Nissan Pathfinder (2006 year). Manual - part 191

DTC P0442 EVAP CONTROL SYSTEM

EC-387

C

D

E

F

G

H

I

J

K

L

M

A

EC

2006 Pathfinder

CAUTION:

●

Use only a genuine NISSAN fuel filler cap as a replacement. If an incorrect fuel filler cap is used,

the MIL may come on.

●

If the fuel filler cap is not tightened properly, the MIL may come on.

●

Use only a genuine NISSAN rubber tube as a replacement.

DTC Confirmation Procedure

UBS00K94

NOTE:

●

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait

at least 10 seconds before conducting the next test.

TESTING CONDITION:

●

Perform “DTC WORK SUPPORT” when the fuel level is between 1/4 and 3/4 full, and vehicle is

placed on flat level surface.

●

Always perform test at a temperature of 0 to 30

°

C (32 to 86

°

F).

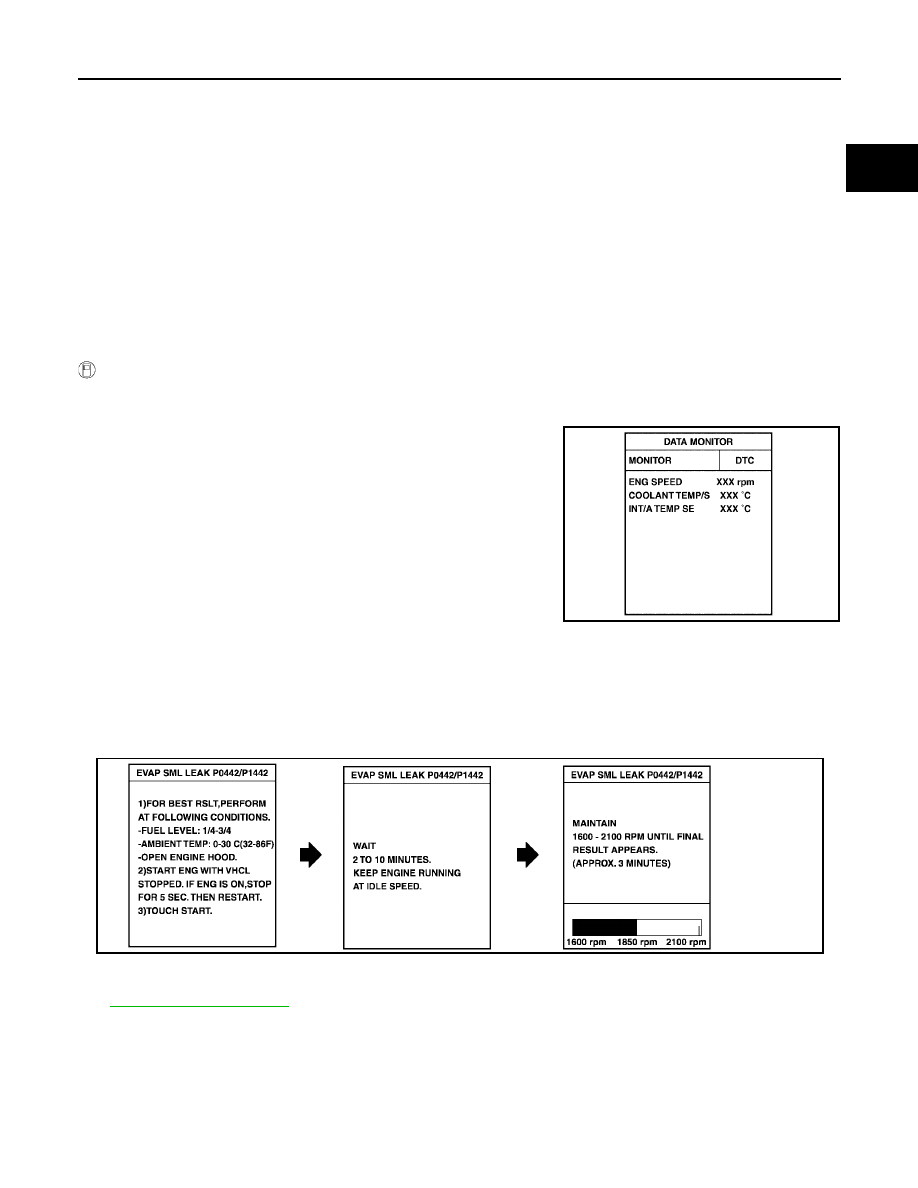

WITH CONSULT-II

1.

Turn ignition switch ON.

2.

Turn ignition switch OFF and wait at least 10 seconds.

3.

Turn ignition switch ON and select “DATA MONITOR” mode with

CONSULT-II.

4.

Make sure that the following conditions are met.

COOLAN TEMP/S: 0 - 70

°

C (32 - 158

°

F)

INT/A TEMP SE: 0 - 30

°

C (32 - 86

°

F)

5.

Select “EVP SML LEAK P0442/P1442” of “EVAPORATIVE SYSTEM” in “DTC WORK SUPPORT” mode

with CONSULT-II.

Follow the instruction displayed.

NOTE:

If the engine speed cannot be maintained within the range displayed on the CONSULT-II screen, go to

.

PBIB2643E

PBIB0829E