Nissan Pathfinder (2006 year). Manual - part 142

WARNING CHIME

DI-57

C

D

E

F

G

H

I

J

L

M

A

B

DI

2006 Pathfinder

5.

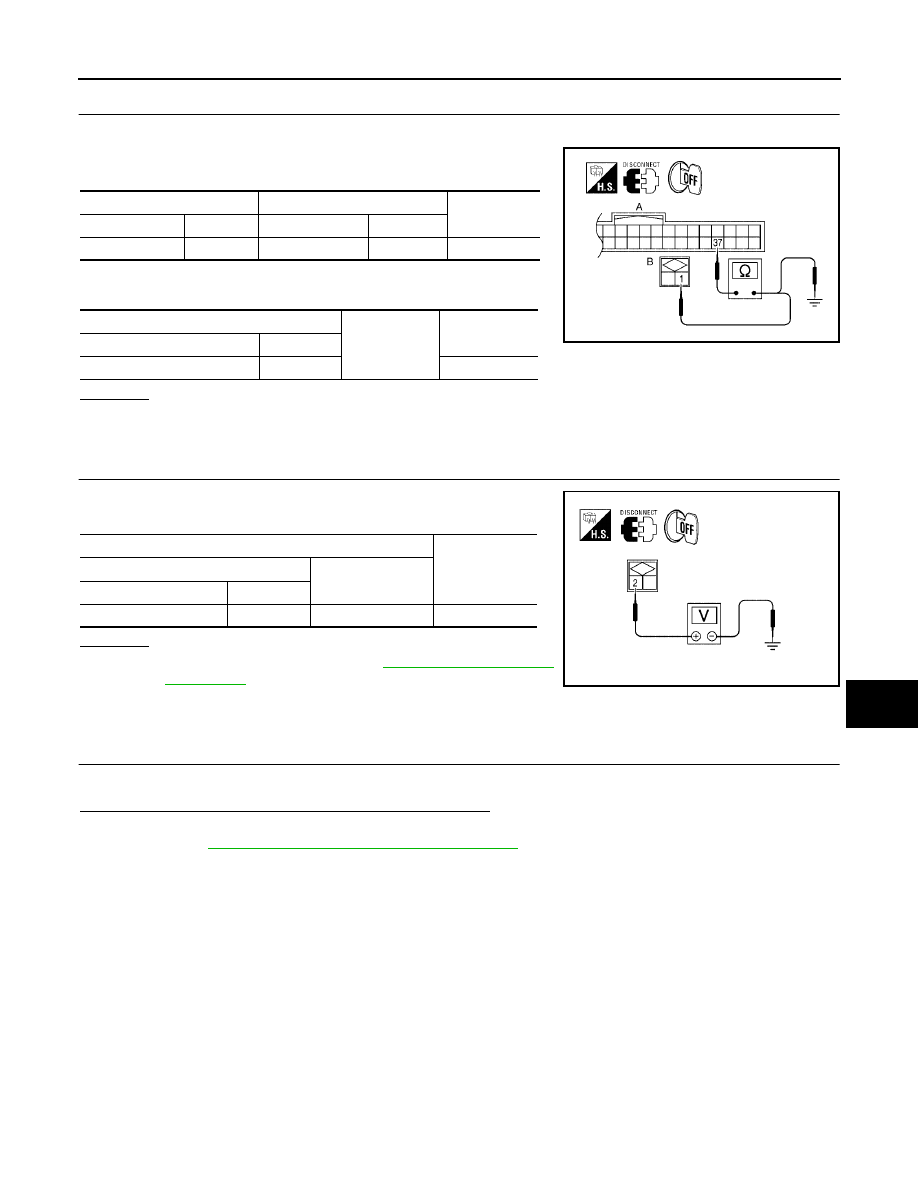

CHECK KEY SWITCH CIRCUIT

1.

Disconnect BCM connector M18.

2.

Check continuity between BCM harness connector M18 (A) ter-

minal 37 and key switch harness connector M27 (B) terminal 1.

3.

Check continuity between BCM harness connector M18 (A) ter-

minal 37 and ground.

OK or NG

OK

>> GO TO 6.

NG

>> Repair harness or connector.

6.

CHECK KEY SWITCH POWER SUPPLY CIRCUIT

Check voltage between key switch harness connector M27 terminal

2 and ground.

OK or NG

OK

>> Replace the BCM. Refer to

NG

>> Check harness for open between fuse and key switch.

Light Warning Chime Does Not Operate

EKS00FZ4

1.

CHECK WARNING CHIME OPERATION

Check key warning chime and seat belt warning chime functions.

Do key warning chime and seat belt warning chime sound?

YES

>> GO TO 2.

NO

>> Go to

DI-53, "All Warning Chimes Do Not Operate"

A

B

Continuity

Connector

Terminal

Connector

Terminal

BCM: M18

37

Key switch: M27

1

Yes

A

Ground

Continuity

Connector

Terminal

BCM: M18

37

No

WKIA4102E

Terminals

Voltage

(Approx.)

(+)

(-)

Key switch connector

Terminal

M27

2

Ground

Battery voltage

WKIA4103E