Content .. 1111 1112 1113 1114 ..

Nissan Teana J32. Manual - part 1113

STR-2

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

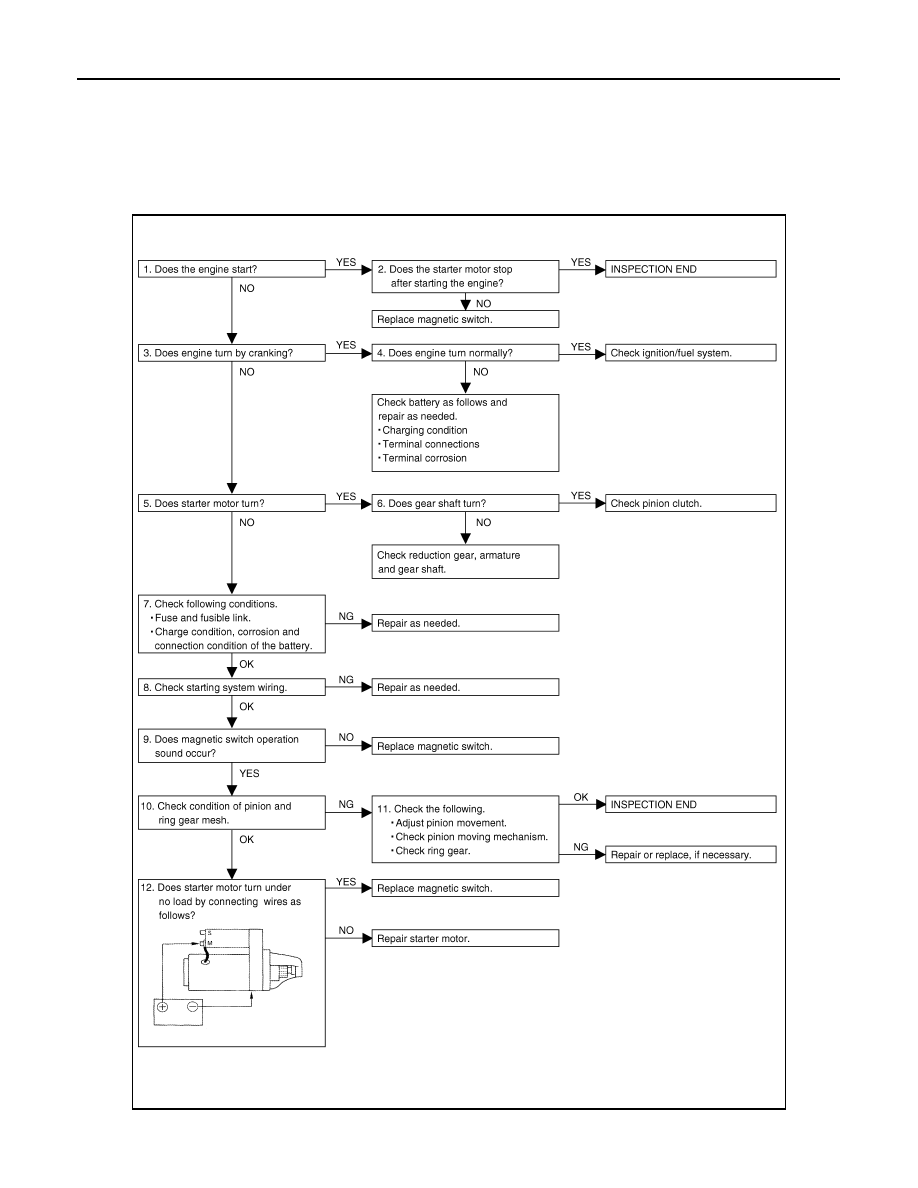

Work Flow

INFOID:0000000003860412

OVERALL SEQUENCE

DETAILED FLOW

JPBIA0502GB