Nissan Pathfinder (2006 year). Manual - part 199

DTC P0456 EVAP CONTROL SYSTEM

EC-451

C

D

E

F

G

H

I

J

K

L

M

A

EC

2006 Pathfinder

7.

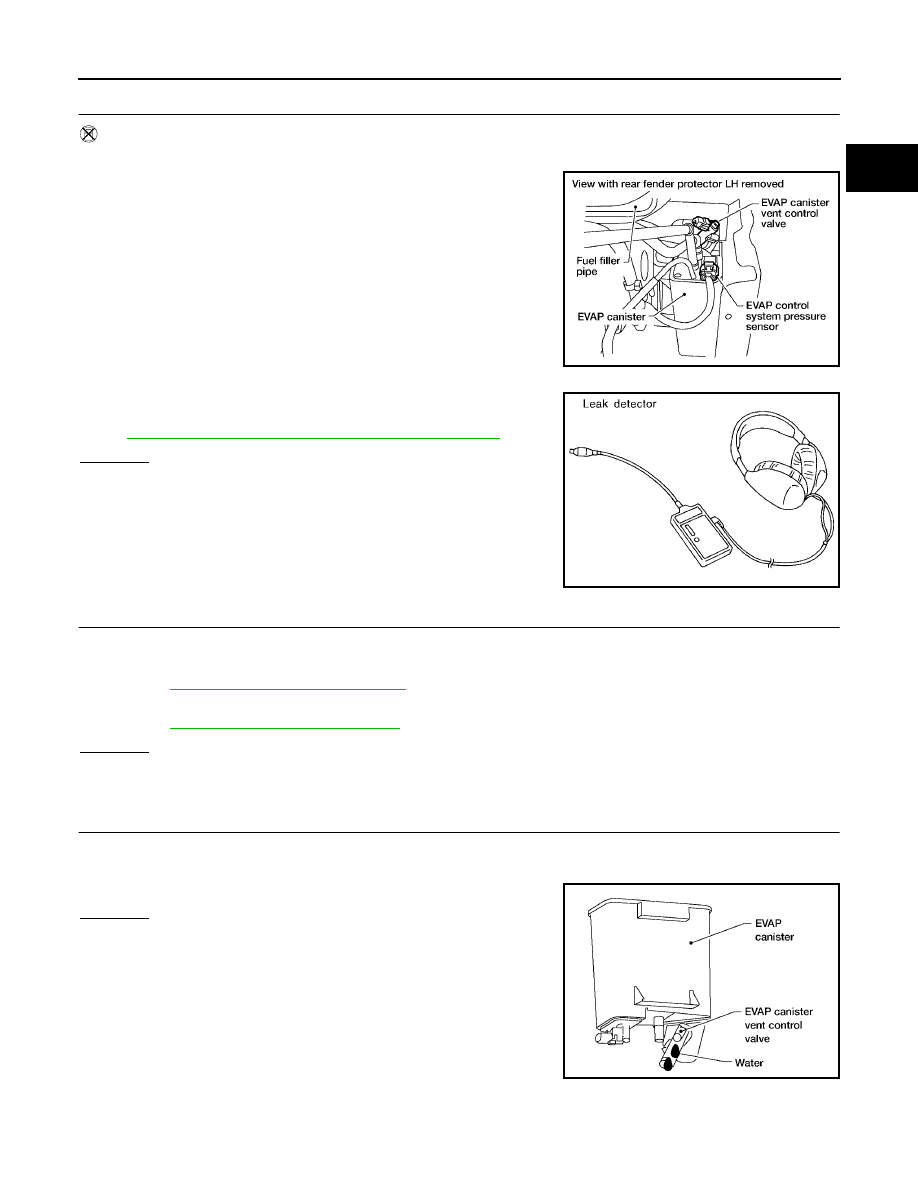

CHECK FOR EVAP LEAK

Without CONSULT-II

1.

Turn ignition switch OFF.

2.

Apply 12 volts DC to EVAP canister vent control valve. The

valve will close. (Continue to apply 12 volts until the end of test.)

3.

Pressurize the EVAP line using pressure pump with 1.3 to 2.7

kPa (10 to 20 mmHg, 0.39 to 0.79 inHg), then remove pump and

EVAP service port adapter.

CAUTION:

●

Never use compressed air or a high pressure pump.

●

Do not exceed 4.12 kPa (0.042 kg/cm

2

, 0.6 psi) of pres-

sure in the system.

4.

Using EVAP leak detector, locate the EVAP leak. For the leak

detector, refer to the instruction manual for more details. Refer

to

EC-33, "EVAPORATIVE EMISSION LINE DRAWING"

OK or NG

OK

>> GO TO 8.

NG

>> Repair or replace.

8.

CHECK EVAP CANISTER VENT CONTROL VALVE

Check the following.

●

EVAP canister vent control valve is installed properly.

Refer to

EC-36, "Removal and Installation"

●

EVAP canister vent control valve.

Refer to

EC-414, "Component Inspection"

OK or NG

OK

>> GO TO 9.

NG

>> Repair or replace EVAP canister vent control valve and O-ring.

9.

CHECK IF EVAP CANISTER SATURATED WITH WATER

1.

Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

2.

Does water drain from the EVAP canister?

Yes or No

Yes

>> GO TO 10.

No (With CONSULT-II)>>GO TO 12.

No (Without CONSULT-II)>>GO TO 13.

BBIA0551E

SEF200U

BBIA0558E