Nissan Teana J32. Manual - part 231

BRAKE MASTER CYLINDER

BR-27

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

3.

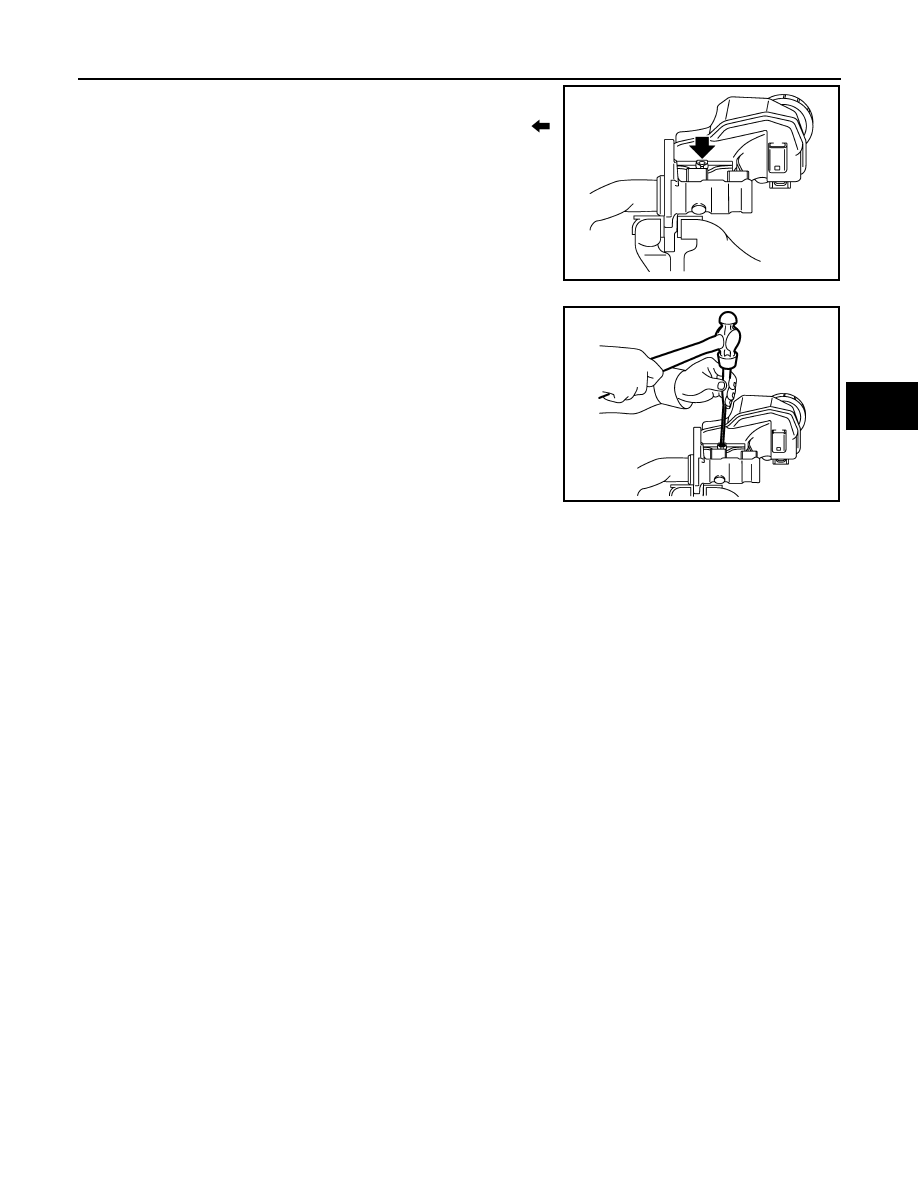

Fix the cylinder body to a vise.

CAUTION:

• Place the reservoir tank with the chamfered pin hole (

)

facing up.

• Always set copper plates or cloth between vise when fix-

ing the cylinder body to a vise. Never overtighten the vise.

4.

Tilt the reservoir tank so that a mounting pin can be inserted.

Insert a mounting pin. Return the reservoir tank to the horizontal

position. Insert another mounting pin into the pin hole on the

opposite side in the same manner after the mounting pin passes

through the cylinder body pin hole.

CAUTION:

Never reuse the mounting pin.

Inspection

INFOID:0000000003811197

INSPECTION AFTER INSTALLATION

Fluid Leak

Check for brake fluid leakage from the cylinder body-to-brake booster mounting face, reservoir tank mounting

face and brake tube connections.

JPFIA0349ZZ

JPFIA0348ZZ