Nissan Teana J32. Manual - part 262

BRC-106

< COMPONENT DIAGNOSIS >

[VDC/TCS/ABS]

C1140 ACTUATOR RELAY SYSTEM

C1140 ACTUATOR RELAY SYSTEM

Description

INFOID:0000000003766924

Activates or deactivates each solenoid valve according to the signals transmitted by the ABS actuator and

electric unit (control unit).

DTC Logic

INFOID:0000000003766925

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

DTC REPRODUCTION PROCEDURE

1.

Turn the ignition switch ON.

2.

Perform ABS actuator and electric unit (control unit) self-diagnosis.

Is DTC “C1140” detected?

YES

>> Proceed to diagnosis procedure. Refer to

BRC-106, "Diagnosis Procedure"

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000003766926

1.

CHECK CONNECTOR

1.

Turn the ignition switch OFF.

2.

Disconnect ABS actuator and electric unit (control unit) connector.

3.

Check terminal for deformation, disconnection, looseness, etc.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace damaged parts.

2.

CHECK SOLENOID, VDC SWITCH-OVER VALVE AND ACTUATOR RELAY POWER SUPPLY CIRCUIT

Check the voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace damaged parts.

3.

CHECK SOLENOID, VDC SWITCH-OVER VALVE AND ACTUATOR RELAY GROUND CIRCUIT

Check the continuity between ABS actuator and electric unit (control unit) harness connector and ground.

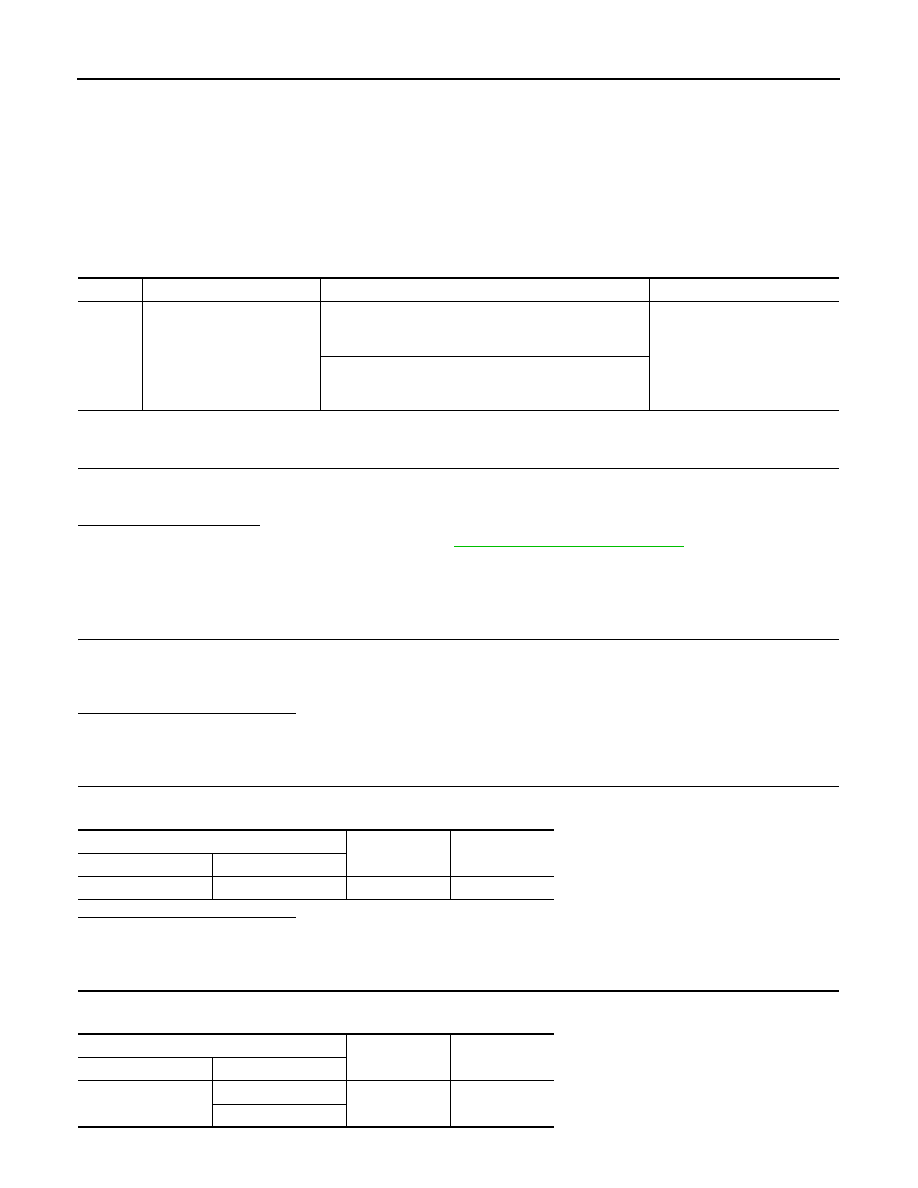

DTC

Display item

Malfunction detected condition

Possible cause

C1140

ACTUATOR RLY

During the actuator relay operating with OFF, when the

actuator relay turns ON, or when the control line for the

relay is shorted to the ground.

• Harness or connector

• ABS actuator and electric unit

(control unit)

During the actuator relay operating with ON, when the

actuator relay turns ON, or when the control line for the

relay is open.

ABS actuator and electric unit (control unit)

—

Voltage

Connector

Terminal

E36

3

Ground

Battery voltage

ABS actuator and electric unit (control unit)

—

Continuity

Connector

Terminal

E36

1

Ground

Existed

4