Content .. 1255 1256 1257 1258 ..

Nissan Teana J32. Manual - part 1257

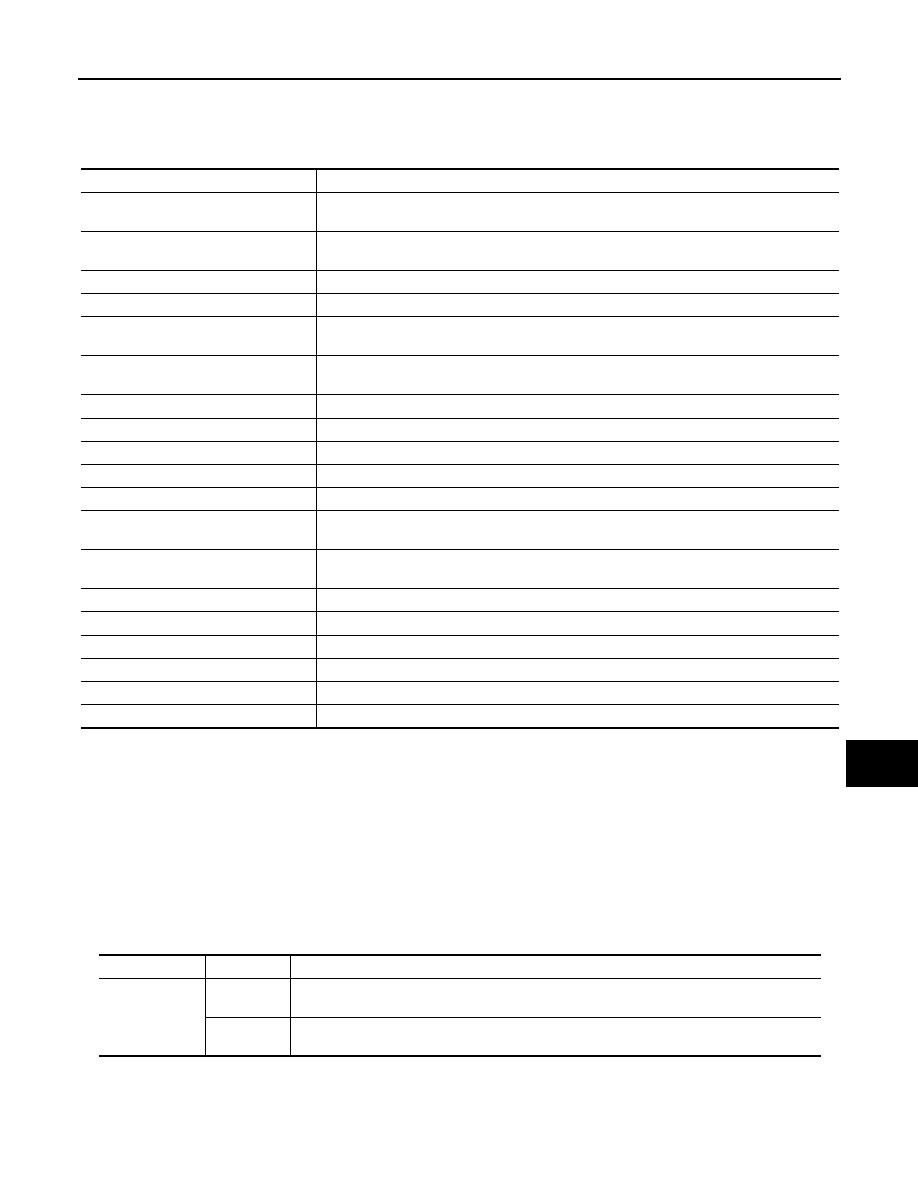

DIAGNOSIS SYSTEM (BCM)

WW-13

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

M

A

B

WW

N

O

P

The BCM records the following condition at the moment a particular DTC is detected.

• Vehicle Speed

• Odo/Trip Meter

• Vehicle Condition (BCM detected condition)

IGN Counter

IGN counter indicates the number of times that ignition switch is turned ON after DTC is detected.

• The number is 0 when a malfunction is detected now.

• The number increases like 1

→

2

→

3...38

→

39 after returning to the normal condition whenever ignition

switch OFF

→

ON.

• The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

WIPER

WIPER : CONSULT-III Function (BCM - WIPER)

INFOID:0000000003761581

WORK SUPPORT

*:Factory setting

NOTE:

When performed “RESET SETTING VALUE” on “Work Support (BCM - BCM)”, set “WIPER SPEED SETTING” on “Work Support (BCM

-WIPER)” to “On”.

CONSULT screen terms

Description

SLEEP>LOCK

While turning BCM status from low power consumption mode to normal mode (Power supply

position is “LOCK”.)

SLEEP>OFF

While turning BCM status from low power consumption mode to normal mode (Power supply

position is “OFF”.)

LOCK>ACC

While turning power supply position from “LOCK” to “ACC”

ACC>ON

While turning power supply position from “ACC” to “IGN”

RUN>ACC

While turning power supply position from “RUN” to “ACC” (Vehicle is stopping and selector

lever is except P position.)

CRANK>RUN

While turning power supply position from “CRANKING” to “RUN” (From cranking up the en-

gine to run it)

RUN>URGENT

While turning power supply position from “RUN“ to “ACC” (Emergency stop operation)

ACC>OFF

While turning power supply position from “ACC” to “OFF”

OFF>LOCK

While turning power supply position from “OFF” to “LOCK”

OFF>ACC

While turning power supply position from “OFF” to “ACC”

ON>CRANK

While turning power supply position from “IGN” to “CRANKING”

OFF>SLEEP

While turning BCM status from normal mode (Power supply position is “OFF”.) to low power

consumption mode

LOCK>SLEEP

While turning BCM status from normal mode (Power supply position is “LOCK”.) to low pow-

er consumption mode

LOCK

Power supply position is “LOCK” (Ignition switch OFF with steering is locked.)

OFF

Power supply position is “OFF” (Ignition switch OFF with steering is unlocked.)

ACC

Power supply position is “ACC” (Ignition switch ACC)

ON

Power supply position is “IGN” (Ignition switch ON with engine stopped)

ENGINE RUN

Power supply position is “RUN” (Ignition switch ON with engine running)

CRANKING

Power supply position is “CRANKING” (At engine cranking)

Service item

Setting item

Description

WIPER SPEED

SETTING

On*

With vehicle speed

(Front wiper intermittent time linked with the vehicle speed and wiper intermittent dial position)

Off

Without vehicle speed

(Front wiper intermittent time linked with the wiper intermittent dial position)