Nissan Teana J32. Manual - part 848

PB-8

< ON-VEHICLE REPAIR >

PARKING BRAKE SHOE

CAUTION:

The parking brake shoes for the front side are made of different materials from those for the rear

side. Never misidentify them when removing and replacing.

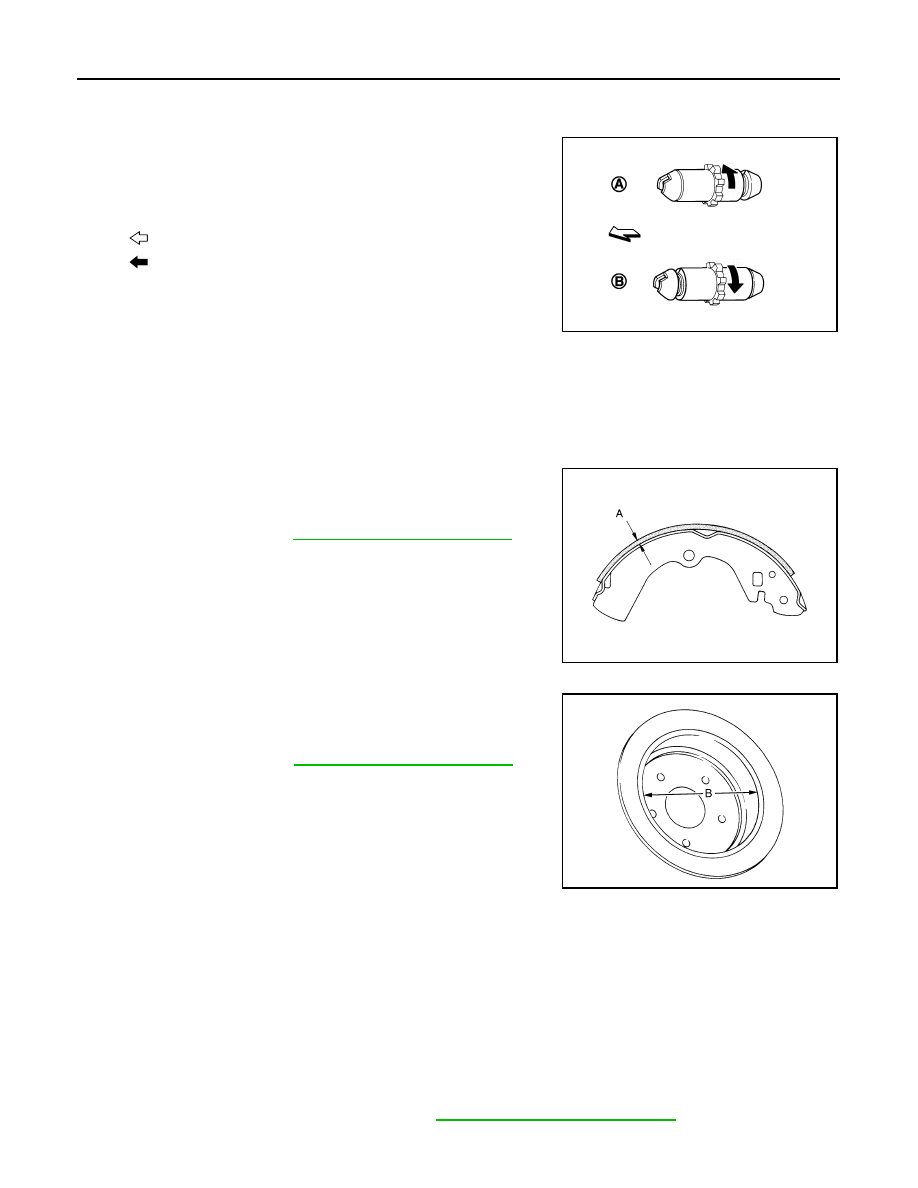

• Assemble adjusters so that threaded part is expanded when rotat-

ing it in the direction shown by arrow.

• Shorten adjuster by rotating it.

• When disassembling, apply PBC (Poly Butyl Cuprysil) grease or

silicone-based grease to threads.

• Check parking brake shoe sliding surface and drum inner surface

for grease. Wipe it off if it adhere on the surfaces.

Inspection and Adjustment

INFOID:0000000003811319

INSPECTION

Brake Lining Thickness Inspection

• Check thickness (A) of brake lining.

Drum Inner Diameter Inspection

• Check inner diameter (B) of drum.

Other Inspections

• Check brake lining for excessive wear, damage, and peeling. Replace if necessary.

• Check parking brake shoe sliding surface for excessive wear and damage. Replace if necessary.

• Check anti-rattle pin and retainer for excessive wear, damage and rust. Replace if necessary.

• Check adjuster spring, anti-rattle spring and return springs for settling, excessive wear, damage, and rust.

Replace if necessary.

• Check adjuster for smoothness. Replace if necessary.

• Check toggle lever for excessive wear, damage and rust. Replace if necessary.

• Visually check inside of the drum for excessive wear, cracks, and damage with a pair of vernier calipers.

Replace if necessary.

ADJUSTMENT

1.

Adjust the parking brake pedal stroke. Refer to

PB-2, "Inspection and Adjustment"

2.

Check a drag of the parking brake.

A

: For RH brake

B

: For LH brake

: Vehicle front

: Adjuster expands

JPFIB0009ZZ

Limit

A

: Refer to

.

SBR021A

Limit

B

: Refer to

.

JPFIB0008ZZ