Nissan Teana J32. Manual - part 666

INTAKE DOOR CONTROL SYSTEM

HAC-33

< FUNCTION DIAGNOSIS >

[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

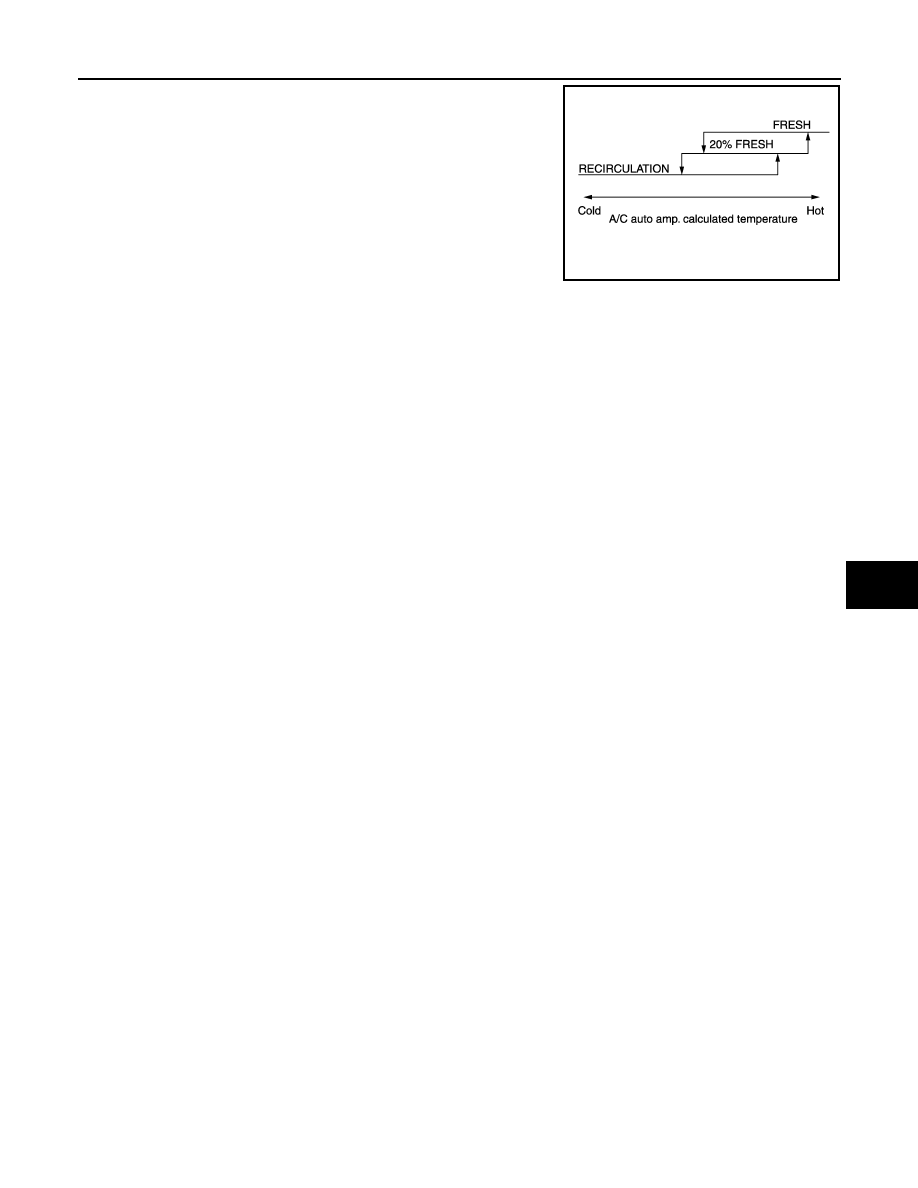

• Intake door position is basically set to the FRE when the FRE indi-

cator is ON or DEF switch is ON.

• Intake door position is basically set to the REC when the REC indi-

cator is ON.

• The intake door automatic control selects the FRE, the 20% FRE,

or the REC depending on the target air mix door opening angle,

based on in-vehicle temperature, ambient temperature, and sun-

load.

JPIIA0634GB