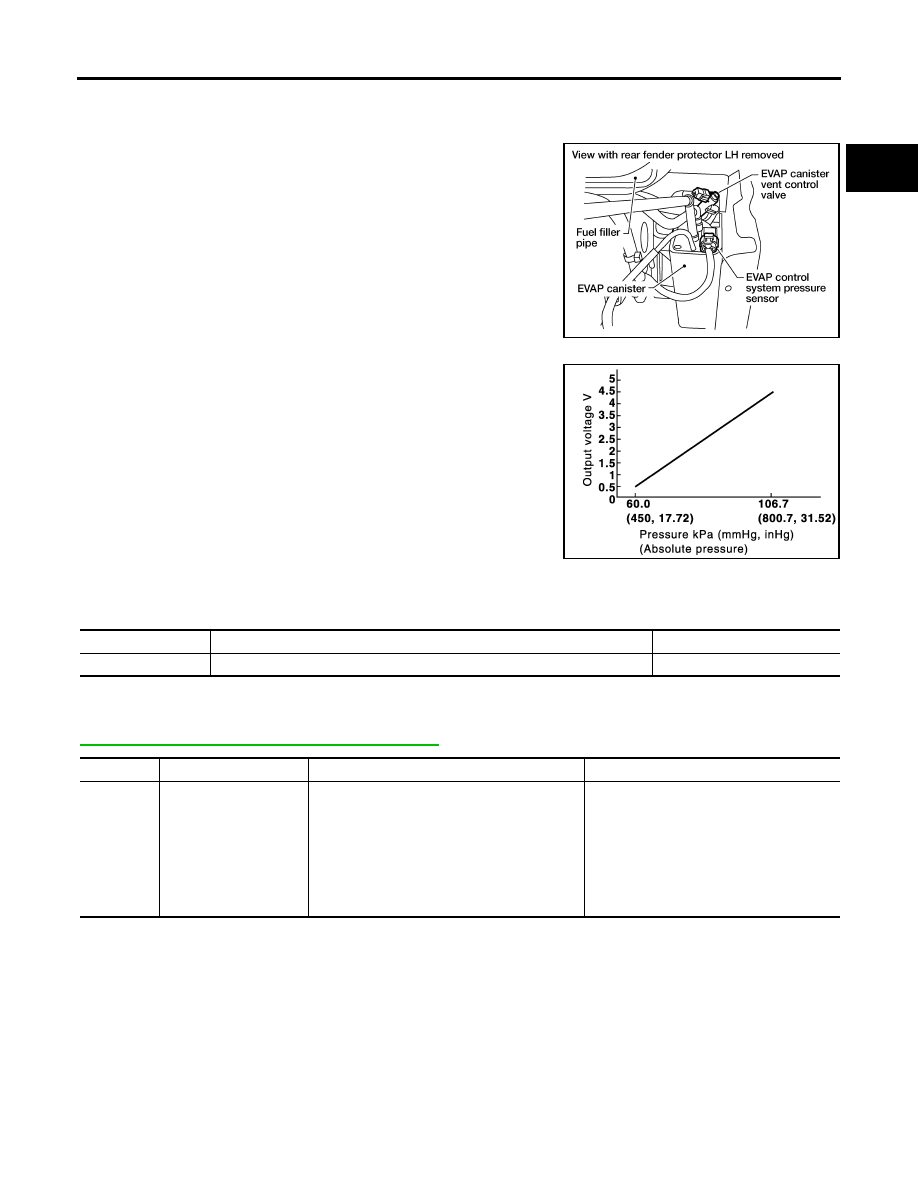

The EVAP control system pressure sensor detects pressure in the

purge line. The sensor output voltage to the ECM increases as pres-

sure increases.

CONSULT-II Reference Value in Data Monitor Mode

UBS00K9Z

Specification data are reference values.

On Board Diagnosis Logic

UBS00KA0

If DTC P0453 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to

EC-475, "DTC P0643 SENSOR POWER SUPPLY"

BBIA0551E

PBIB1207E

MONITOR ITEM

CONDITION

SPECIFICATION

EVAP SYS PRES

●

Ignition switch: ON

Approx. 1.8 - 4.8V

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0453

0453

EVAP control system

pressure sensor high

input

An excessively high voltage from the sensor is

sent to ECM.

●

Harness or connectors

(The sensor circuit is open or shorted.)

●

EVAP control system pressure sensor

●

EVAP canister vent control valve

●

EVAP canister

●

Rubber hose from EVAP canister vent

control valve to vehicle frame