содержание .. 635 636 637 638 ..

Nissan Murano Z51. Manual - part 637

EM-20

< PERIODIC MAINTENANCE >

SPARK PLUG

SPARK PLUG

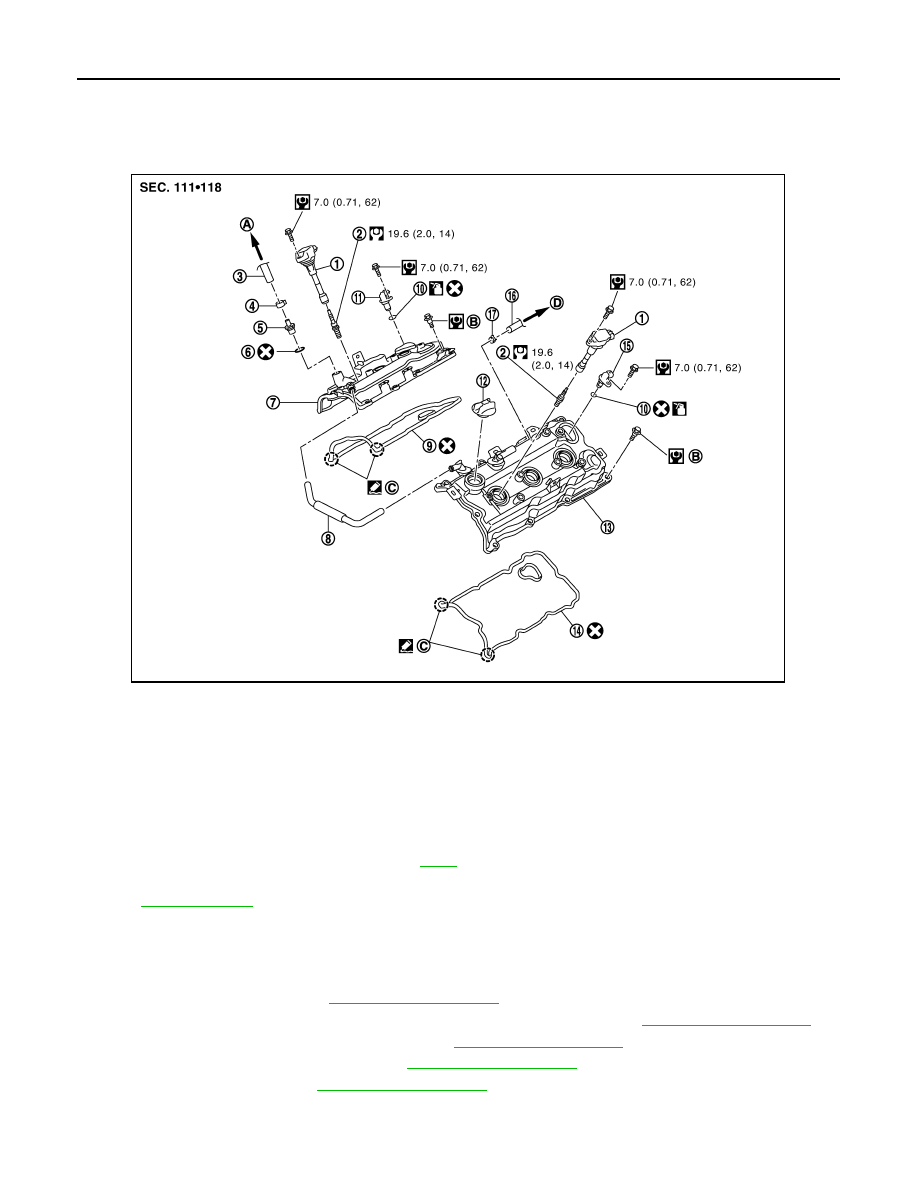

Exploded View

INFOID:0000000005515919

Removal and Installation

INFOID:0000000005515920

REMOVAL

1.

Remove engine cover. Refer to

2.

Remove air cleaner cases (upper and lower) and air duct assembly. Refer to

.

3.

Remove electric throttle control actuator. Refer to

.

4.

Remove intake manifold collector. Refer to

5.

Remove ignition coil. Refer to

.

1.

Ignition coil

2.

Spark plug

3.

PCV hose

4.

Clamp

5.

PCV valve

6.

O-ring

7.

Rocker cover (bank 1)

8.

PCV hose

9.

Rocker cover gasket (bank 1)

10.

O-ring

11.

Camshaft position sensor (PHASE)

(bank 1)

12. Oil filler cap

13.

Rocker cover (bank 2)

14.

Rocker cover gasket (bank 2)

15.

Camshaft position sensor (PHASE)

(bank 2)

16.

PCV hose

17.

Clamp

A.

To intake manifold collector

B.

Refer to

C.

Camshaft bracket side

D.

To air duct

Refer to

for symbols in the figure.

JPBIA1637GB