Nissan Teana J32. Manual - part 413

EC-190

< COMPONENT DIAGNOSIS >

[VQ25DE, VQ35DE]

P0138, P0158 HO2S2

Component Inspection

INFOID:0000000003856586

1.

INSPECTION START

Will CONSULT-III be used?

Will CONSULT-III be used?

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

CHECK HEATED OXYGEN SENSOR 2

With CONSULT-III

1.

Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

2.

Start engine and warm it up to the normal operating temperature.

3.

Turn ignition switch OFF and wait at least 10 seconds.

4.

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

5.

Let engine idle for 1 minute.

6.

Select “FUEL INJECTION” in “ACTIVE TEST” mode, and select “HO2S2 (B1)/(B2)” as the monitor item

with CONSULT-III.

7.

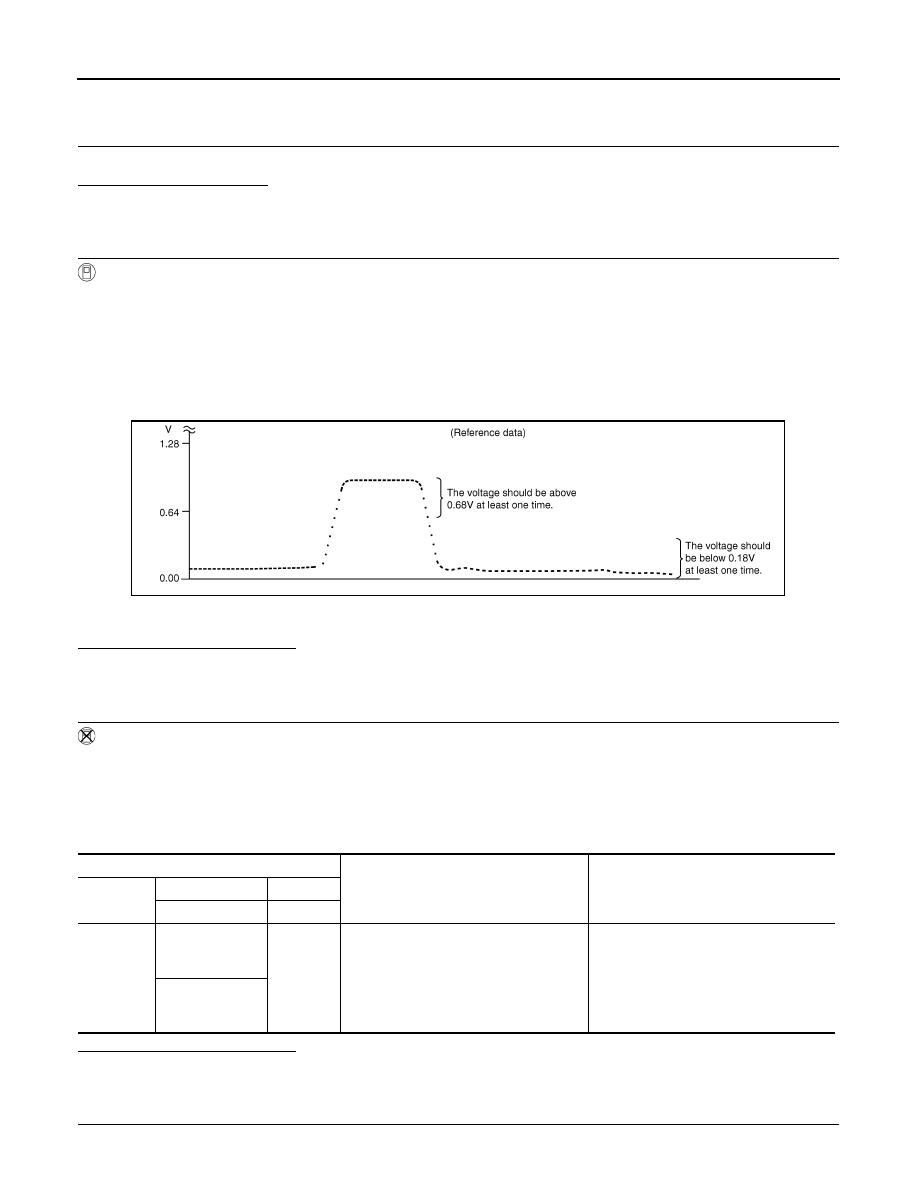

Check “HO2S2 (B1)/(B2)” at idle speed when adjusting “FUEL INJECTION” to

±

25%.

“HO2S2 (B1)/(B2)” should be above 0.68 V at least once when the “FUEL INJECTION” is +25%.

“HO2S2 (B1)/(B2)” should be below 0.18 V at least once when the “FUEL INJECTION” is

−

25%.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 6.

3.

CHECK HEATED OXYGEN SENSOR 2-I

Without CONSULT-III

1.

Start engine and warm it up to the normal operating temperature.

2.

Turn ignition switch OFF and wait at least 10 seconds.

3.

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4.

Let engine idle for 1 minute.

5.

Check the voltage between ECM harness connector terminals under the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 4.

4.

CHECK HEATED OXYGEN SENSOR 2-II

Check the voltage between ECM harness connector terminals under the following conditions.

PBIB3458E

ECM

Condition

Voltage

Connector

+

–

Terminal

Terminal

F8

33

[HO2S2 (bank 1)

signal]

35

(Sensor

ground)

Revving up to 4,000 rpm under no load at

least 10 times

The voltage should be above 0.68 V at

least once during this procedure.

The voltage should be below 0.18 V at

least once during this procedure.

34

[HO2S2 (bank 2)

signal]