содержание .. 1196 1197 1198 1199 ..

Nissan Murano Z51. Manual - part 1198

RSU-16

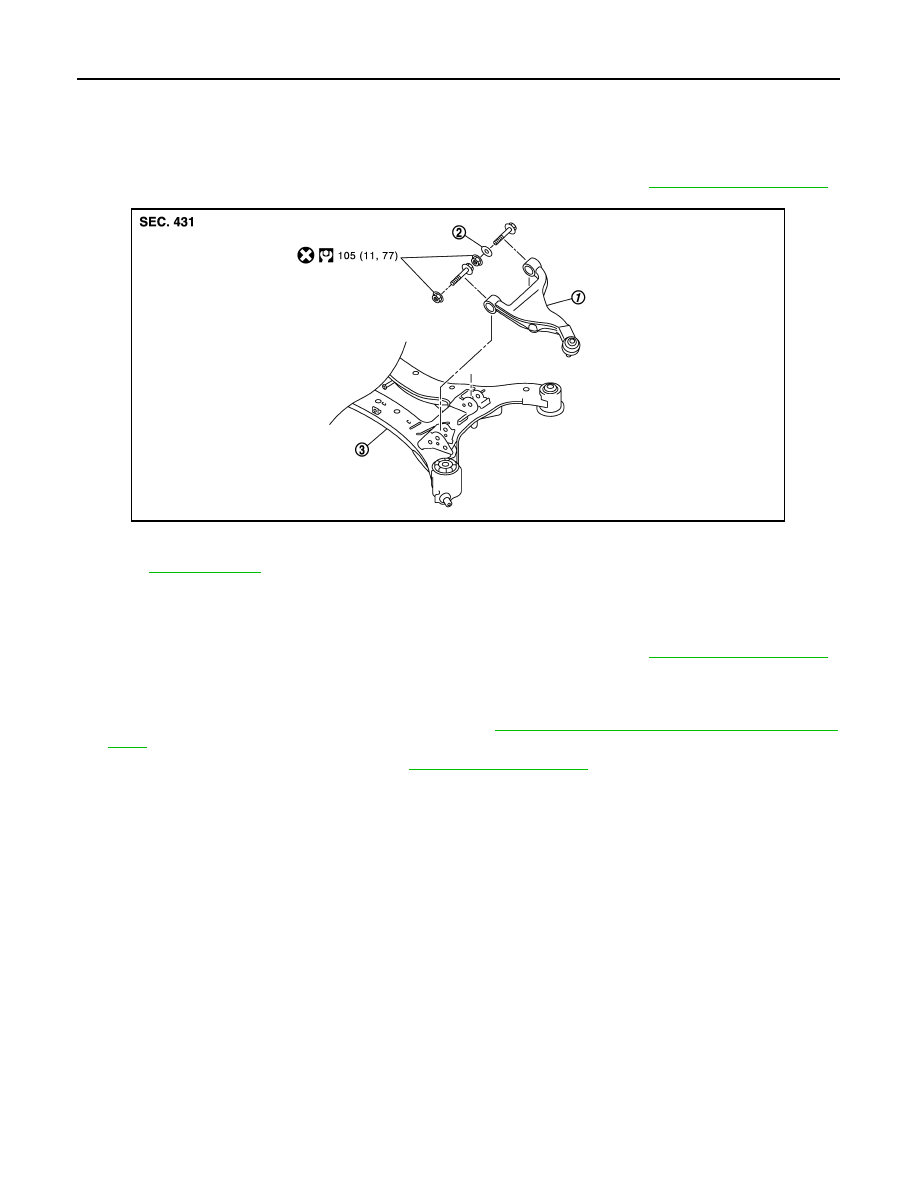

< REMOVAL AND INSTALLATION >

REAR SUSPENSION ARM

REAR SUSPENSION ARM

Exploded View

INFOID:0000000005514363

NOTE:

Remove suspension arm with rear suspension member for AWD models. Refer to

.

Removal and Installation

INFOID:0000000005514364

NOTE:

Remove suspension arm with rear suspension member for AWD models. Refer to

.

REMOVAL

1.

Remove tire with power tool.

2.

Remove wheel sensor and sensor harness. Refer to

BRC-111, "REAR WHEEL SENSOR : Exploded

.

3.

Remove stabilizer connecting rod. Refer to

.

4.

Remove cotter pin of suspension arm ball joint, and loosen nut.

5.

Use the ball joint remover to remove suspension arm from axle housing. Be careful not to damage ball

joint boot.

CAUTION:

Tighten temporarily mounting nut to prevent damage to threads and to prevent ball joint remover

from coming off.

6.

Remove suspension arm.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Perform final tightening of rear suspension member installation position (rubber bushing), under unladen

conditions with tires on level ground.

Inspection

INFOID:0000000005514365

INSPECTION AFTER REMOVAL

Appearance

Check the following items, and replace the part if necessary.

• Suspension arm and bushing for deformation, cracks or damage.

• Boot of ball joint for cracks or damage, and also for grease leakage.

1.

Suspension arm

2.

Stopper rubber

3.

Rear suspension member

Refer to

for symbols in the figure.

JPEIB0141GB