Nissan Pathfinder (2007 year). Manual - part 7

A/T CONTROL SYSTEM

AT-27

D

E

F

G

H

I

J

K

L

M

A

B

AT

2007 Pathfinder

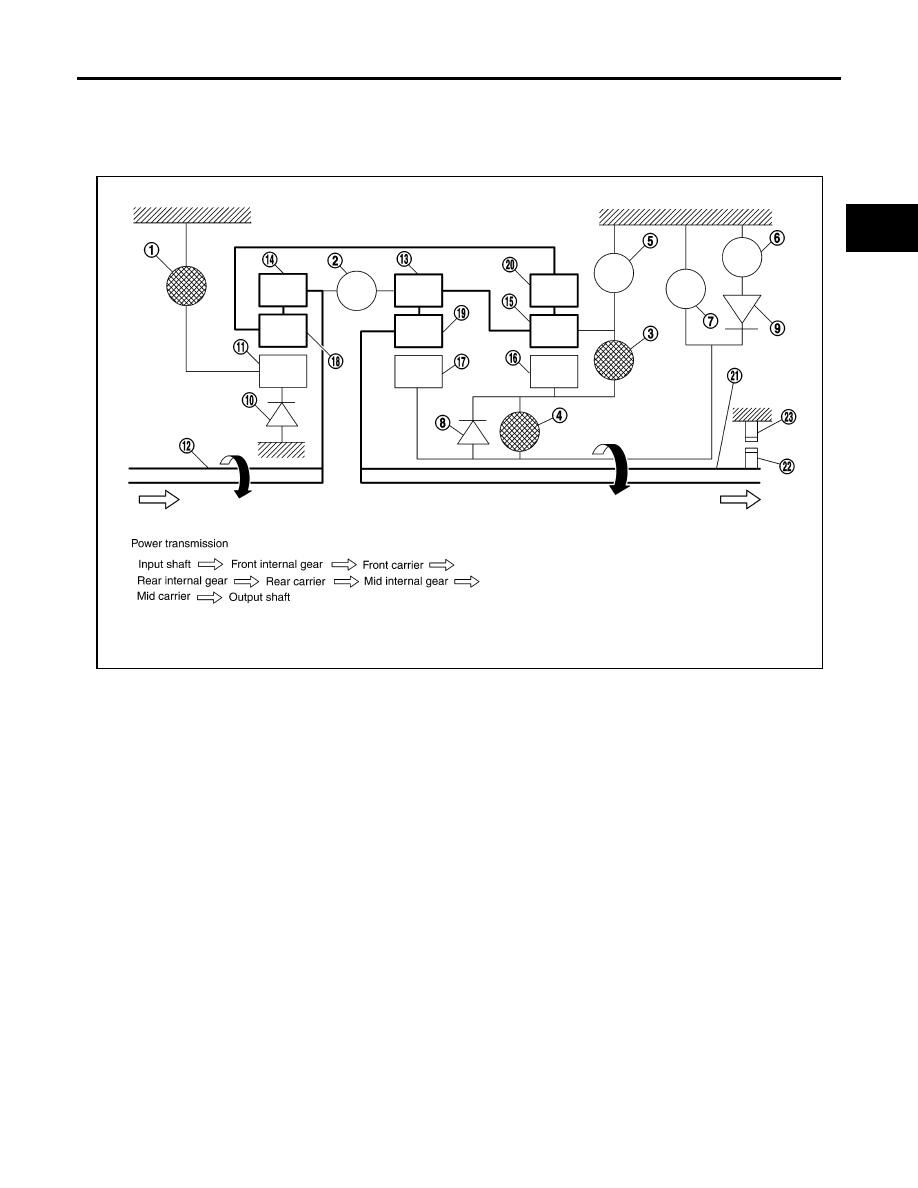

“D” and “3” Positions 3rd Gear

●

The front brake fastens the front sun gear.

●

The direct clutch is coupled, and the rear carrier and rear sun gear are connected.

●

The high and low reverse clutch is coupled and the mid sun gear and rear sun gear are connected.

1.

Front brake

2.

Input clutch

3.

Direct clutch

4.

High and low reverse clutch

5.

Reverse brake

6.

Forward brake

7.

Low coast brake

8.

1st one-way clutch

9.

Forward one-way clutch

10. 3rd one-way clutch

11.

Front sun gear

12. Input shaft

13. Mid internal gear

14. Front internal gear

15. Rear carrier

16. Rear sun gear

17. Mid sun gear

18. Front carrier

19. Mid carrier

20. Rear internal gear

21. Output shaft

22. Parking gear

23. Parking pawl

SCIA1516E