Murano Cross Cabriolet Z51 (2013 year). Manual - part 100

STR-10

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORK FLOW

Is “S” connector circuit normal?

YES

>> GO TO 9.

NO

>> Repair as needed.

9.

ENGINE ROTATION STATUS

Check that the engine can be rotated by hand.

Does the engine turn freely by hand?

YES

>> Replace starter motor. Refer to

STR-16, "Removal and Installation"

NO

>> Perform further diagnosis of engine mechanical or powertrain mechanism. Once resolved, per-

form battery test again using Multitasking battery and electrical diagnostic station GR8-1200 NI.

Refer to the diagnostic station Instruction Manual for proper testing procedures.

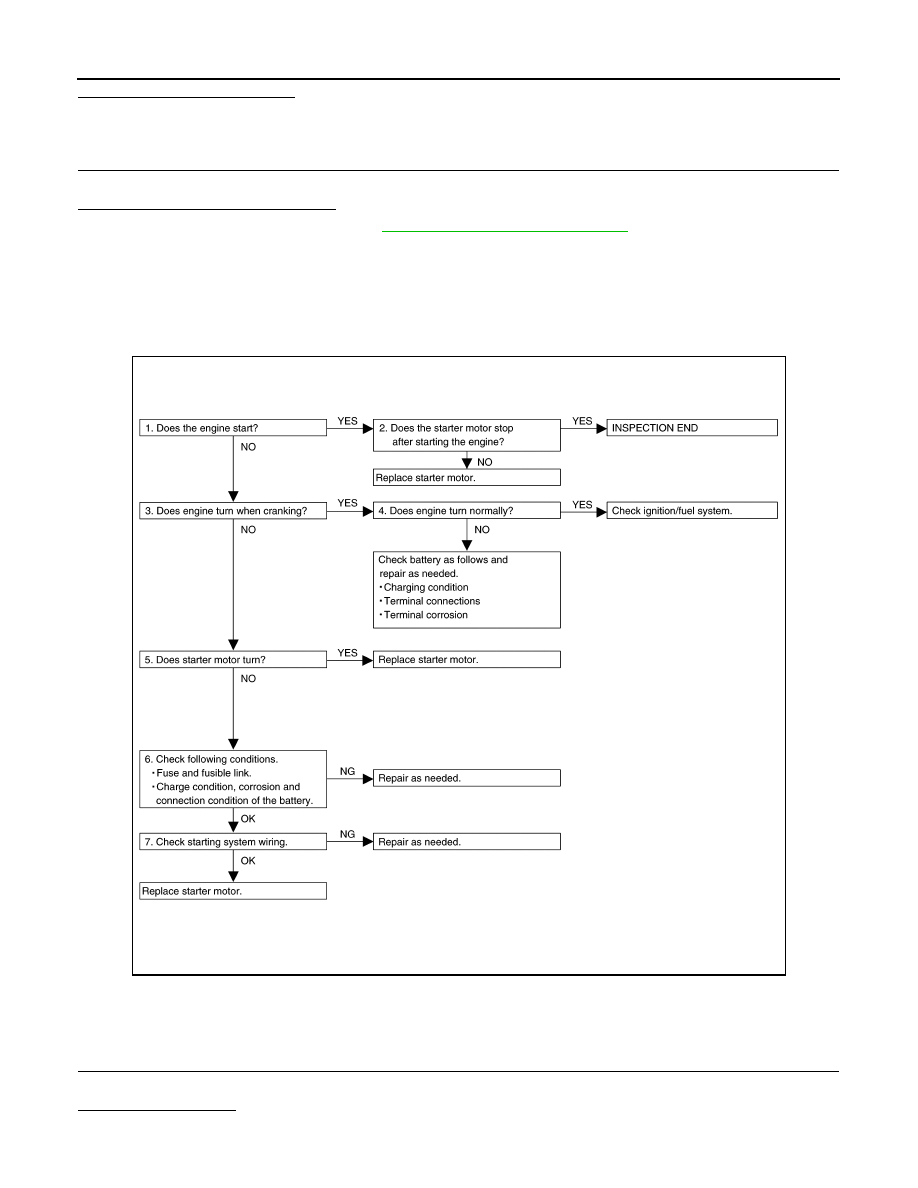

Work Flow (Without GR8-1200 NI)

INFOID:0000000008954750

OVERALL SEQUENCE

DETAILED FLOW

NOTE:

If any malfunction is found, immediately disconnect the battery cable from the negative terminal.

1.

CHECK ENGINE START

Crank the engine and check that the engine starts.

Does the engine start?

YES

>> GO TO 2.

JMBIA4454GB

Revision: 2012 October

2013 Murano CrossCabriolet