Content .. 1116 1117 1118 1119 ..

Nissan Teana J32. Manual - part 1118

STR-22

< ON-VEHICLE REPAIR >

STARTER MOTOR

VQ35DE : Inspection

INFOID:0000000003860441

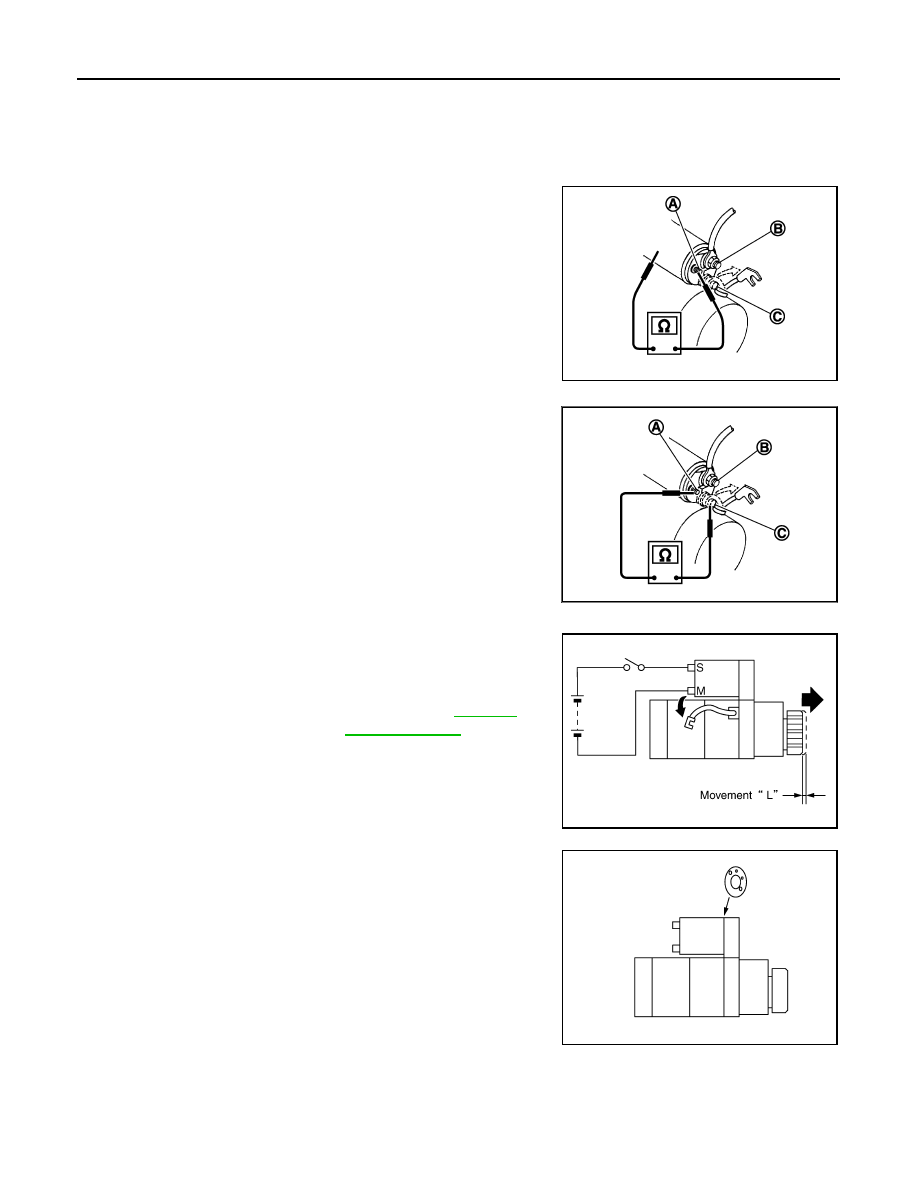

MAGNETIC SWITCH

• Before starting to check, disconnect the battery cable from the negative terminal.

• Disconnect “M” terminal of starter motor.

1.

Continuity test (between “S” terminal and switch body)

• Replace magnetic switch if continuity does not exist.

2.

Continuity test (between “S” terminal and “M” terminal)

• Replace magnetic switch if continuity does not exist.

PINION PROTRUSION LENGTH

• Compare movement “L” in height of pinion when it is pushed out

with magnetic switch energized and when it is pulled out by hand

until it touches stopper.

• If the measurement value is not in the specified area, adjust with

the adjusting plate.

PINION ASSEMBLY

A

: “S” terminal

B

: “B” terminal

C

: “M” terminal

SKIB9002E

A

: “S” terminal

B

: “B” terminal

C

: “M” terminal

SKIB9003E

Movement “L”

SKIB0230E

JPBIA1984ZZ